Nano mold flux for continuous casting crystallizer and preparation method thereof

A technology for continuous casting mold and mold flux, which is applied in the field of continuous casting mold nano-mold flux and its preparation, can solve the problems that the mold flux is difficult to meet the requirements, and achieve the advantages of large-scale production and industrial application, good sphericity, The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

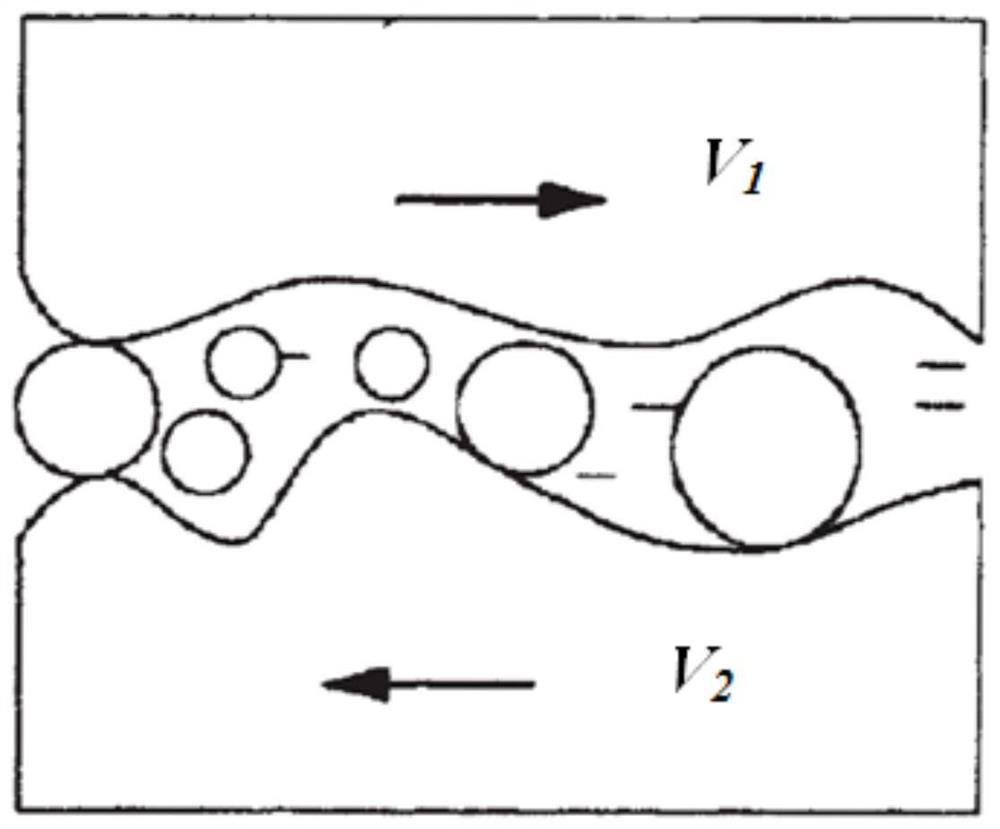

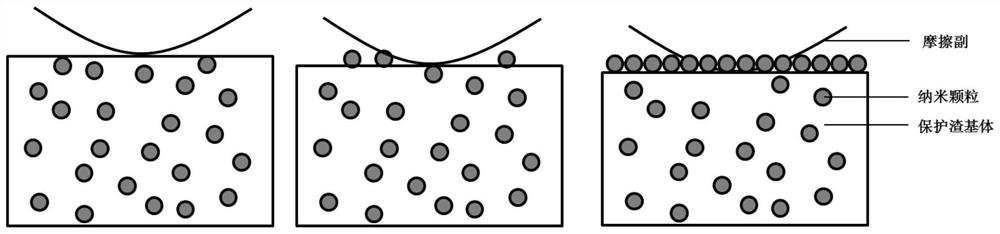

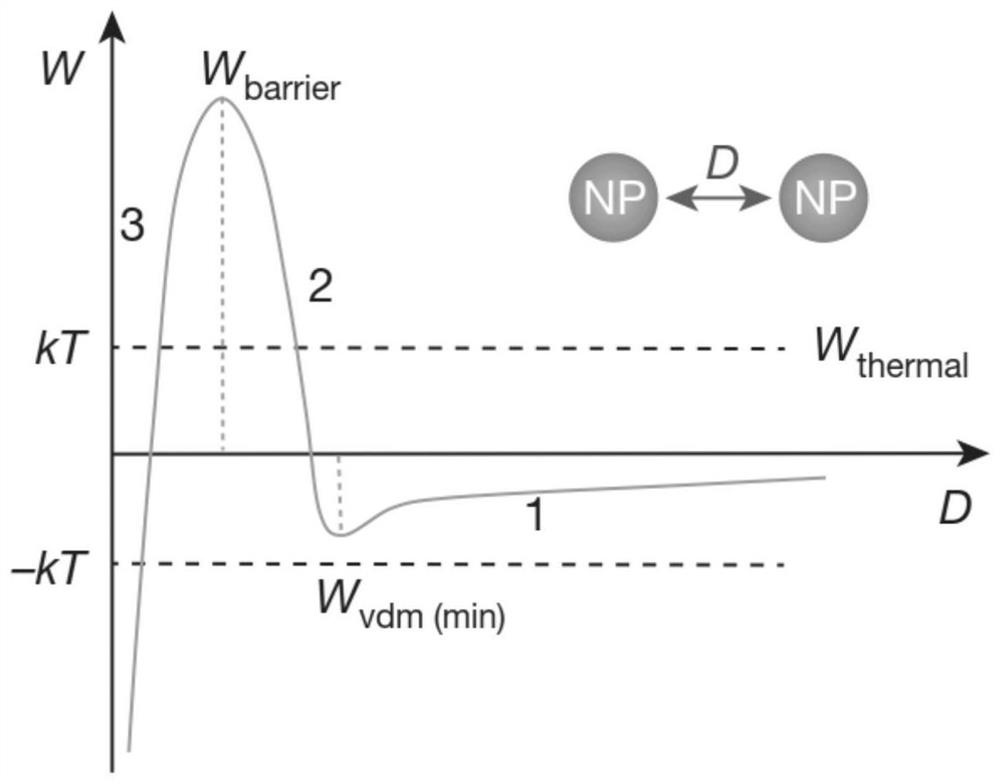

Method used

Image

Examples

Embodiment 1

[0033] A kind of continuous casting crystallizer nano mold powder is prepared, and its preparation method comprises the following steps:

[0034] (1) Select spherical nano-silicon carbide ceramic particles with intrinsic thermal conductivity of 100w / mk, particle size of 100nm, self-friction coefficient of 0.3, and self-lubricating properties, and disperse them by mechanical stirring for 3 hours to form dispersed spherical nano-silicon carbide ceramics granular system;

[0035] (2) The dispersed spherical nano-silicon carbide ceramic particle system obtained in 1ml step (1) is added to 1000ml with SiO 2 -CaO-Al 2 o 3 In the solid mold flux based on the powder, the volume ratio of nano-silicon carbide ceramic particles in the mold flux is 0.1%, and then high-energy ball milling at a speed of 100rpm is carried out. The ball milling time is 30min. After the ball milling, a continuous casting can be obtained. Crystallizer nano powder.

[0036] In addition, the chemical dispersa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com