Tower-shaped repairing mode of cold hard rolled plates for bundling strip raw materials

A tower-shaped, cold-hard technology, applied in the field of repair means, can solve the problems of steel coil tower shape, delay in supply cycle, and high content of smelting component C, so as to improve the qualified rate and finished product rate, improve the finished product rate and qualified rate, The effect of expanding profit margins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

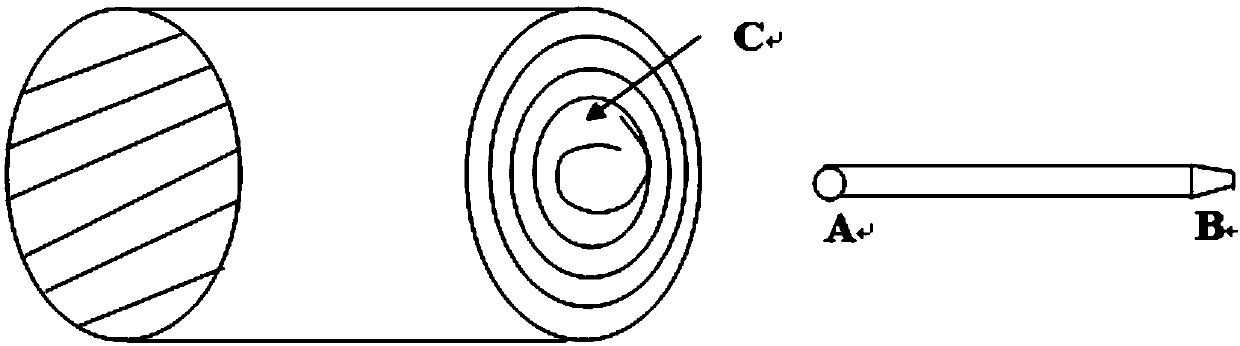

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0019] The tower-shaped chilled steel coil used for repairing strapping raw materials requires spare tools: a 1.5m-2m long hard wooden stick, 2 pairs of thick gloves, and an eight-pound hand hammer.

[0020] Since the market demand for chilled coils for strapping raw materials is mostly 0.6mm to 0.9mm in thickness, and the specifications are thin, two workers can complete the repair of tower-shaped steel coils with normal operations, which greatly improves the yield of cold-rolled products. And the pass rate has brought considerable economic benefits to the steel mills.

[0021] Repair tools: 1.5m~2m long hard wooden stick (cylindrical at one end, flat at the other end, diameter Φ=30mm~40mm is the best); 2 pairs of thick gloves; an eight-pound h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com