High-protein Tibetan nettle biscuit and processing and applying method thereof

A technology of processing method and application method, applied in the field of animal husbandry, can solve the problems of low productivity of sheep, lack of high-protein forage, long slaughtering cycle, etc., and achieve the effect of improving sheep productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

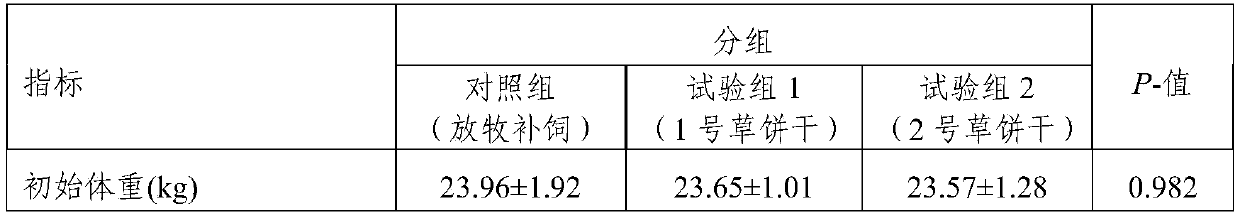

[0036] Processing of high-protein Tibetan nettle grass biscuits: When the Tibetan nettle grows to the suitable harvesting period, that is, the flowering period (July-August), the whole plant is mowed, and the stubble height is 5cm. Naturally air-dried until the moisture content is lower than 20% (18.3% measured in this embodiment), crushed into 2 to 3 cm long, blended with Tibetan nettle 99.5% and table salt 0.5% by weight, and mixed evenly. Using straw briquetting equipment, start the machine and preheat for 5 minutes before feeding, and press the Tibetan nettle and salt mixed feed to a density of 544kg / m 3 Grass Biscuits (Number 1 Grass Biscuits).

[0037] The physical properties and nutritional analysis of the grass biscuits in this embodiment are as follows: the harvest period and water content of Tibetan nettles are strictly controlled in the present invention, so as to process Tibetan nettle whole grass biscuits with suitable density and hardness. The grass biscuit proc...

Embodiment 2

[0039]On the basis of Example 1, the Tibetan nettles cut in the manner of Example 1 were aired in the field until the moisture content reached about 20% (actually measured as 19.9%), and then pulverized, and the pulverized length was 2 to 3 cm. Purchase soybean meal, cornmeal and salt from local feed mills. According to the proportion by weight, it is 60% of Tibetan nettle, 3.5% of soybean meal, 36% of corn flour and 0.5% of table salt, fully mixed evenly, and pressed with straw briquetting equipment to a density of 597kg / m 3 The Whole Mix Grass Biscuits (No. 2 Grass Biscuits).

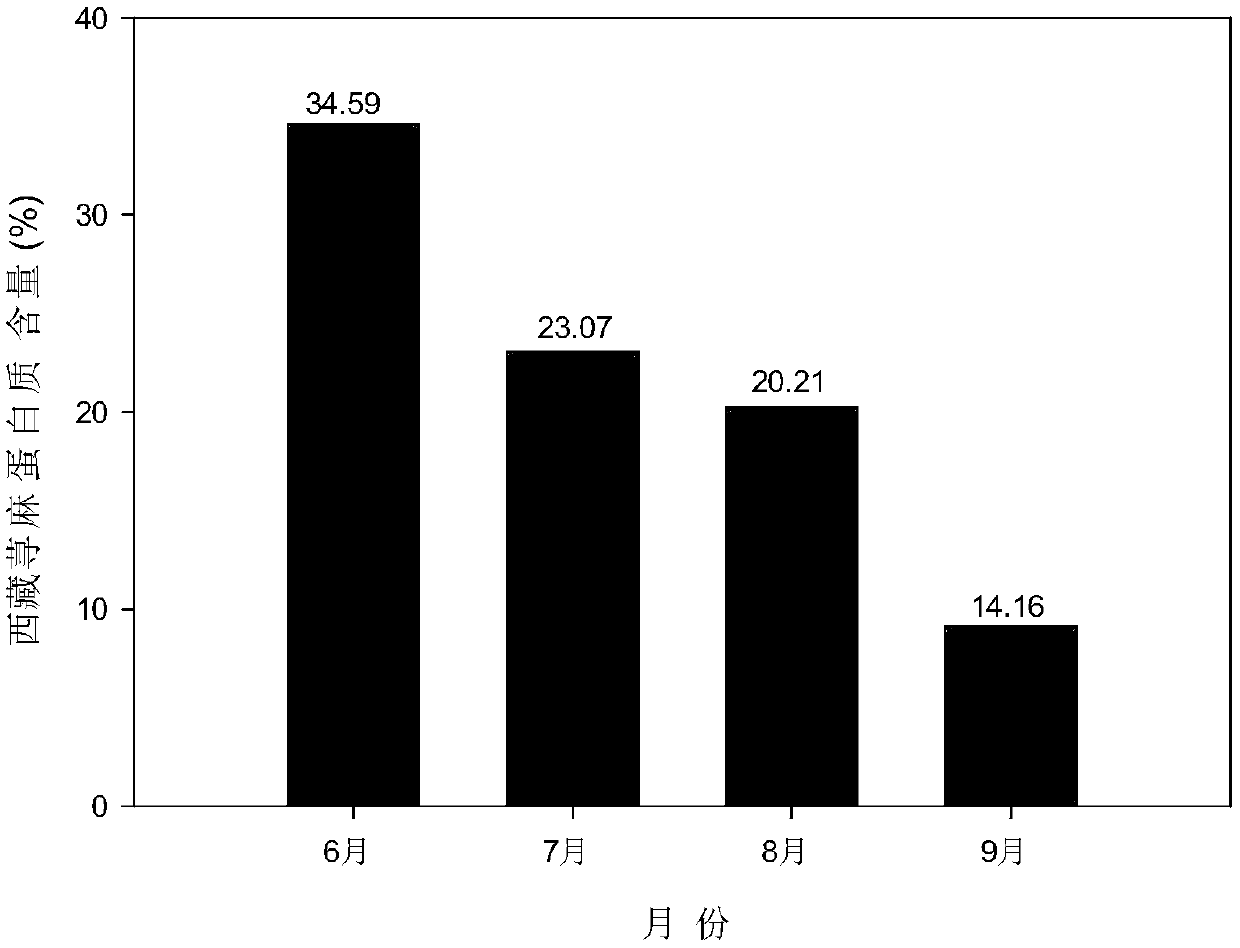

[0040] The technical effect of the present embodiment: Tibetan nettle self protein content is very high, and the crude protein content of the whole plant in flowering late stage in August is 20.21%, reaches the crude protein content (≥20.0%) of high-grade alfalfa hay; Higher than Tibet local market simultaneously The crude protein content (16.2%) of the goat concentrate supplement feed sold. In this...

Embodiment 3

[0042] On the basis of Example 1, the Tibetan nettles cut in the manner of Example 1 were aired in the field until the moisture content reached about 20% (actually measured as 19.9%), and then pulverized, and the pulverized length was 2 to 3 cm. According to the proportion by weight, it is 50% of Tibetan nettle, 6.5% of soybean meal, 43% of corn flour and 0.5% of table salt, fully mixed evenly, and pressed with straw briquetting equipment to a density of 596kg / m 3 The Whole Mix Grass Biscuits (No. 3 Grass Biscuits).

[0043] In this example, the consumption of soybean meal and corn flour is increased for the grass biscuit, and the cost is greatly increased; in view of the fact that the nutrition provided by the No. 2 grass biscuit is sufficient for the growth of sheep, the economic value of the No. 2 grass biscuit is better. comparative example

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com