Construction method of antimony tellurium selenium matrix alloy for thermoelectric material and antimony tellurium selenium-based thermoelectric material

A technology of thermoelectric materials and matrix alloys, applied in the direction of thermoelectric device lead-out wire materials, thermoelectric device manufacturing/processing, etc., can solve the problems of incapable of mass industrial production and high preparation costs, and achieve the effect of low cost and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] (1) Pulverize Sb blocks, Te blocks and Se blocks with a commercial purity of 5N;

[0055] (2) Pour dilute nitric acid solution into a quartz tube with an inner diameter of about 12mm sealed at one end, ultrasonically clean it for 15-20 minutes, then wash it twice with water and once with absolute ethanol, and then put the quartz tube in an oven at 100°C Dry for 8 hours;

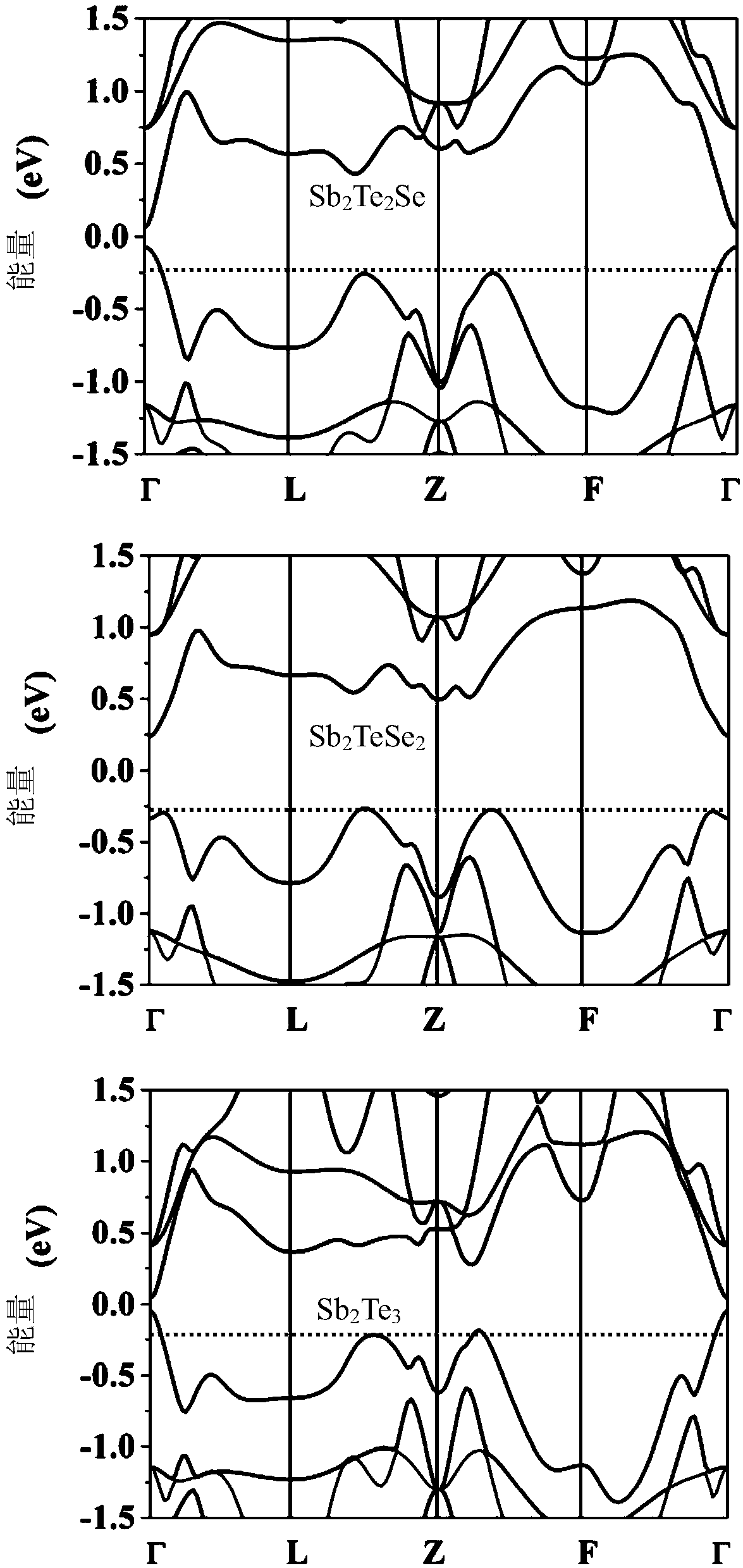

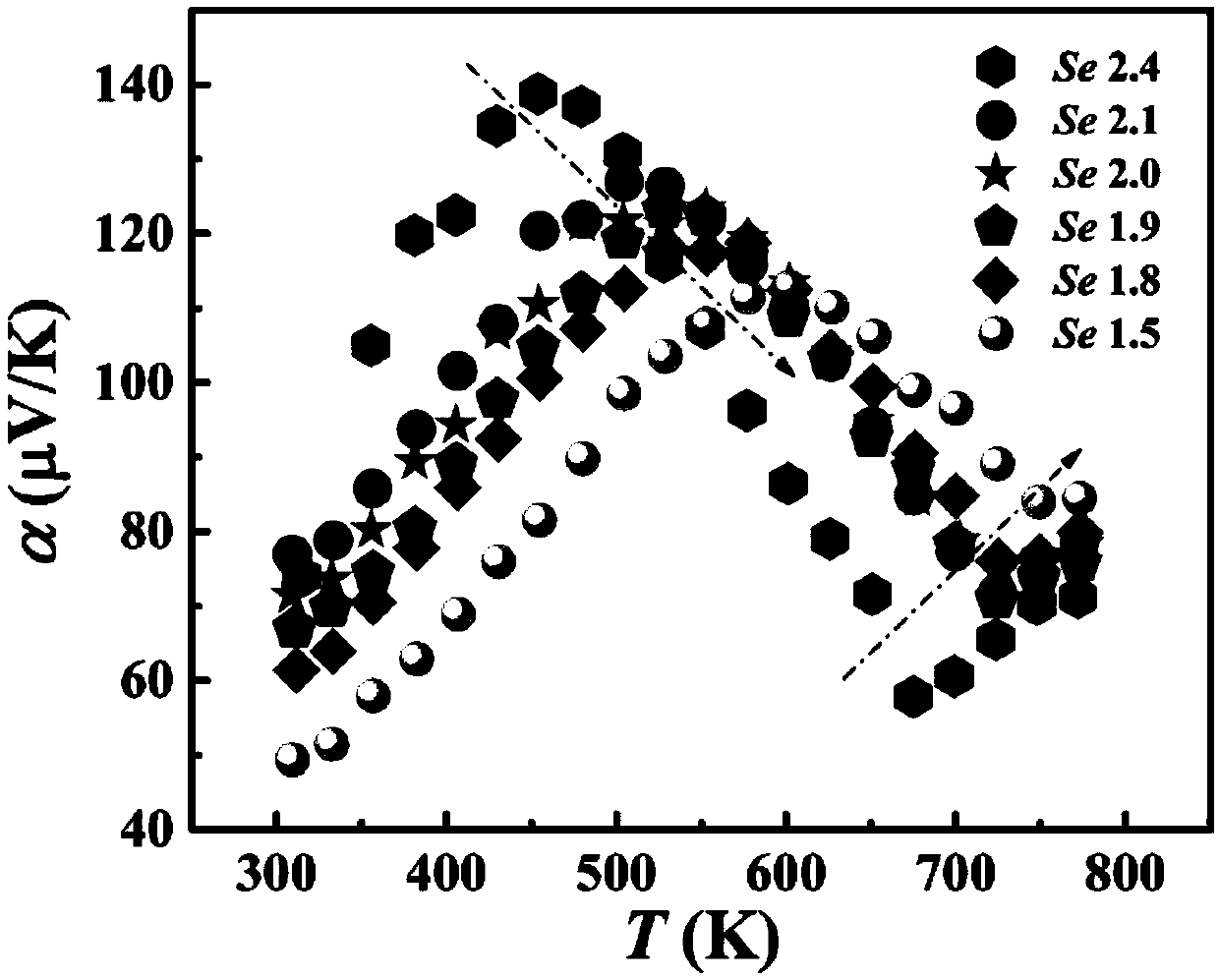

[0056] (3) According to the chemical formula Sb 2 Te 3-x Se x The stoichiometric ratio of each element in the step (1) is taken by weighing a total of 80g of raw materials, and put into a dried quartz tube, wherein x=1.5, 1.8, 1.9, 2.0, 2.1, 2.4, 2.7;

[0057] (4) the vacuum degree of quartz tube in step (3) is pumped to 10 -3 Pa, and seal the other end of the quartz tube with an oxyhydrogen flame;

[0058] (5) Melting the quartz tube in step (4) in a rotary melting furnace at 800°C for 10 hours, rotating continuously during the melting process to ensure sufficient mixing of raw materials, cooling...

Embodiment 2

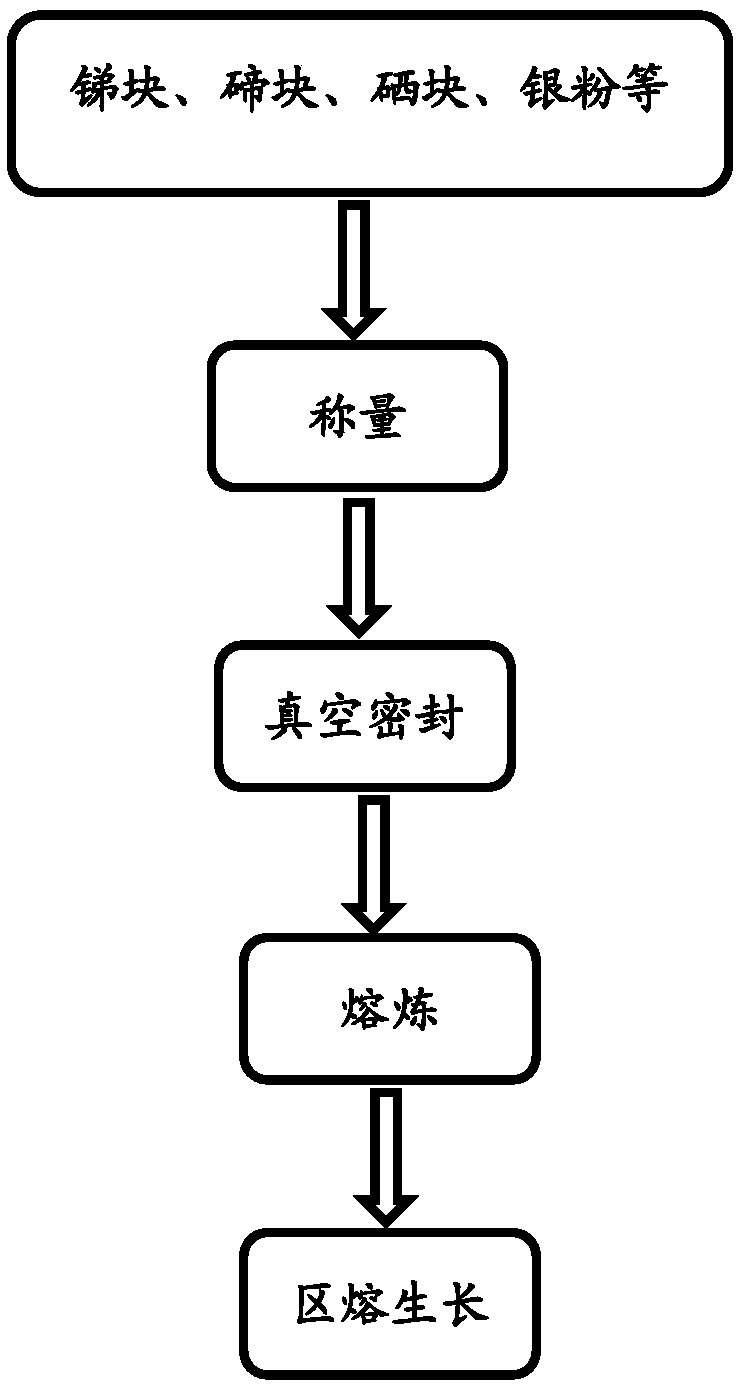

[0067] Such as figure 2 As shown, the preparation method of antimony tellurium selenide based thermoelectric material is as follows:

[0068] (1) Pulverize Sb blocks, Ag blocks, Te blocks and Se blocks with a commercial purity of 5N;

[0069] (2) Pour dilute nitric acid solution into a quartz tube with an inner diameter of about 12mm sealed at one end, ultrasonically clean it for 15-20 minutes, then wash it twice with water and once with absolute ethanol, and then put the quartz tube in an oven at 100°C Dry for 8 hours;

[0070] (3) Add the dopant Ag, according to the chemical formula Sb2-y Ag y TeSe 2 The stoichiometric ratio of each element in the step (1) takes by weighing 80g of raw materials altogether, puts in the quartz tube after drying, wherein y=0.005~0.03;

[0071] (4) the vacuum degree of quartz tube in step (3) is pumped to 10 -3 Pa, and seal the other end of the quartz tube with an oxyhydrogen flame;

[0072] (5) Melting the quartz tube in step (4) in a ro...

Embodiment 3

[0077] (1) Pulverize Sb lumps, Ag lumps, Pb lumps, Cu lumps, Te lumps and Se lumps with a commercial purity of 5N;

[0078] (2) Pour dilute nitric acid solution into a quartz tube with an inner diameter of about 12mm sealed at one end, ultrasonically clean it for 15-20 minutes, then wash it twice with water and once with absolute ethanol, and then put the quartz tube in an oven at 100°C Dry for 8 hours;

[0079] (3) Add dopant Ag block, Pb block, Cu block, according to the chemical formula Sb 1.98-z Ag 0.02 Cu z TeSe 2 , Sb 1.98- m Ag 0.02 Pb m TeSe 2 The stoichiometric ratio of each element in the step (1) takes by weighing 80g of raw materials altogether, puts in the quartz tube after drying, wherein z=0.005~0.015, m=0.005~0.015;

[0080] (4) the vacuum degree of quartz tube in step (3) is pumped to 10 -3 Pa, and seal the other end of the quartz tube with an oxyhydrogen flame;

[0081] (5) Melting the quartz tube in step (4) in a rotary melting furnace at 800°C fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com