Foundation reinforcement device and method

A technology for foundation reinforcement and foundation area, which is used in infrastructure engineering, soil protection, construction, etc., can solve the problems of low grouting efficiency and difficulty in fully injecting the slurry into the soil, and achieve the effect of improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

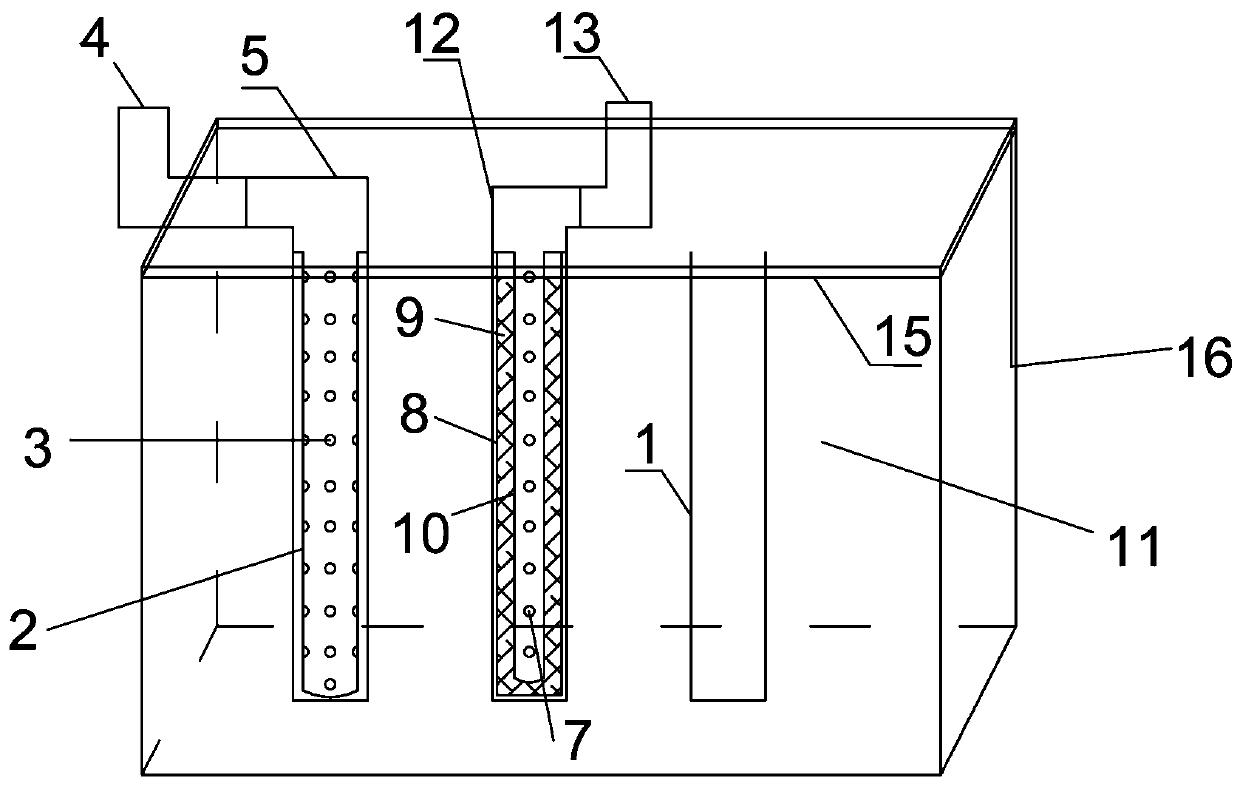

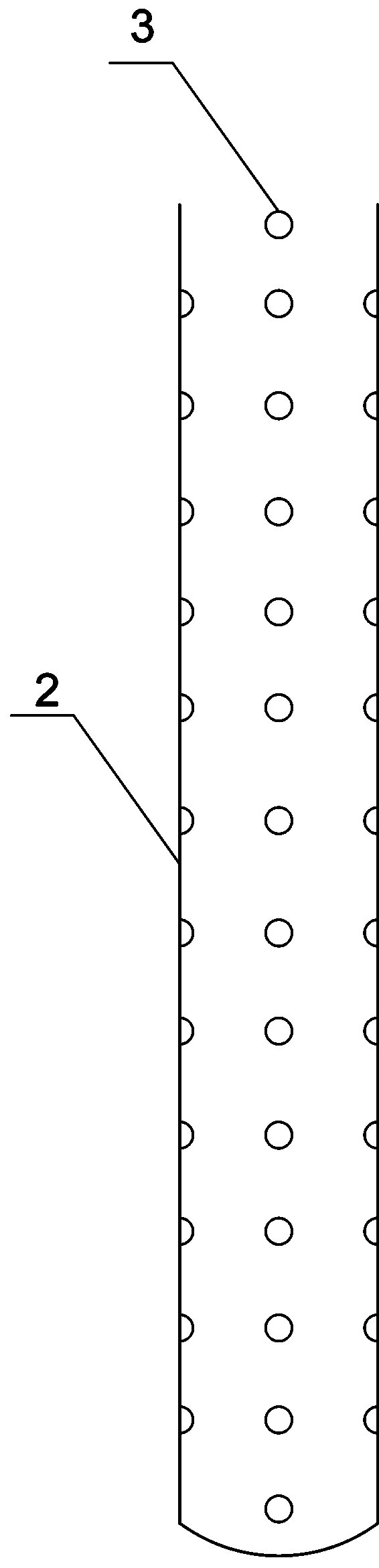

[0036] Such as Figure 1-Figure 3 As shown, a foundation reinforcement device includes spacers 16 with open upper and lower end surfaces inserted into the soil around the foundation area 11 to be reinforced. The foundation area 11 to be reinforced is evenly arranged with N columns of boreholes 1, and each column drills The number of holes 1 is M, N≥2, M≥1, the grouting device and the suction device are respectively matched with the drilling 1; the top surface of the foundation area 11 to be reinforced is laid with an isolation film 15, and the foundation area to be reinforced 11 The edge position is closed and connected with the isolation film 15;

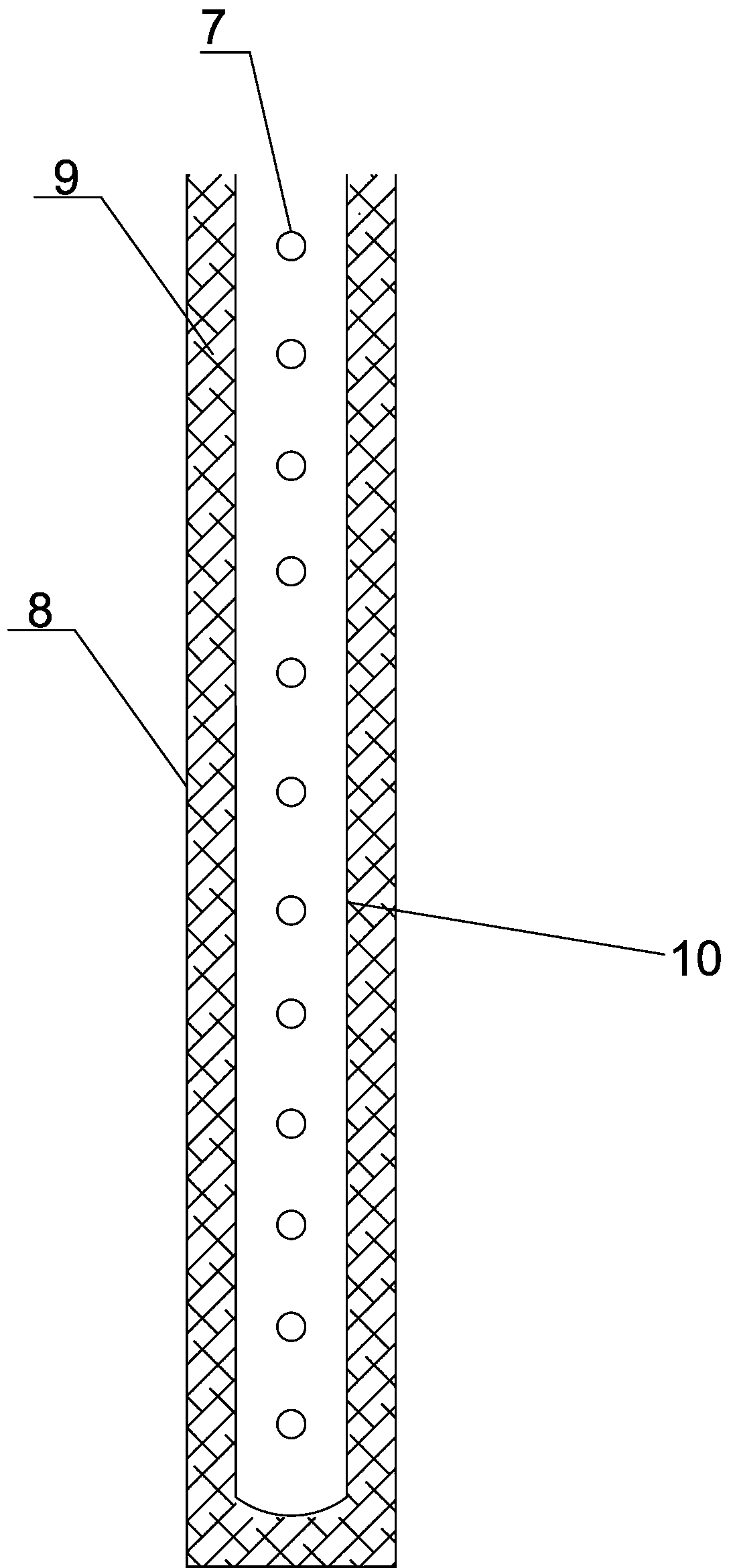

[0037] The suction device includes a suction pipe body, the suction pipe body includes a suction pipe 10 with an open top, the pipe wall of the suction pipe 10 is evenly arranged with a plurality of suction holes 7, and the suction pipe 10 is covered with a metal mesh. Layer 8, the space between the suction pipe 10 and the metal m...

Embodiment 2

[0043] Such as Figure 4 Shown, a kind of method that adopts above-mentioned device to carry out foundation reinforcement, this method comprises the following steps:

[0044] Step 1: Determine the foundation area 11 to be reinforced, and insert the isolation body 16 into the soil outside the foundation area 11 to be reinforced;

[0045] Step 2: Drill N columns of boreholes 1 in the foundation area 11 to be reinforced, the number of each column of boreholes 1 is M, N=2, M≥1; the distance between every two boreholes 1 is much greater than The diameter of the borehole 1 (preferably 2-5 times the diameter);

[0046] Step 3: Lay an isolation film 15 on the top surface of the foundation area 11 to be reinforced, and seal and connect the edge of the foundation area 11 to be reinforced with the isolation film 15;

[0047] Step 4: Drill holes at the appropriate positions of the isolation membrane 15 in the foundation area 11 to be reinforced, insert the grouting pipe 2 into each dril...

Embodiment 3

[0051] Such as Figure 5 Shown, a kind of method that adopts above-mentioned device to carry out foundation reinforcement, this method comprises the following steps:

[0052] Step 1: Determine the foundation area 11 to be reinforced, and insert the isolation body 16 into the soil outside the foundation area 11 to be reinforced;

[0053] Step 2: Drill N columns of boreholes 1 in the foundation area 11 to be reinforced, the number of each column of boreholes 1 is M, N>2, M≥1; the distance between every two boreholes 1 is much greater than The diameter of the borehole 1 (preferably 2-5 times the diameter);

[0054] Step 3: Lay an isolation film 15 on the top surface of the foundation area 11 to be reinforced, and seal and connect the edge of the foundation area 11 to be reinforced with the isolation film 15;

[0055] Step 4: Drill holes at appropriate positions in the foundation area 11 to be reinforced, insert the grouting pipe 2 into each drill hole 1 of the first row of dril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com