Processing equipment for high-strength air-jet vortex spinning yarn

A technology of vortex spinning and processing equipment, which is applied to spinning machines, open-end spinning machines, continuous winding spinning machines, etc., and can solve the problem of low frictional adhesion of synthetic fiber yarns and insufficient cohesion between fibers. , affecting the yarn strength and other issues, to achieve the effects of improving strength and wear resistance, increasing cohesion, and increasing friction and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further elaborated below by means of the accompanying drawings and examples.

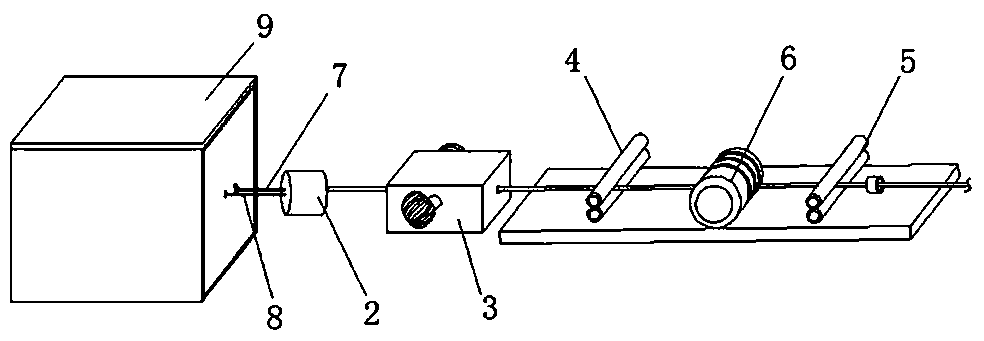

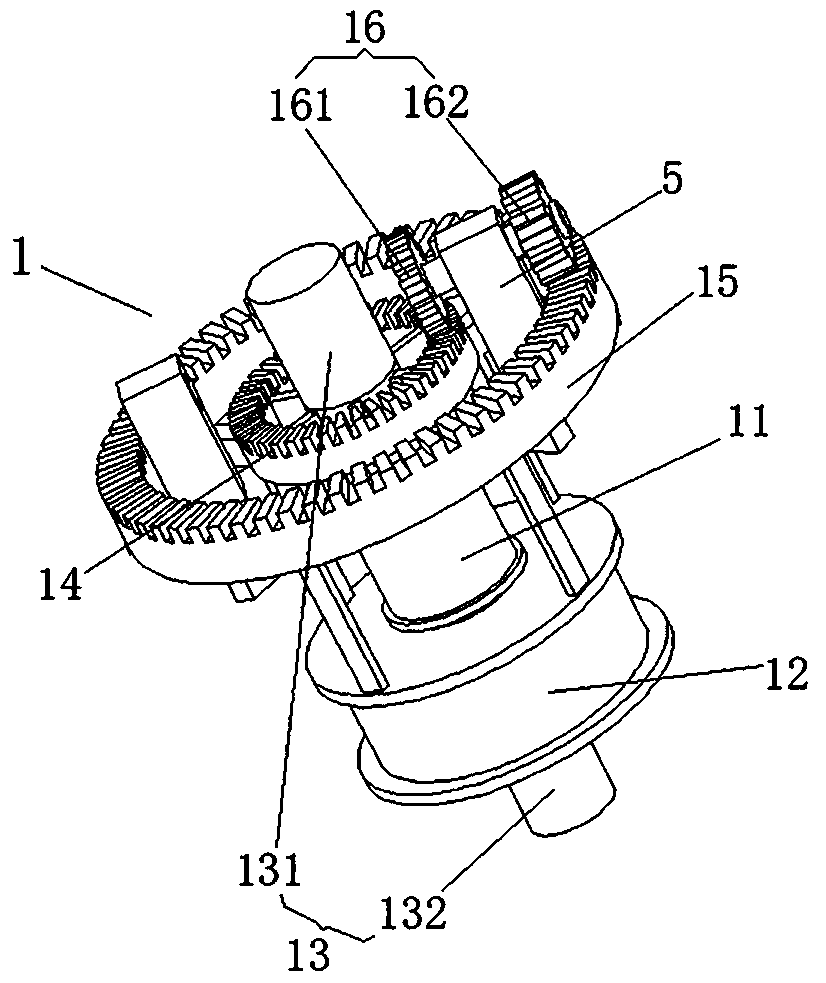

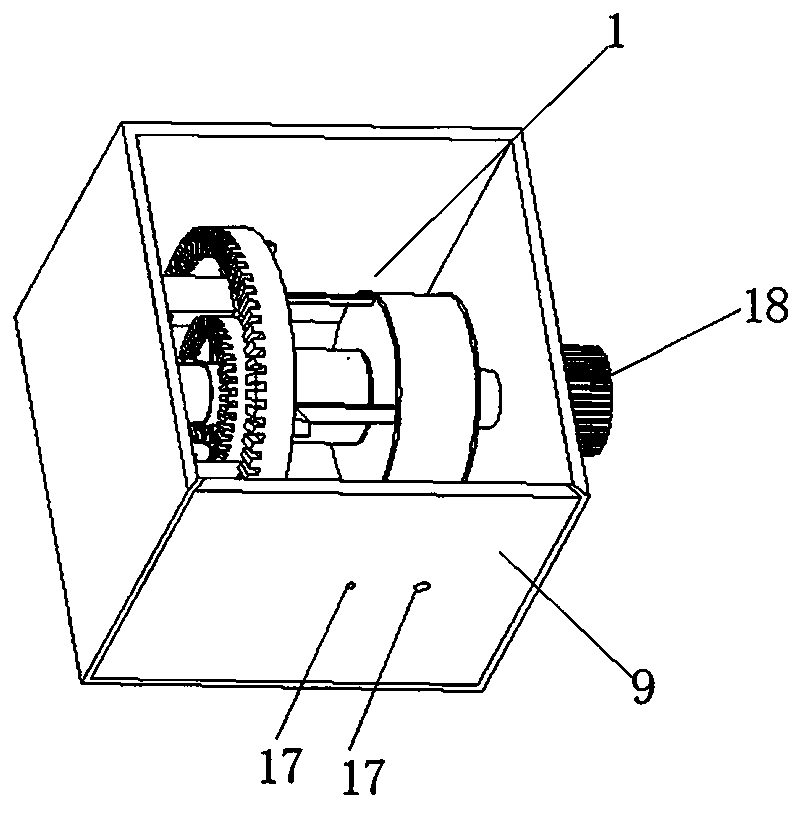

[0025] Such as Figure 1-5 Shown: a high-strength air-jet vortex spinning yarn processing equipment, including a yarn output device 1, a sliver 2, an air-jet vortex chamber 3, rollers, and a heat roll 6. Among them, there are two pairs of rollers, which are respectively the traction roller 4 and the output roller 5. The low-melting point fiber 7 and the ordinary fiber 8 are passed through the yarn output device 1 respectively. Air-jet vortex chamber 3, traction roller 4, heat roller 6, output roller 5 are wound to complete the bobbin.

[0026] The air jet vortex chamber 3 is equipped with air compression equipment, which uses compressed air to form a high-speed rotating airflow field inside the vortex chamber, separates, condenses, and strips the single fibers after drafting, and twists the free ends of the fibers into yarn. The bobbin winding equipment is no ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com