High-strength heat-resisting wrought magnesium alloy and preparation method thereof

A heat-resistant deformation, magnesium alloy technology, applied in the field of non-ferrous metal materials and its processing, can solve the problems of poor high temperature mechanical properties of magnesium alloys, achieve good thermal stability, improve strength and heat resistance, and improve high temperature stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The preparation method of the high-strength heat-resistant deformation magnesium alloy of the present invention, the steps are as follows:

[0048] Step 1, melting magnesium source, zinc source, gadolinium source, ytterbium source and zirconium source to obtain alloy liquid;

[0049] Step 2, cooling the alloy liquid and pouring it into a mold to obtain a casting;

[0050] Step 3, extruding the casting to obtain a high-strength heat-resistant deformable magnesium alloy.

[0051] In the present invention, the types and sources of magnesium sources, zinc sources, gadolinium sources, ytterbium sources and zirconium sources are not particularly limited, and magnesium sources, zinc sources, gadolinium sources, ytterbium sources and zirconium sources well known to those skilled in the art can be used. Usually, the source of magnesium is magnesium ingots, preferably pure magnesium ingots containing more than 99.9 wt% of magnesium; the source of zinc is zinc ingots, preferably ...

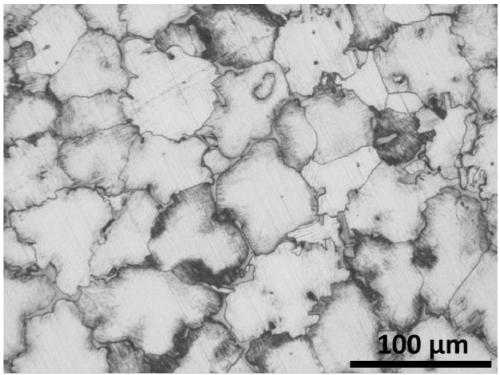

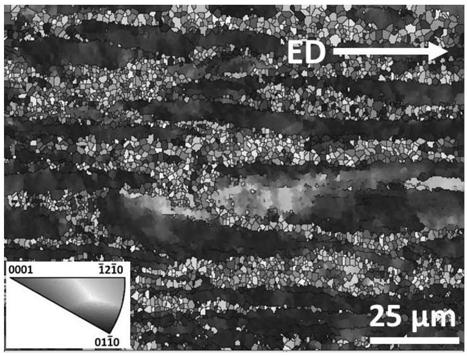

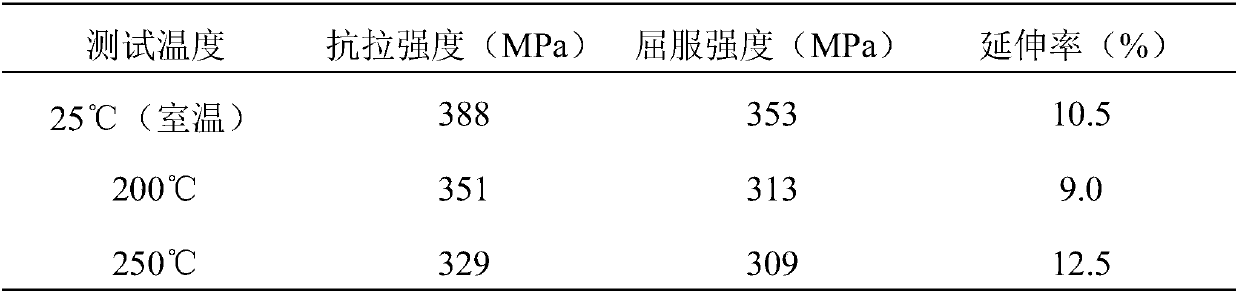

Embodiment 1

[0082] The high-strength heat-resistant deformation magnesium alloy has the following components: Gd 8.0wt%, Yb 1.0wt%, Zn 1.0wt%, Zr 0.5wt%, and the balance is Mg and unavoidable impurity elements.

[0083] The preparation of the above-mentioned high-strength heat-resistant deformation magnesium alloy:

[0084] Step 1, magnesium ingot, zinc ingot, gadolinium source (magnesium-gadolinium master alloy ingot containing 20% gadolinium), ytterbium source (magnesium-ytterbium master alloy ingot containing 20% ytterbium) and zirconium source (magnesium-zirconium master alloy ingot containing 30% zirconium) Intermediate alloy ingot) to remove the oxide layer, prepare materials according to the ratio, and then preheat to 250 ° C.

[0085] Step 2. When the crucible is heated to 550°C, add magnesium ingots under the condition of feeding protective gas. After the magnesium ingots are melted, raise the temperature to 730°C, add zinc ingots, gadolinium sources and ytterbium sources, an...

Embodiment 2

[0093] High-strength heat-resistant deformation magnesium alloy, the composition is: Gd 8.5wt%, Yb 2wt%, Zn 1.2wt%, Zr 0.5wt%, the balance is Mg and unavoidable impurity elements.

[0094] Preparation of high-strength heat-resistant deformation magnesium alloy:

[0095] Step 1, magnesium ingot, zinc ingot, gadolinium source (magnesium-gadolinium master alloy ingot containing 20% gadolinium), ytterbium source (magnesium-ytterbium master alloy ingot containing 20% ytterbium) and zirconium source (magnesium-zirconium master alloy ingot containing 30% zirconium) Intermediate alloy ingot) to remove the oxide layer, prepare materials according to the ratio, and then preheat to 250 ° C.

[0096] Step 2. When the crucible is heated to 550°C, add magnesium ingots under the condition of feeding protective gas, wait for the magnesium ingots to melt, raise the temperature to 720°C, add zinc ingots, gadolinium sources and ytterbium sources, and after they melt, skim Remove scum on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com