Artificial flora cellulose biotransformation method

A technology of cellulose and composite flora, applied in the biological field, can solve problems such as low conversion efficiency, hidden dangers of biological safety, and strict requirements for sterility in the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

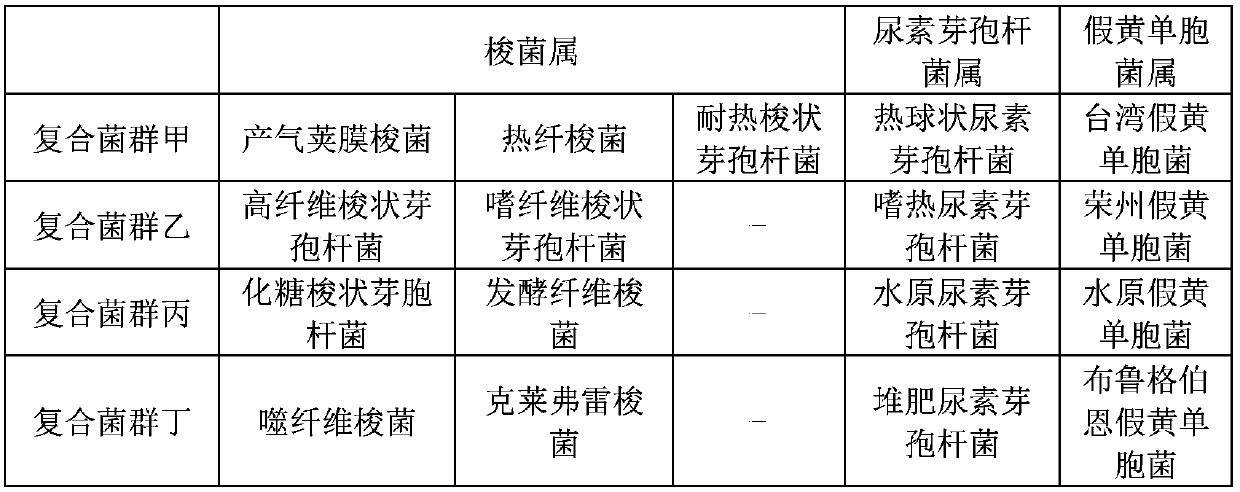

[0076] Embodiment 1, the preparation of composite flora

[0077] During the long-term selection of natural flora in nature, a harmonious symbiotic relationship has been formed, and through the complementation of metabolic pathways, a more efficient synergistic metabolic system for cellulose conversion has been established. Through the research and understanding of these symbiotic relationships and synergistic metabolic mechanisms, it is easier to establish a simplified flora system with stable flora structure and better fermentation performance. The inventors of the present invention have gone through a lot of experiments, based on the research on the mechanism of efficient synergistic conversion of cellulose between strains and the molecular mechanism of strain symbiosis in the natural flora that converts cellulose into biofuels reported in the literature, screened the strains and carried out artificial recombination, and obtained A complex bacterial flora that can efficientl...

Embodiment 2

[0100] Embodiment 2, the stability detection of composite flora

[0101] 1. Stability detection of complex flora A

[0102] 1. Inoculate the composite flora A prepared in Example 1 into 90 mL of restricted medium 1 to obtain a mixed solution; in the mixed solution, the content of Clostridium perfringens is 4 × 10 5 cfu / mL, the content of Clostridium thermocellum was 16×10 5 cfu / mL, the content of thermotolerant Clostridium is 42×10 5 cfu / mL, the content of Bacillus thermosphaeroids is 29×10 5 cfu / mL, the content of Pseudoxanthomonas in Taiwan, China is 9×10 5 cfu / mL.

[0103] 2. Take the mixed solution obtained in step 1, and culture it at 55° C. for 5 days to obtain the first-generation fermentation solution. Inoculate 10 mL of the first-generation fermentation broth into 90 mL of restricted medium 1 and culture at 55°C for 5 days to obtain the second-generation fermentation broth. Inoculate 10 mL of the second-generation fermentation broth into 90 mL of restricted medi...

Embodiment 3

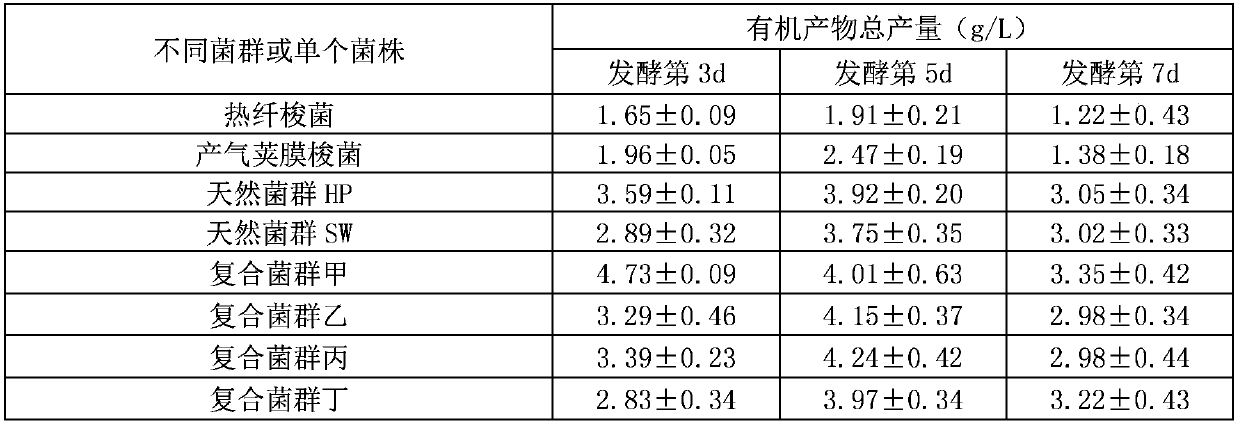

[0136] Embodiment 3, the mensuration of the total output of organic product produced by complex flora fermentation

[0137] 1. Inoculate the composite flora A prepared in Example 1 into 90mL restrictive medium 1 to obtain a mixed solution; in the mixed solution, the total content of bacteria is 1×10 7 cfu / mL, the content of Clostridium perfringens is 4×10 5 cfu / mL, the content of Clostridium thermocellum was 16×10 5 cfu / mL, the content of thermotolerant Clostridium is 42×10 5 cfu / mL, the content of Bacillus thermospheroidus is 29×10 5 cfu / mL, the content of Pseudoxanthomonas in Taiwan, China is 9×10 5 cfu / mL. The mixture was cultured at 55° C. for 3 d or 5 d to obtain a fermented liquid.

[0138] 2. Inoculate Clostridium thermocellum into 90 mL of restricted medium 1 to obtain a mixture; in the mixture, the content of Clostridium thermocellum is 1×10 7 cfu / mL. The mixture was cultured at 55° C. for 3 d or 5 d to obtain a fermented liquid.

[0139] 3. Inoculate Clostrid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com