A food-grade vacuum pump oil composition mainly composed of synthetic oil

A vacuum pump oil, food-grade technology, used in lubricating compositions, petroleum industry, etc., to achieve the effects of low extreme pressure, high viscosity index, good extreme pressure and anti-wear properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0060] The components of the synthetic oil-based food-grade vacuum pump oil composition in Examples 1-3 are shown in Table 1.

[0061] Each component content of table 1 embodiment 1

[0062] raw material Example 1 (%) DURASYN 166 30.5 DURASYN 170 60 DURASYN 174I margin IRGANOX L06 0.5 IRGANOX L101 0.5 AmorCal TM 400FG

2.0 VANLUBE 9123 0.5 VANLUBE 7723 0.5 SARKOSYL O 0.05 Foam Ban 159 0.1

[0063] Table 2 embodiment 2 each component content

[0064] raw material Example 2 (%) DURASYN 166 margin DURASYN 170 90 DURASYN 174I 5 IRGANOX L06 0.5 IRGANOX L101 0.5 AmorCal TM 400FG

2.0 VANLUBE 9123 0.5 VANLUBE 7723 0.5 SARKOSYL O 0.05 Foam Ban 159 0.1

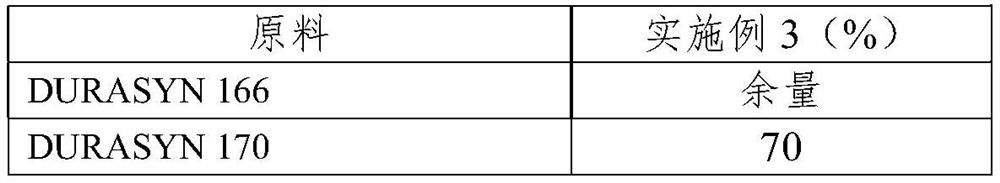

[0065] Table 3 embodiment 3 each component content

[0066]

[0067]

Embodiment 4

[0069] This example provides the preparation method of the composition described in Examples 1-3, specifically as follows: first heat the food-grade base oil to 60°C, then add food-grade high-temperature antioxidant and stir until uniform and transparent, and then add food-grade High-temperature detergent and dispersant, food-grade extreme pressure anti-wear agent, food-grade anti-corrosion inhibitor, food-grade rust inhibitor are stirred evenly, and finally food-grade antifoaming agent is added according to the ratio and stirred evenly.

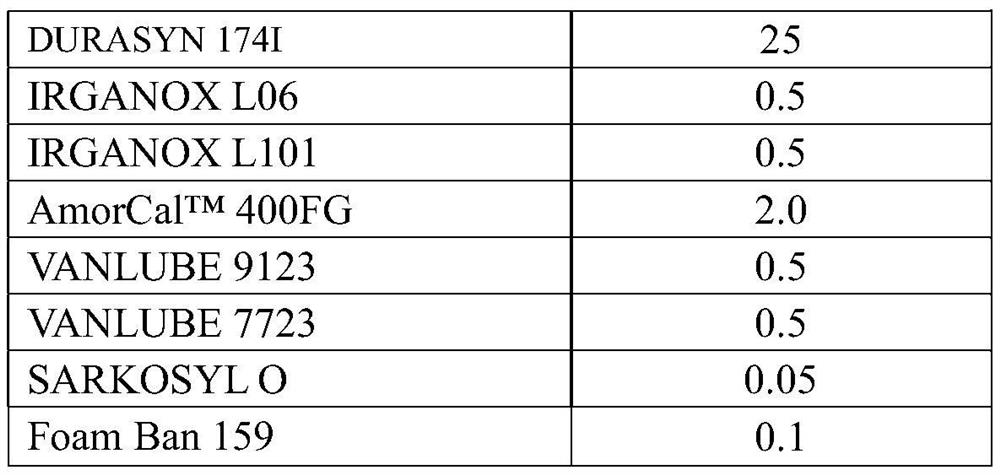

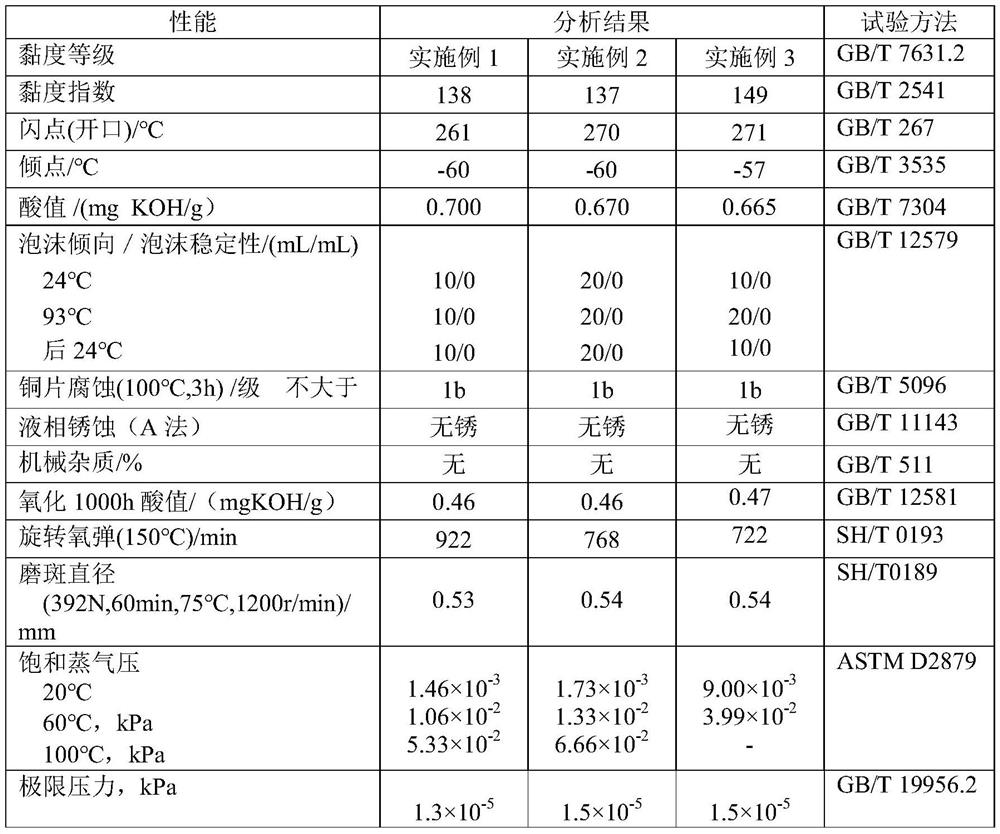

[0070] Embodiment 1-3 is carried out each performance evaluation, and result is as follows:

[0071] Table 4 Physical and chemical analysis of food grade vacuum pump oil

[0072]

[0073]

[0074] The above data show that a food-grade vacuum pump oil product based on synthetic oil of the present invention has excellent extreme pressure and anti-wear properties on the basis of meeting the requirements of NSF H1 food-grade lubricating oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com