Liquid crystal composition, liquid crystal display element and liquid crystal display

A technology of liquid crystal composition and liquid crystal compound, which is applied in the direction of liquid crystal materials, chemical instruments and methods, and can solve the problems of high energy consumption and light waste of liquid crystal panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

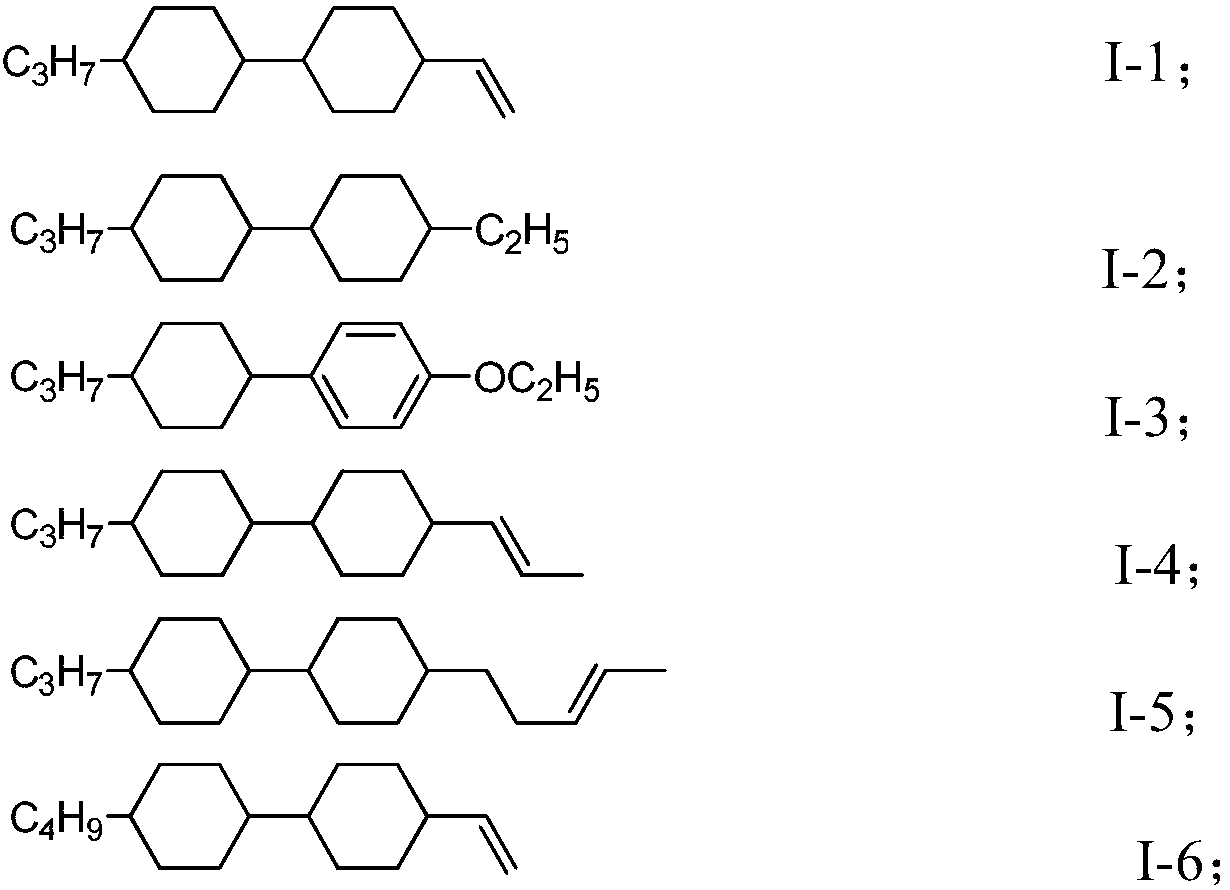

Method used

Image

Examples

Embodiment 1

[0106]

[0107]

[0108] The liquid crystal composition provided by Comparative Example 1-2 and the liquid crystal composition provided by Example 1 were respectively poured into the test box for testing: the transmittance of the liquid crystal composition of Comparative Example 1 was 5.4%, and the transmittance of the liquid crystal composition of Comparative Example 2 was 5.4%. The transmittance is 5.3%, and the transmittance of the liquid crystal composition of Example 1 is 6%, which is 11% and 13% higher than that of the liquid crystal compositions of Comparative Example 1 and Comparative Example 2, respectively. And other aspects of performance, such as clearing point, refractive index, dielectric, response time, etc., are not lost, thus obtaining a liquid crystal product with fast response, high transmittance, and good stability.

Embodiment 2

[0110]

[0111]

[0112] The liquid crystal composition provided by Comparative Example 1-2 and the liquid crystal composition provided by Example 2 were respectively poured into the test box for testing: the transmittance of the liquid crystal composition of Comparative Example 1 was 5.4%, and the transmittance of the liquid crystal composition of Comparative Example 2 was 5.4%. The transmittance is 5.3%, and the transmittance of the liquid crystal composition of Example 2 is 6.1%, which is 13% and 15% higher than that of the liquid crystal compositions of Comparative Example 1 and Comparative Example 2, respectively. Moreover, the liquid crystal composition of Example 2 has a relatively large refractive index, is suitable for display applications such as low cell thickness, and is conducive to realizing performances such as wide viewing angle, high contrast ratio, and high-quality dynamic picture playback.

Embodiment 3

[0114]

[0115]

[0116] The liquid crystal composition provided by Comparative Example 1-2 and the liquid crystal composition provided by Example 3 were respectively poured into the test box for testing: the transmittance of the liquid crystal composition of Comparative Example 1 was 5.4%, and the transmittance of the liquid crystal composition of Comparative Example 2 was 5.4%. The transmittance is 5.3%, and the transmittance of the liquid crystal composition of Example 3 is 6.2%, which is 15% and 17% higher than that of the liquid crystal compositions of Comparative Example 1 and Comparative Example 2, respectively. And the liquid crystal composition of Example 3 has a lower rotational viscosity, and is suitable for high transmittance and fast response liquid crystal displays.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com