Preparation method and apparatus of nitrogen oxides

A technology for preparing equipment for nitrogen oxides, applied in the direction of nitrogen oxides/oxyacids, nitrogen dioxide, etc., can solve serious problems, corrosion of equipment and pipelines, difficult long-term stable operation, etc., to improve the oxidation effect, The effect of avoiding corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

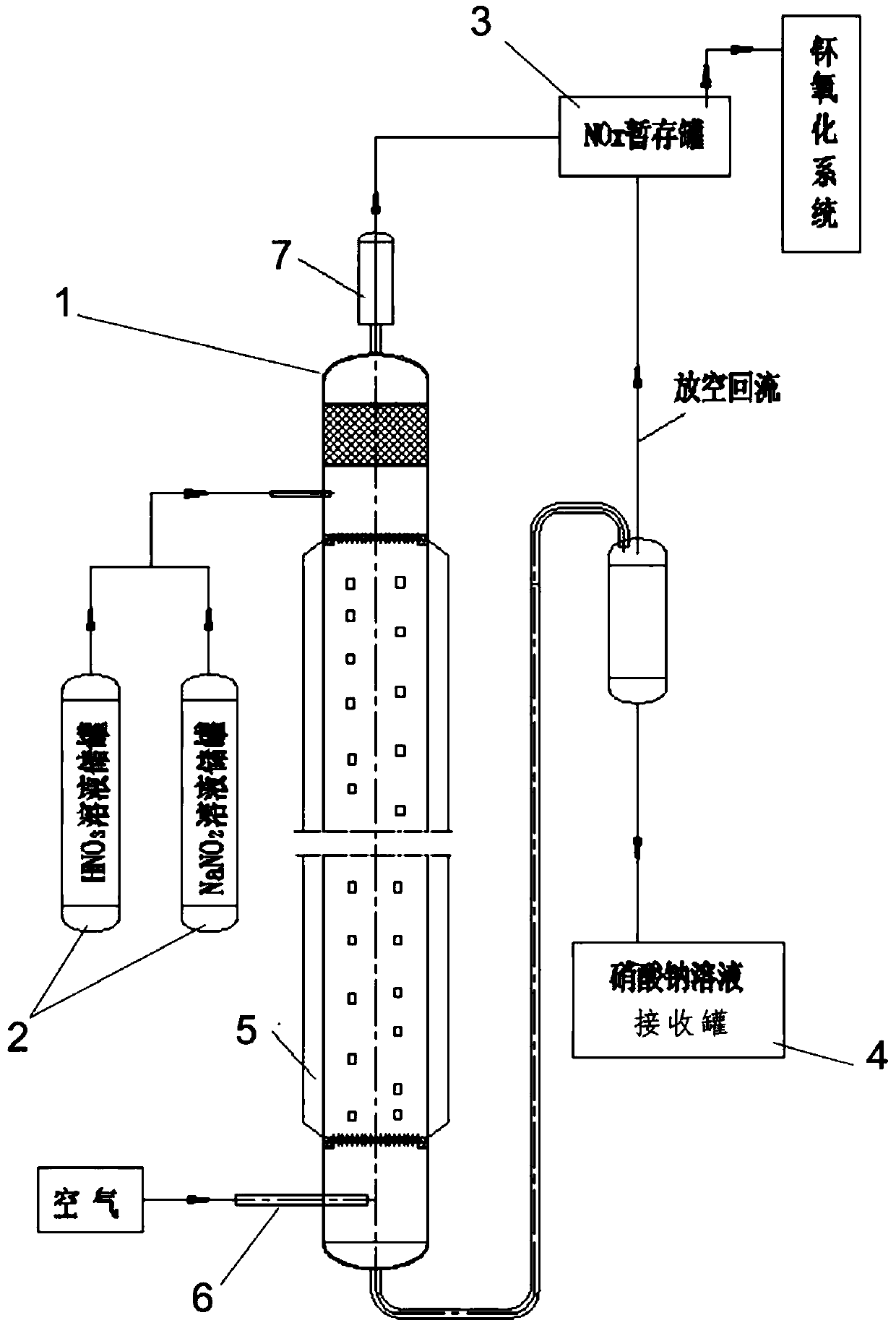

[0031] like figure 1 The size parameters of the nitrogen oxide preparation device shown are as follows: the total height of the packing column is 1900mm, the diameter is 60mm, the packing is made of theta ring (stainless steel), Φ5*5mm, and the upper part of the packing column is kept in a circulating water jacket.

[0032] Nitrogen oxide preparation experiments were carried out based on the established nitrogen oxide preparation device, and the generated nitrogen oxides were absorbed and treated with hydrazine nitrate-hydroxylamine solution.

[0033] Reaction feed liquid: nitric acid concentration 10mo / L, sodium nitrite concentration 4mol / L.

[0034] Operating process conditions:

[0035] The flow rate of nitric acid liquid is 2.5L / h, the flow rate of sodium nitrite solution is 5L / h, the air flow rate at the bottom of the packed column is 650L / h, and the temperature of heat preservation circulating water is 80°C; the nitrogen oxides produced are made of hydrazine nitrate-hyd...

Embodiment 2

[0037] like figure 1 The size parameters of the nitrogen oxide preparation device shown are as follows: the total height of the packing column is 1900mm, the diameter is 60mm, the packing is made of theta ring (stainless steel), Φ5*5mm, and the upper part of the packing column is kept in a circulating water jacket.

[0038] Nitrogen oxide preparation experiments were carried out based on the established nitrogen oxide preparation device, and the generated nitrogen oxides were absorbed and treated with hydrazine nitrate-hydroxylamine solution.

[0039] Reaction feed liquid: nitric acid concentration 10mo / L, sodium nitrite concentration 4mol / L.

[0040] Operating process conditions:

[0041] The flow rate of nitric acid feed solution is 2L / h, the flow rate of sodium nitrite solution is 4L / h, the air flow rate at the bottom of the packed column is 500L / h, and the temperature of heat preservation circulating water is 75°C; the nitrogen oxides produced use hydrazine nitrate-hydrox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com