Caprolactam pipeline cleaning system and method

A technology of caprolactam and cleaning system, applied in the field of cleaning system of caprolactam pipeline, can solve the problems of damage to pipeline and polymerization reaction tower, difficult pressure control, pollution of pipeline raw materials, etc., so as to reduce product rejection rate, avoid potential safety hazards, The effect of solving security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

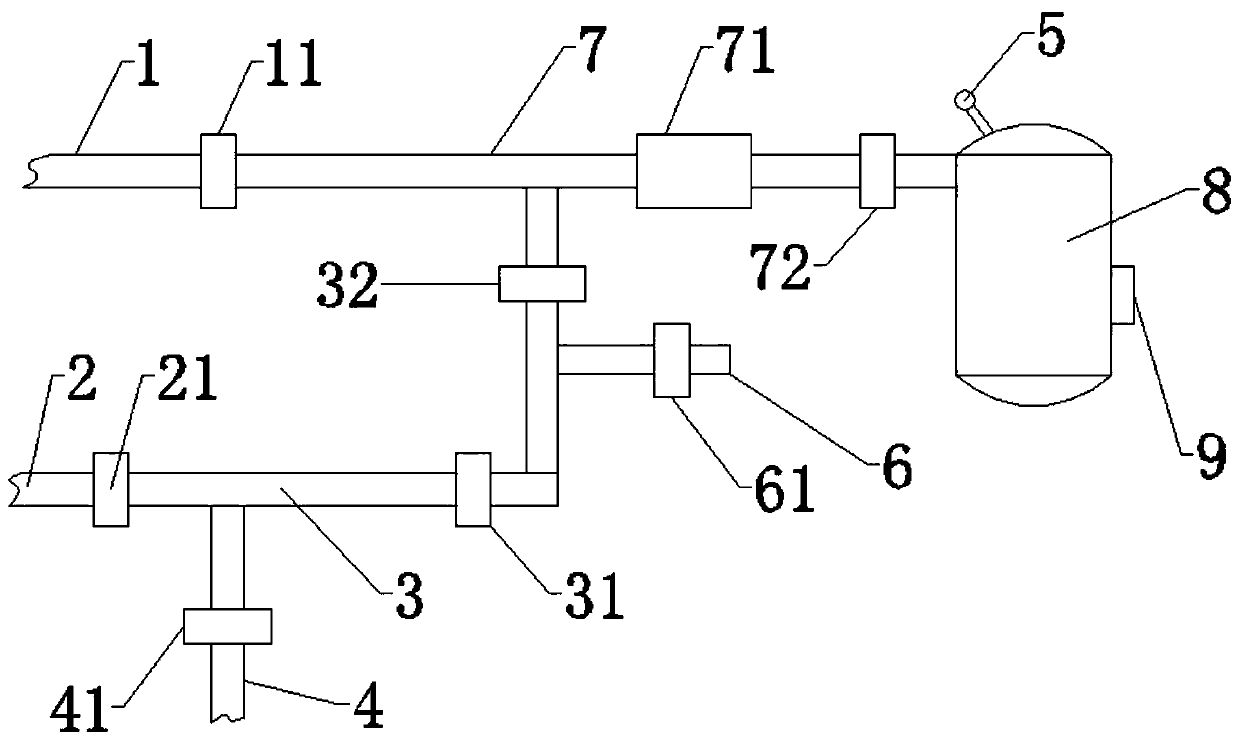

[0027] see figure 1 As shown, the present invention provides a technical solution: a cleaning system for a caprolactam pipeline. The caprolactam pipeline includes a caprolactam feeding pipeline 1, a production pipeline 7, a heater 71 and a polymerization tower 8. The cleaning system includes a cleaning pipeline 3. The outlet of the cleaning pipeline 3 is connected to the production pipeline 7, and the inlet of the cleaning pipeline 3 is respectively connected with the steam inlet pipe 2 which can be opened and closed and the inert gas inlet pipe 4 which can be controlled to be opened and closed. The cleaning pipeline 3 An overpressure protection valve 31 is set on the above, and a pressure sensor 5 is also set in the polymerization reaction tower 8, and the pressure sensor 5 and the overpressure protection valve 31 are respectively electrically connected to the controller 9 to automatically control the pressure threshold and protect the polymerization The safety of the reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com