Method for preparing lithium battery positive electrode material based on in-situ composite and recombination

A positive electrode material and in-situ composite technology, which is applied in the direction of battery electrodes, lithium batteries, positive electrodes, etc., to achieve the effects of uniform and dense particle size distribution, improved conductivity, and stable voltage window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

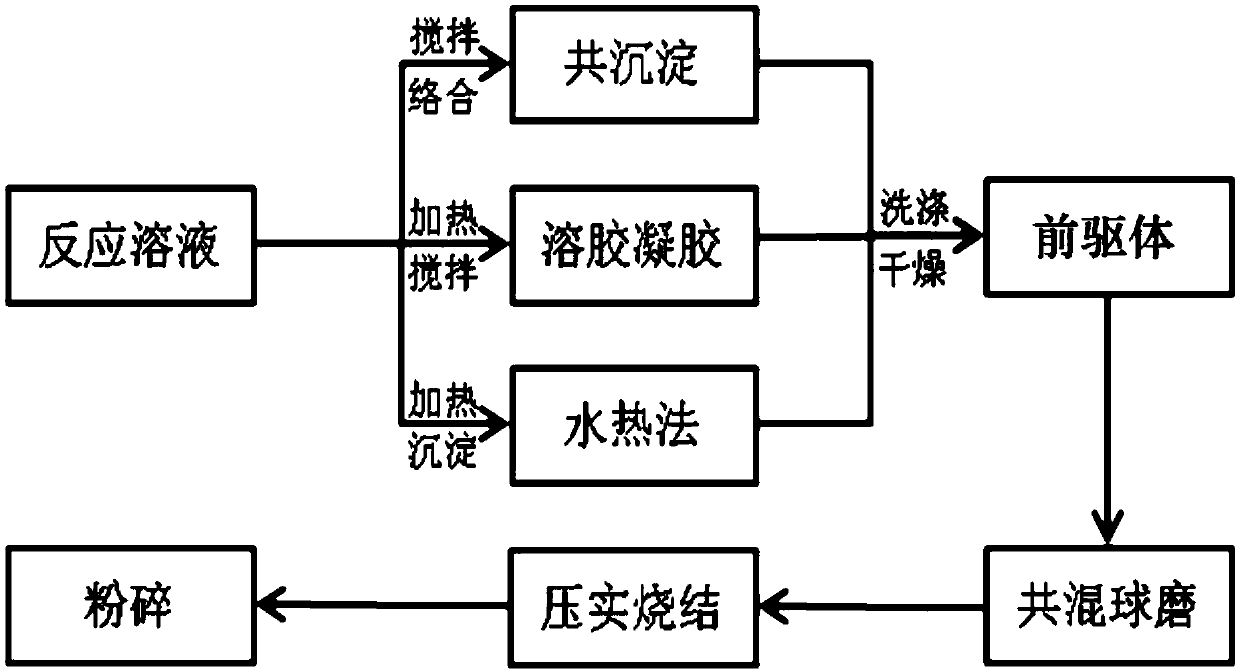

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing lithium battery cathode materials based on in-situ compounding and recombination, comprising the following steps:

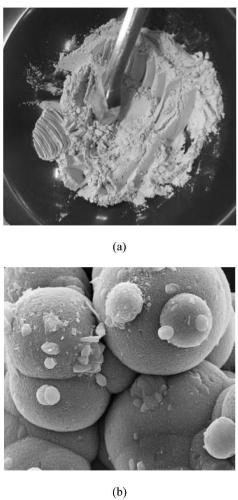

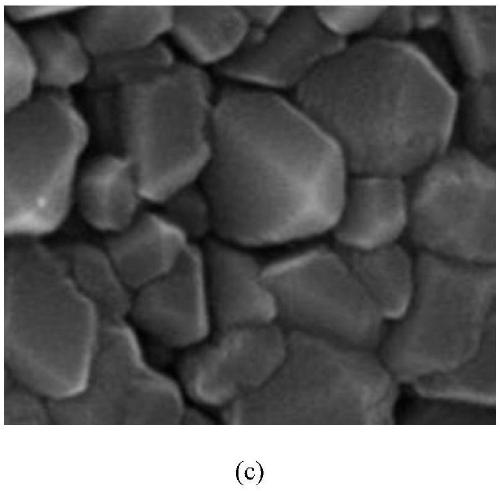

[0031] (1) Mn-Co-Ni ternary composite lithium-rich manganese-based cathode material was prepared by co-precipitation method, and the selected raw material was MnSO 4 、CoSO 4 、NiSO 4 , the MnSO 4 、CoSO 4 and NiSO 4 The molar ratio is 4.2:1:1; and then stirred at a constant temperature in an oil bath at 80°C for 4 hours to form figure 2 The pink precipitate shown in (a); the washed and dried precursor was sintered at 850 °C for 24 hours in an air atmosphere, and finally a pure-phase LMR material was obtained. The microstructure of the sintered product is as follows figure 2 as shown in (b);

[0032] (2) Combine the pure-phase LMR prepared in step (1) with LiMnO 2 , Li 2S. Super-P is mixed by high-energy liquid phase ball milling, and acetone is selected as the medium. Under the condition of 600r / min, ball milling is carried o...

Embodiment 2

[0040] A method for preparing lithium battery cathode materials based on in-situ compounding and recombination, comprising the following steps:

[0041] (1) Mn-Co binary composite lithium-rich manganese-based cathode material was prepared by hydrothermal method, and the selected raw material was MnSO 4 、CoSO 4 , the MnSO 4 、CoSO 4 The molar ratio of the solution is 4:1, stirred at room temperature until it is completely dissolved, and the reaction solution is prepared; then the reaction solution is transferred to a 100ml reaction kettle liner, and placed in a 150°C oven at a constant temperature for 24 hours , to obtain a pink precipitate; the washed and dried precursor was first sintered at 400°C for 4 hours in an air atmosphere, and then heated to 800°C for 20 hours to obtain a pure-phase LMR material;

[0042] (2) The pure phase LMR and MnO obtained in step (1) 2 , MnCl 2 , Carbon black were pressed separately to make sputtering targets;

[0043] (3) Put the sputterin...

Embodiment 3

[0045] A method for preparing lithium battery cathode materials based on in-situ compounding and recombination, comprising the following steps:

[0046] (1) Mn-Ti binary composite lithium-rich manganese-based cathode material was prepared by co-precipitation method, and the selected raw material was MnSO 4 、Ti(SO4) 2 9H 2 O, the MnSO 4 、Ti(SO4) 2 9H 2 The molar ratio of O was 5:2; then stirred at a constant temperature in an oil bath at 70°C for 3 hours; the washed and dried precursor was sintered at 850°C for 24 hours in an air atmosphere, and finally a pure-phase LMR material was obtained;

[0047] (2) Combine the pure-phase LMR prepared in step (1) with MnO 2 , Li 2 S. The asphalt is mixed by high-energy liquid phase ball milling, and acetone is selected as the medium. Under the condition of 700r / min, the ball milling is carried out for 20 hours, the mixture obtained after ball milling is collected, and the primary target is prepared by a tablet press;

[0048] (3) P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com