Method to increase the effect of volume fracturing in complex oil and gas layer fracture network

A technology for volume fracturing and oil and gas formation, which is applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc. It can solve the problem of increasing the volume fracturing effect of the fracture network of complex oil and gas formations, rapid decline of pressure and production after fracturing, and increasing production. In order to improve the fracturing stimulation effect and the degree of reservoir production, improve the stable production period after fracturing, and maximize the stimulation effect of fracture network volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

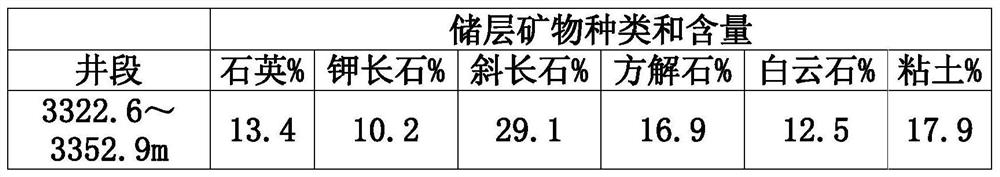

[0027] Embodiment 1, the method for increasing the volume fracturing effect of the fracture network in complex oil and gas layers is characterized in that it is carried out according to the following steps: the first step, the planar fracture network is reformed, and the planar fractures of the fractured reservoir near the perforation point are sequentially Alternate injection of non-acid slick water and acid slick water; second step, formation of viscosified branch joints, viscosification of non-acid slick water and acid slick water and addition of support diversion agent; third step, formation of artificial cracks, injection of water base Fracturing fluid, forming artificial fractures with a fracture length of not less than 100 meters on both sides of the perforation point; the fourth step, three-dimensional fracture network reconstruction, alternately injecting non-acidic slick water and acidic slick water, and performing fracture network on the artificial fracture wall surfa...

Embodiment 2

[0029] Embodiment 2, as the optimization of above-mentioned embodiment, acid slippery water comprises the hydrochloric acid of 5 parts to 25 parts, the hydrofluoric acid of 0 part to 8 parts, the corrosion inhibitor of 1 part to 2 parts, the lemon of 0.5 part to 1 part Acid, 0.5 to 1 part of drainage aid, 0.5 to 2.5 parts of drag reducing agent, and the acidic slippery water needs to meet the corrosion inhibition rate ≤ 0.5g / m2 h, compared with clear water, the drag reduction rate ≥ 40% , The viscosity of the acid solution is ≤10mPa·s, the optimum viscosity is 2mPa·s to 8mPa·s, and the surface tension is ≤25mN / m. The acidic slick water of the present invention has a good corrosion inhibition effect, and in the case of the optimal dosage, the corrosion inhibition rate is ≤0.5g / cm 2 .h; to minimize the damage caused by acid corrosion of the oil casing.

Embodiment 3

[0030] Embodiment 3, as an optimization of the above-mentioned embodiment 2, the corrosion inhibitor in acidic slippery water is an imidazoline type corrosion inhibitor; or / and, the drainage aid is a fluorocarbon type drainage aid; or / and, the drag reducing agent It is an acid-resistant drag-reducing agent, which is formed by copolymerization of acrylamide monomer and other acid-resistant and salt-resistant monomers, with a molecular weight between 6 million and 10 million. The imidazoline type corrosion inhibitor is preferably KML-HS acidification corrosion inhibitor or ALS-2 acidification corrosion inhibitor, KML-HS acidification corrosion inhibitor is produced by Karamay Kemeili Chemical Co., Ltd., ALS-2 acidification corrosion inhibitor is produced by Produced by Shandong Anqiu Plasticizer Factory; the drainage aid is preferably KML-ZP acidification drainage aid or YL-103 acidification drainage aid, KML-ZP acidification drainage aid is produced by Karamay Kemeili Chemical C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com