Crack forming method for multiple scales of cracks

A multi-scale, fracture-making technology, applied in the direction of earth drilling, production fluid, wellbore/well components, etc., can solve the problems of low fracturing success rate of complex fractures, increased fracture complexity and fracturing construction success rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

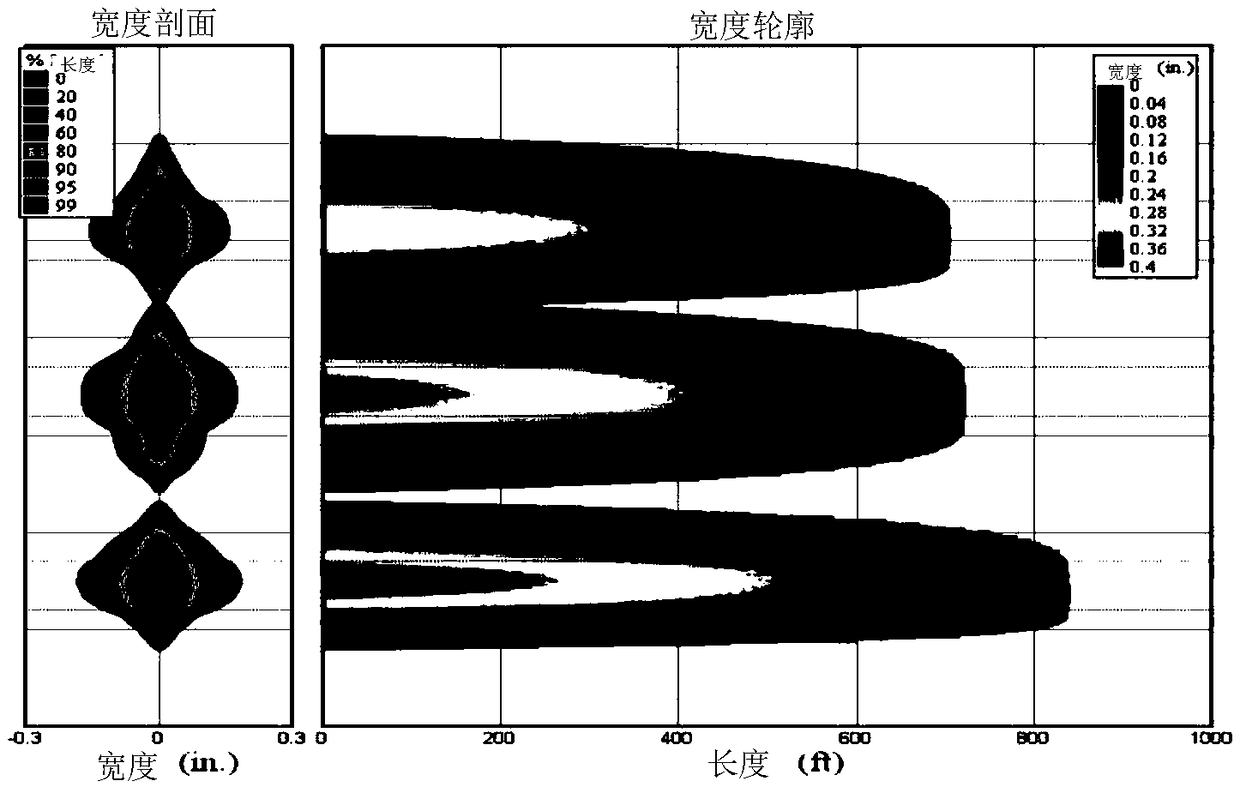

Image

Examples

example 1

[0058] Example 1: Take a certain tight oil well X in China as an example to further illustrate the present invention:

[0059] (1) Precise evaluation of reservoirs before fracturing

[0060] Based on the results of the constant-speed mercury injection experiment, the microscopic pore-throat structure parameters of the core were obtained, and the basic parameters such as rock mechanical parameters and in-situ stress characteristics were obtained by using acoustic emission technology and dipole acoustic logging technology.

[0061] (2) Preparation of artificial rock samples

[0062] On the basis of (1), use natural quartz sand and cement with different particle sizes (100 mesh, 20 / 40 mesh, etc.) and mix them in different proportions to simulate the throat radius after classification in (1) to prepare a 300mm square large rock samples for use.

[0063] (3) Physical simulation experiment of core fracture rupture and expansion with different pore throat structure parameters

[0...

example 2

[0077] Example two: Take a certain tight gas well Y in China as an example to further illustrate the present invention:

[0078] (1) Precise evaluation of reservoirs before fracturing

[0079] According to the results of constant-speed mercury injection experiments, the microscopic pore-throat structure parameters of the core were obtained, and the basic parameters such as rock mechanical parameters and in-situ stress characteristics were obtained by using acoustic emission technology and dipole acoustic logging technology.

[0080] (2) Preparation of artificial rock samples

[0081] On the basis of (1), use natural quartz sand and cement with different particle sizes (100 mesh, 20 / 40 mesh, etc.) and mix them in different proportions to simulate the throat radius after classification in (1) to prepare a 300mm square large rock samples for use.

[0082] (3) Physical simulation experiment of core fracture rupture and expansion with different pore throat structure parameters

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com