Preparing methods of carbon quantum dots and phosphorescence composite material of carbon quantum dots

A technology of carbon quantum dots and composite materials, which is applied in the field of preparation of luminescent carbon nanomaterials, can solve the problems of unsatisfactory fluorescence quantum efficiency of carbon quantum dots, insufficient phosphorescence performance of phosphorescent composite materials, complicated preparation conditions and synthesis process, etc., and achieves excellent results. Room temperature phosphorescence performance, strong design, high fluorescence quantum efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

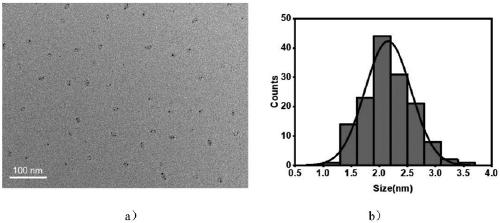

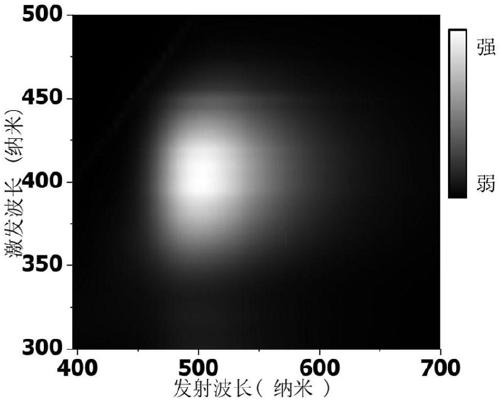

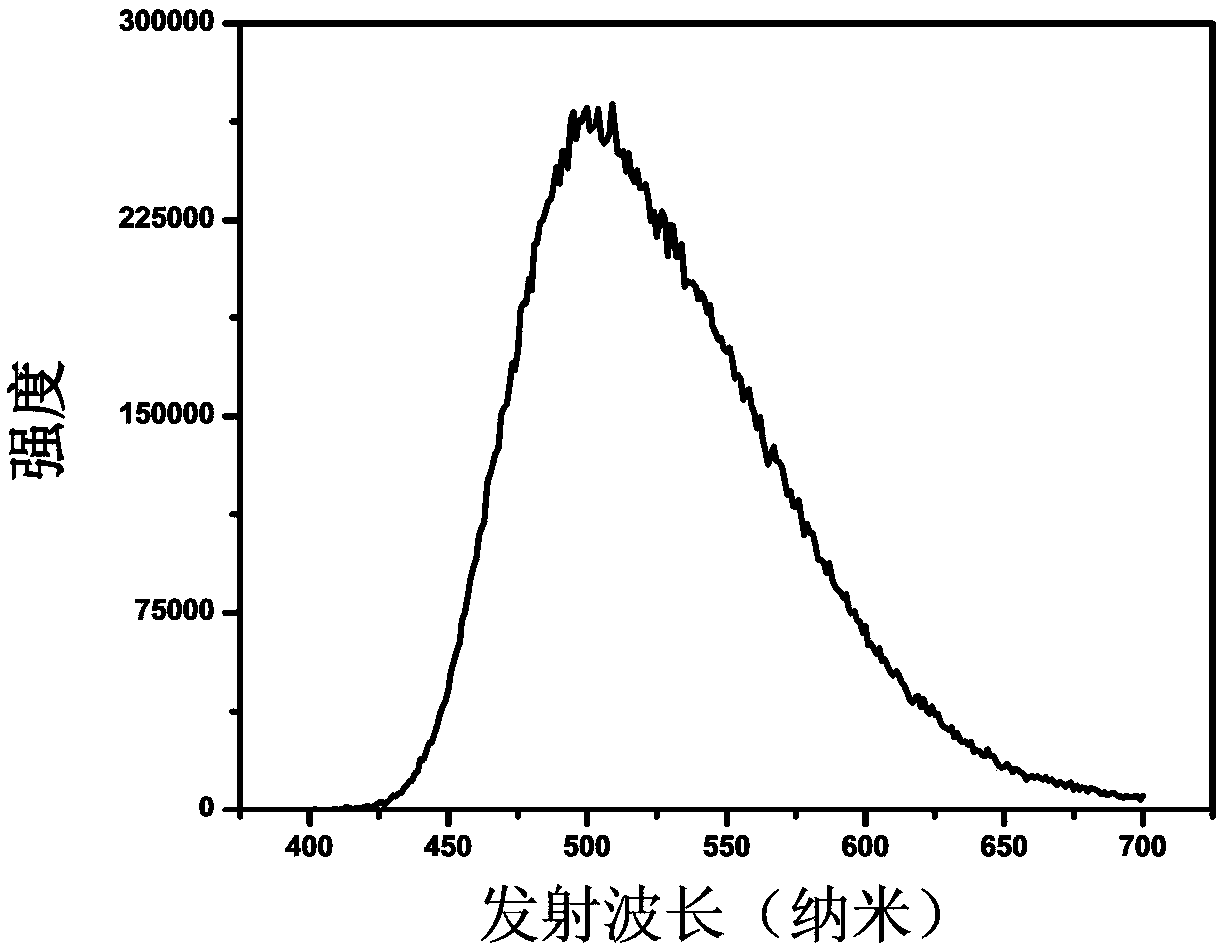

[0032] (1) Preparation of carbon quantum dots

[0033] Tetrahydrofuran heat treatment: take 180ml of tetrahydrofuran in a polytetrafluoroethylene hydrothermal kettle, and react at 120°C for 120min.

[0034] Weigh 20 mg of 3,5-diaminobenzoic acid and dissolve it in a mixed solvent of heat-treated tetrahydrofuran and water at a volume ratio of 1:1 to prepare a mixed solution with a monomer concentration of 0.1 mg / mL. Add hydrochloric acid with a volume fraction of 0.01%, and mix well. The mixed solution was stirred at room temperature for 72 h. The above solution was then concentrated and excess impurities and unreacted starting materials were removed by column chromatography. Finally, solid powder of carbon quantum dots was obtained by freeze-drying.

[0035] (2) Preparation of phosphorescent composite materials

[0036] The prepared carbon quantum dots are added into the polyacrylic acid aqueous solution at a mass fraction of 0.02%, and the obtained product can be freeze-d...

Embodiment 2

[0039] (1) Preparation of carbon quantum dots

[0040] Tetrahydrofuran heat treatment: take 180ml tetrahydrofuran in a polytetrafluoroethylene hydrothermal kettle, and react at 130°C for 150min.

[0041] Weigh 20 mg of 3,5-diaminobenzoic acid and dissolve it in heat-treated tetrahydrofuran to prepare a mixed solution with a monomer concentration of 5 mg / mL. Add sulfuric acid with a volume fraction of 0.01%, and mix well. The mixed solution was stirred at room temperature for 24 h. The above solution was then concentrated and excess impurities and unreacted starting materials were removed by column chromatography. Finally, solid powder of carbon quantum dots was obtained by freeze-drying.

[0042] (2) Preparation of phosphorescent composite materials

[0043] The prepared carbon quantum dots are added into an aqueous solution of polyacrylamide at a mass fraction of 0.2%, and the obtained product is dried at 120° C. to obtain a carbon quantum dot-based room-temperature phosp...

Embodiment 3

[0045] (1) Preparation of carbon quantum dots

[0046] Tetrahydrofuran heat treatment: take 180ml of tetrahydrofuran in a polytetrafluoroethylene hydrothermal kettle, and react at 120°C for 120min.

[0047] Weigh 20 mg of 2,4-diaminobenzenesulfonic acid and dissolve it in a mixed solvent of heat-treated tetrahydrofuran and methanol at a volume ratio of 5:1 to prepare a mixed solution with a monomer concentration of 1 mg / mL. Add phosphoric acid with a volume fraction of 0.001%, and mix well. The mixed solution was stirred at room temperature for 96 h. The above solution was then concentrated and excess impurities and unreacted starting materials were removed by column chromatography. Finally, solid powder of carbon quantum dots was obtained by freeze-drying.

[0048](2) Preparation of phosphorescent composite materials

[0049] The prepared carbon quantum dots are added into an aqueous solution of polymaleic acid at a mass fraction of 1%, and the obtained product can be fre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com