Water-based self-luminous marking coating and preparing method thereof

A marking paint, self-luminous technology, used in luminescent paint, antifouling/underwater paint, epoxy resin paint, etc., can solve the problems of peeling, poor temperature difference resistance, easy aging and cracking, etc. Good antioxidant properties, reducing the effect of large temperature difference between day and night

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

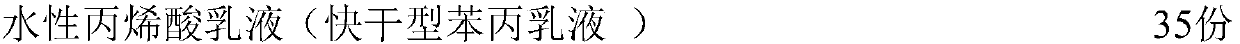

[0051] Water-based paint formulation:

[0052]

[0053]

[0054] The water-based self-illuminating marking paint also includes a water-based epoxy curing agent; the content ratio of the water-based epoxy emulsion to the water-based epoxy curing agent is 55-45:55-45.

[0055] The curing agent is water-based epoxy curing agent GCA02.

[0056] 1) Material preparation: Accurately weigh all the required raw materials according to the formula, and set aside.

[0057] 2) Add the weighed water-based acrylic emulsion, fluorocarbon emulsion, water-based epoxy emulsion, water-based dispersant, film-forming aid, and defoamer into the dispersion tank, and stir at a low speed (200r / min) for 5 minutes, and stir evenly .

[0058] 3) Increase the stirring speed to 400r / min, slowly and evenly add the weighed titanium dioxide and nano fillers, after adding, increase the stirring speed to 1000r / min, stir for 15 minutes, and stir evenly.

[0059] 4) Add the weighed water-based wax emulsio...

Embodiment approach 2

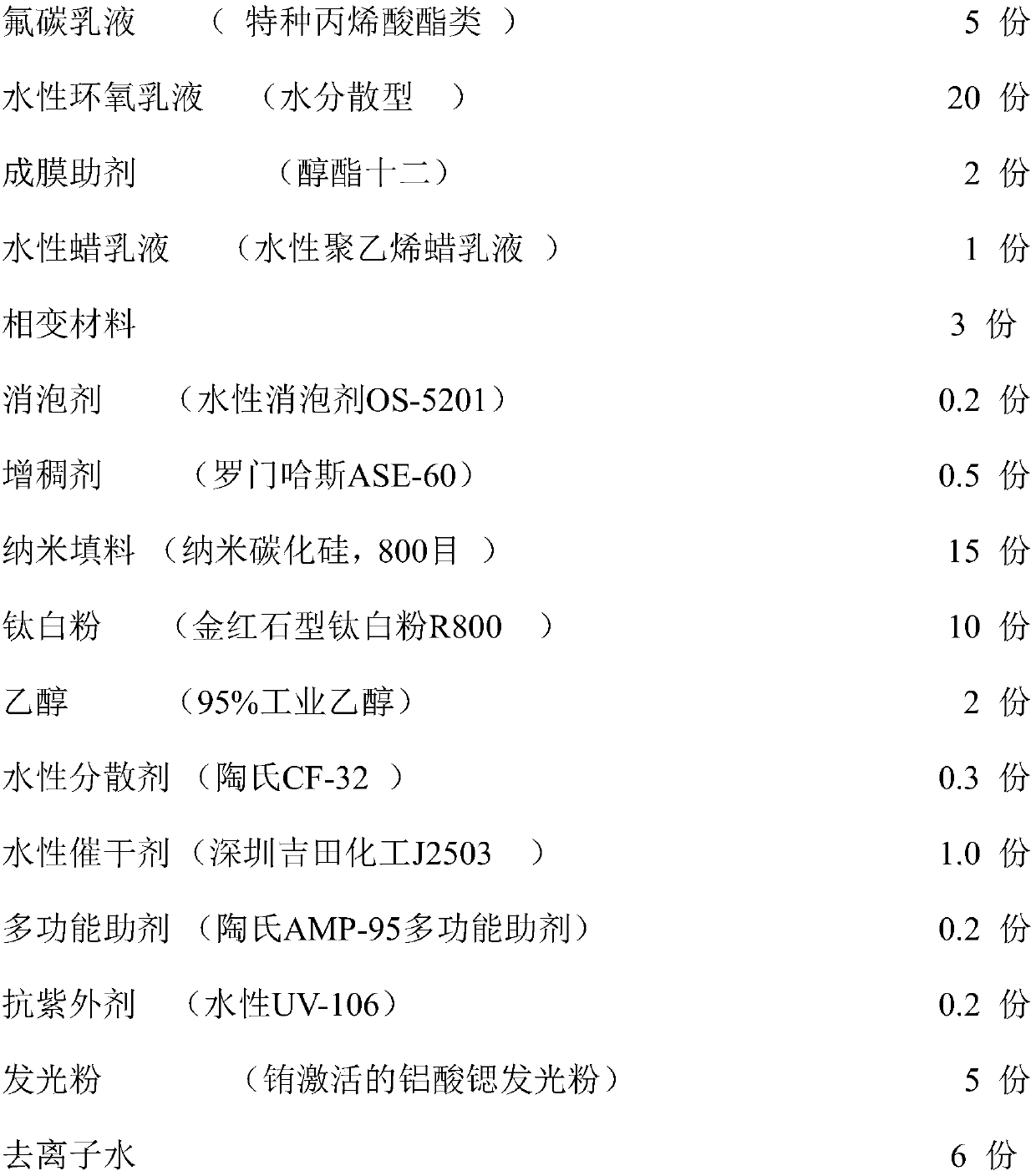

[0063] Water-based paint formulation:

[0064]

[0065]

[0066] 1) 4 parts deionized water

[0067] 2) The water-based self-illuminating marking paint also includes a water-based epoxy curing agent; the content ratio of the water-based epoxy emulsion to the water-based epoxy curing agent is 55-45:55-45.

[0068] 3) The curing agent is water-based epoxy curing agent HTW208.

[0069] 4) Raw material preparation: Accurately weigh the various raw materials required according to the formula, and set them aside.

[0070] 5) Add the weighed water-based acrylic emulsion, fluorocarbon emulsion, water-based epoxy emulsion, water-based dispersant, film-forming aid, and defoamer into the dispersion tank, and stir at a low speed (200r / min) for 5 minutes, and stir evenly .

[0071] 6) Increase the stirring speed to 400r / min, slowly and evenly add the weighed titanium dioxide and nano fillers, after adding, increase the stirring speed to 1000r / min, stir for 15 minutes, and stir eve...

Embodiment approach 3

[0076] Water-based paint formulation:

[0077]

[0078]

[0079] 1) The water-based self-illuminating marking paint also includes a water-based epoxy curing agent; the content ratio of the water-based epoxy emulsion to the water-based epoxy curing agent is 55-45:55-45.

[0080] The curing agent is water-based epoxy curing agent GCA01.

[0081] 2) Material preparation: Accurately weigh the various raw materials required according to the formula, and set them aside.

[0082] 3) Add the weighed water-based acrylic emulsion, fluorocarbon emulsion, water-based epoxy emulsion, water-based dispersant, film-forming aid, and defoamer into the dispersion tank, and stir at a low speed (200r / min) for 5 minutes, and stir evenly .

[0083] 4) Increase the stirring speed to 400r / min, slowly and evenly add the weighed titanium dioxide and nano fillers, after adding, increase the stirring speed to 1000r / min, stir for 15 minutes, and stir evenly.

[0084] 5) Add the weighed water-based...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com