Method for purifying wet-process phosphoric acid by using centrifugal extractor

A centrifugal extractor, wet phosphoric acid technology, applied in separation methods, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of low processing capacity, increased axial mixing, high power consumption, etc., and achieve the effect of phase separation Good, high extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

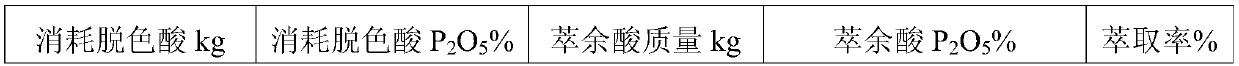

[0053] The pretreatment acid index is as follows:

[0054] raw material name

P 2 o 5 %

CaO%

MgO%

Fe 2 o 3 %

al 2 o 3 %

F%

SO4 2- %

proportion

pretreatment acid

39.02

0.074

1.76

0.32

0.2

0.083

3.62

1.47

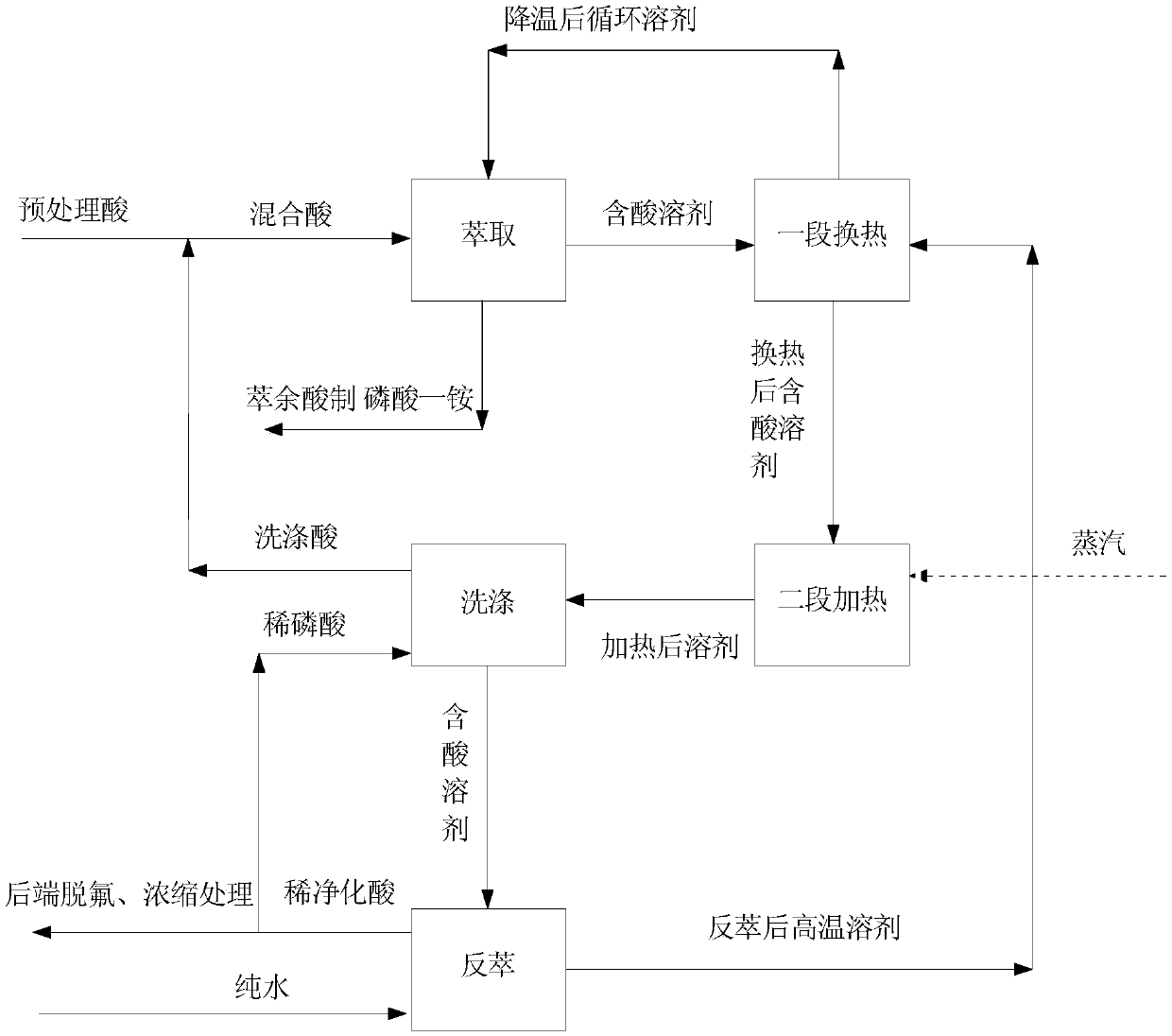

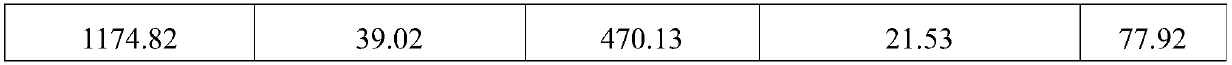

[0055] 1. Extraction: Prepare a mixed solvent containing tributyl phosphate and kerosene with a specific gravity of 0.93. After the centrifugal extractor rotates to 3000r / min, the pretreated acid is sent to the heavy phase of the first-stage extraction centrifuge at a rate of 555ml / min by a metering pump. At the inlet, the mixed solvent is sent to the light phase inlet of the third-stage extraction centrifuge with a metering pump at 2220ml / min for three-stage countercurrent extraction, the extraction ratio is 4:1, the temperature is 20°C-25°C, and the raffinate is passed through the third The heavy phase outlet of the first stage is discharged; the acid-containing solvent is discharged th...

Embodiment 2

[0064] The pretreatment acid index is as follows:

[0065] raw material name

[0066] 1. Extraction: Prepare a mixed solvent containing tributyl phosphate and kerosene with a specific gravity of 0.93. After the centrifugal extractor rotates to 3000r / min, the pretreated acid is sent to the heavy phase of the first-stage extraction centrifuge at a rate of 555ml / min by a metering pump. At the inlet, the mixed solvent is sent to the light phase inlet of the third-stage extraction centrifuge with a metering pump at 2220ml / min for three-stage countercurrent extraction, the extraction ratio is 4:1, the temperature is 35°C-40°C, and the raffinate is passed through the third The heavy phase outlet of the first stage is discharged; the acid-containing solvent is discharged through the light phase outlet of the first stage extraction centrifuge, and then exchanges heat with the circulating solvent through a heat exchanger, and then enters the washing section after being heated b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com