Diameter and pitch variable elbow equipment

A pipe bending equipment and variable pitch technology, which is applied in the field of pipe bending equipment, can solve the problems of pits and other problems on the surface of the pipe bending, and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

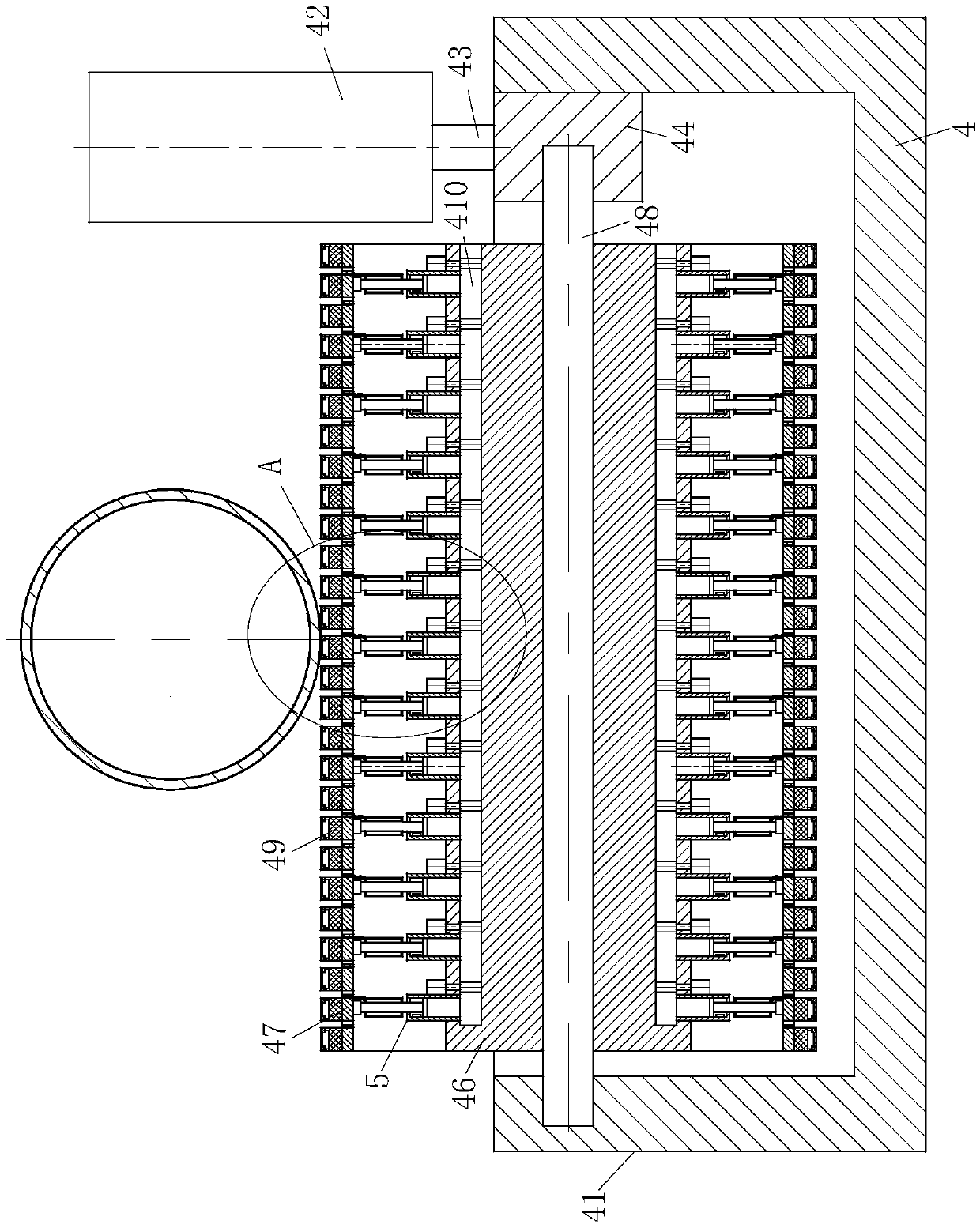

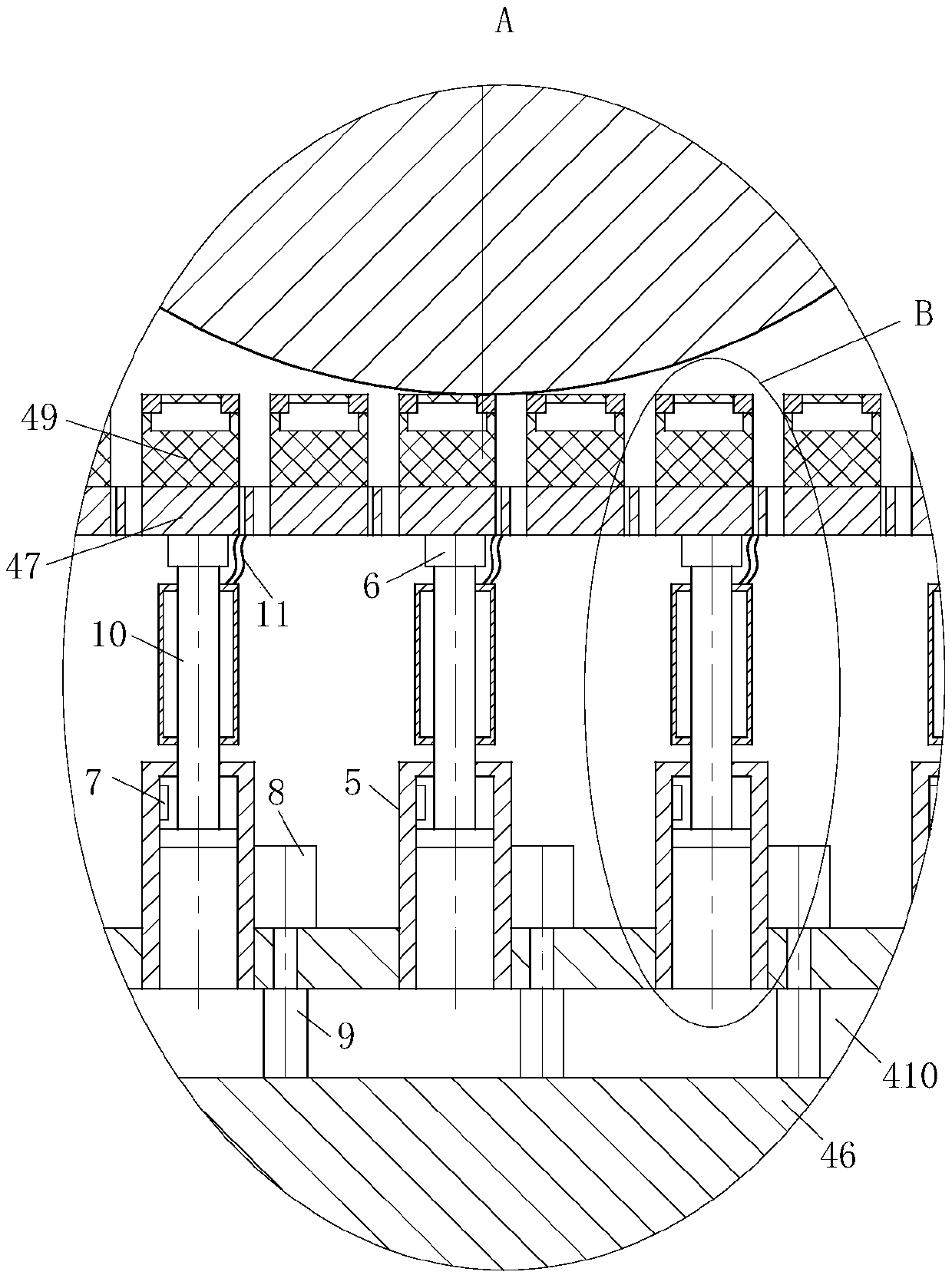

[0019] use Figure 1-Figure 4 A variable-diameter variable-pitch pipe bending equipment according to an embodiment of the present invention is described as follows.

[0020] Such as Figure 1-Figure 3As shown, a variable-diameter variable-pitch pipe bending equipment according to the present invention includes a first rotating roller 1, a second rotating roller 2 and a support roller 3. There are two first rotating rollers 1 horizontally, and two first rotating rollers Roller 1 is used to introduce the metal pipe, and there is a second roller 2 on the upper right of the two first rollers 1. The second roller 2 is used to bend the metal pipe. The first roller 1 and the second roller 2 There are two support rollers 3 on one side, the first rotating roller 1, the second rotating roller 2 and the supporting roller 3 are all driven by motors, and an adjustment module 4 is also included, and the adjustment module 4 is located at the middle position of the two supporting rollers 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com