Foam suspension cleaning system

A cleaning system and suspending technology, applied in the field of automobile beauty equipment, can solve the problems of optical rotation, paint damage, low working efficiency and sewage, and achieve the effect of ensuring safety, avoiding scratches and saving water resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

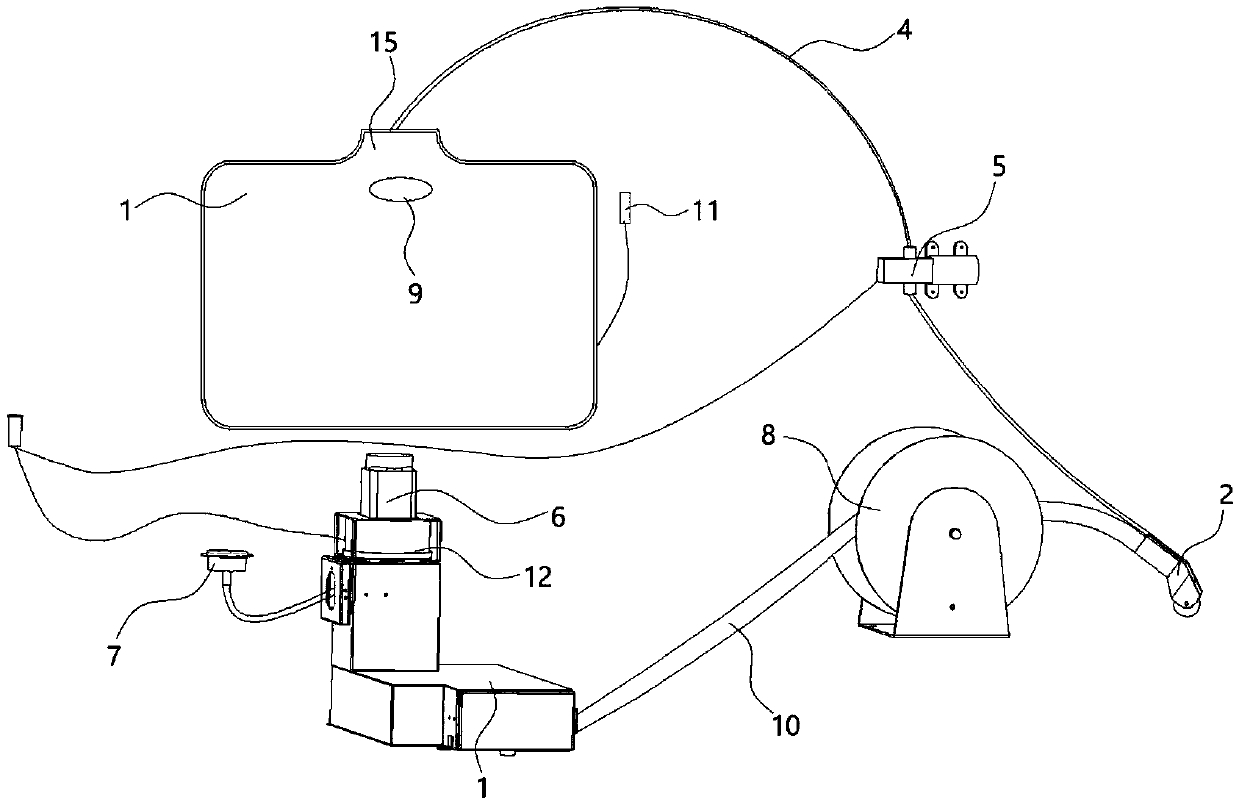

[0022] Such as figure 1 As shown, the foam suspension cleaning system provided by the present invention includes a negative pressure chamber 1, an adsorption disk 2, a water tank 3, a pipe 4, a pressure pump 5, and a reel 8 around which a negative pressure tube is arranged.

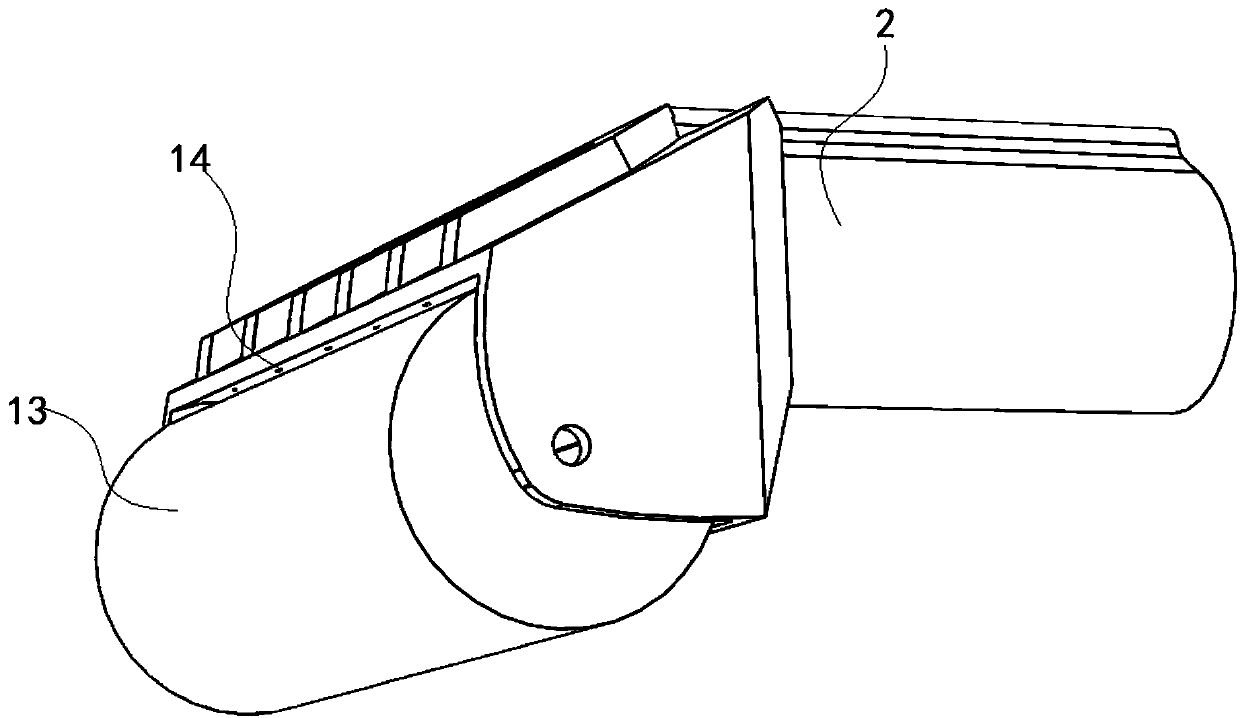

[0023] The negative pressure chamber 1 is provided with a negative pressure motor 6 and a negative pressure gauge 7. The inlet of the negative pressure motor 6 is provided with a filter element 12; the adsorption tray 2 is provided with an adsorption chamber, and the outlet end of the adsorption chamber is connected to the negative pressure chamber 1 through a negative pressure tube , The negative pressure motor 6 generates negative pressure on the adsorption disk 2, and the negative pressure can absorb the dirt and foam on the paint surface of the car, and collect the water in the negative pressure chamber 1. The inlet end of the adsorption chamber is detachably provided with a soft contact piece 13. The sof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com