Preparation method of NiB/PANI nanofiber catalyst and application thereof in hydrogen production by sodium borohydride hydrolysis

A nanofiber and composite nanofiber technology is applied in the field of synthesizing composite catalysts, which can solve the problems of poor recycling effect and low catalyst immobilization strength, and achieve the effects of reducing preparation cost, improving recycling rate, and easy and fast operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

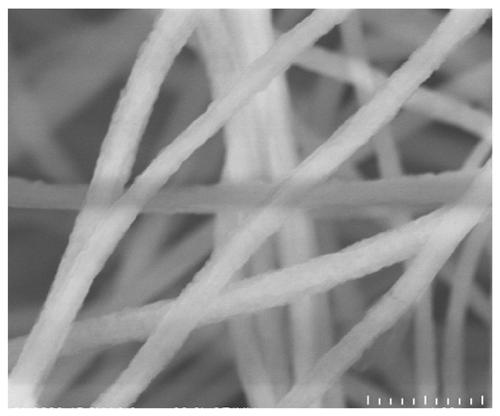

[0035] Using PS (polystyrene) and DMF (N, N-dimethylformamide) as raw materials, prepare a PS-DMF solution (polystyrene-dimethylformamide solution) with a concentration of 10.0 wt%, and pass through a magnetic stirrer Stir for 5-6 hours to obtain an electrospinning precursor solution. The precursor solution was placed in a syringe for electrospinning. The electrospinning process conditions were as follows: the voltage was 18kV; the speed of the receiver drum was 2000r / min; the receiving distance was 15cm. The prepared PS nanofibers were placed in a vacuum oven for 2-3 hours, and finally samples were taken for later characterization.

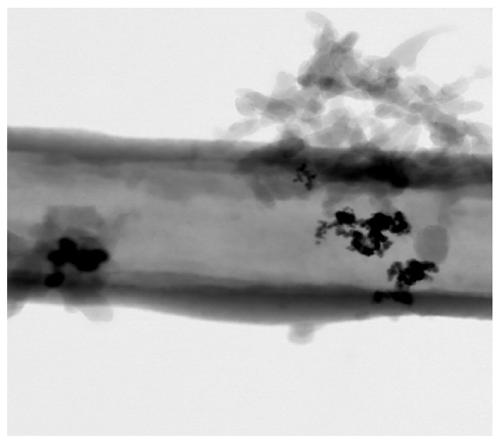

[0036] Soak the PS nanofibers prepared above in concentrated sulfuric acid for 4 hours, and carry out sulfonation reaction at a constant temperature of 40°C. After the reaction was finished, it was repeatedly washed with distilled water made in the laboratory, then filtered with suction, and then dried in vacuum for nearly 12 hours for later use...

Embodiment 2

[0039] Using PS (polystyrene) and DMF (N, N-dimethylformamide) as raw materials, prepare a PS-DMF solution (polystyrene-dimethylformamide solution) with a concentration of 12.5wt%, and pass through a magnetic stirrer Stir for 5-6 hours to obtain an electrospinning precursor solution. The precursor solution was placed in a syringe for electrospinning. The electrospinning process conditions were as follows: the voltage was 18kV; the speed of the receiver drum was 2000r / min; the receiving distance was 15cm. The prepared PS nanofibers were placed in a vacuum oven for 2-3 hours, and finally samples were taken for later characterization.

[0040] Soak the PS nanofibers prepared above in concentrated sulfuric acid for 4 hours, and carry out sulfonation reaction at a constant temperature of 40°C. After the reaction was finished, it was repeatedly washed with distilled water made in the laboratory, then filtered with suction, and then dried in vacuum for nearly 12 hours for later use....

Embodiment 3

[0043] Using PS (polystyrene) and DMF (N, N-dimethylformamide) as raw materials, prepare a PS-DMF solution (polystyrene-dimethylformamide solution) with a concentration of 15.0 wt%, and pass through a magnetic stirrer Stir for 5-6 hours to obtain an electrospinning precursor solution. The precursor solution was placed in a syringe for electrospinning. The electrospinning process conditions were as follows: the voltage was 18kV; the speed of the receiver drum was 2000r / min; the receiving distance was 15cm. The prepared PS nanofibers were placed in a vacuum oven for 2-3 hours, and finally samples were taken for later characterization.

[0044] Soak the PS nanofibers prepared above in concentrated sulfuric acid for 4 hours, and carry out sulfonation reaction at a constant temperature of 40°C. After the reaction was finished, it was repeatedly washed with distilled water made in the laboratory, then filtered with suction, and then dried in vacuum for nearly 12 hours for later use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com