Electrocatalytic material for converting nitrogen gas into ammonia gas

A technology of electrocatalytic materials and nitrogen, which is applied in the field of electrocatalytic materials, can solve the problems of complex preparation process, low conductivity, and limitation of electrocatalytic performance of pure titanium dioxide, and achieve the effects of high preparation efficiency, good product quality, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

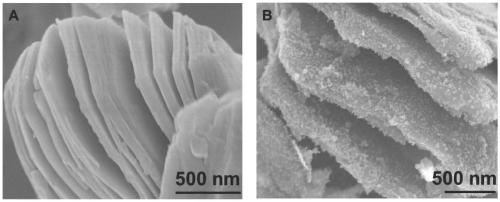

[0036] The one-step hydrothermal method involved in this embodiment prepares the nitrogen reduction electrocatalyst, and the specific process steps of the method are carried out as follows:

[0037] S1, use Ti 3 AlC 2 Preparation of pure Ti from precursor 3 C 2 T x MXene;

[0038] (1), weigh 4g Ti 3 AlC 2 Put the powder in a 250mL polypropylene bottle and put it on a magnetic stirrer with a rotation speed greater than 200 rpm;

[0039] (2), press 1g Ti into the polypropylene bottle in step (1) 3 AlC: 10mL of hydrofluoric acid solution, slowly drop 40mL of hydrofluoric acid solution with a mass fraction of 49%, and react at room temperature for 24h under stirring at more than 200 rpm;

[0040] (3) After the reaction, take out the suspension in the polypropylene bottle and put it into a centrifuge tube, place the centrifuge tube symmetrically in the centrifuge, and centrifuge at a speed greater than 7000 rpm for more than 10 minutes to obtain a centrifuge After solutio...

Embodiment 2

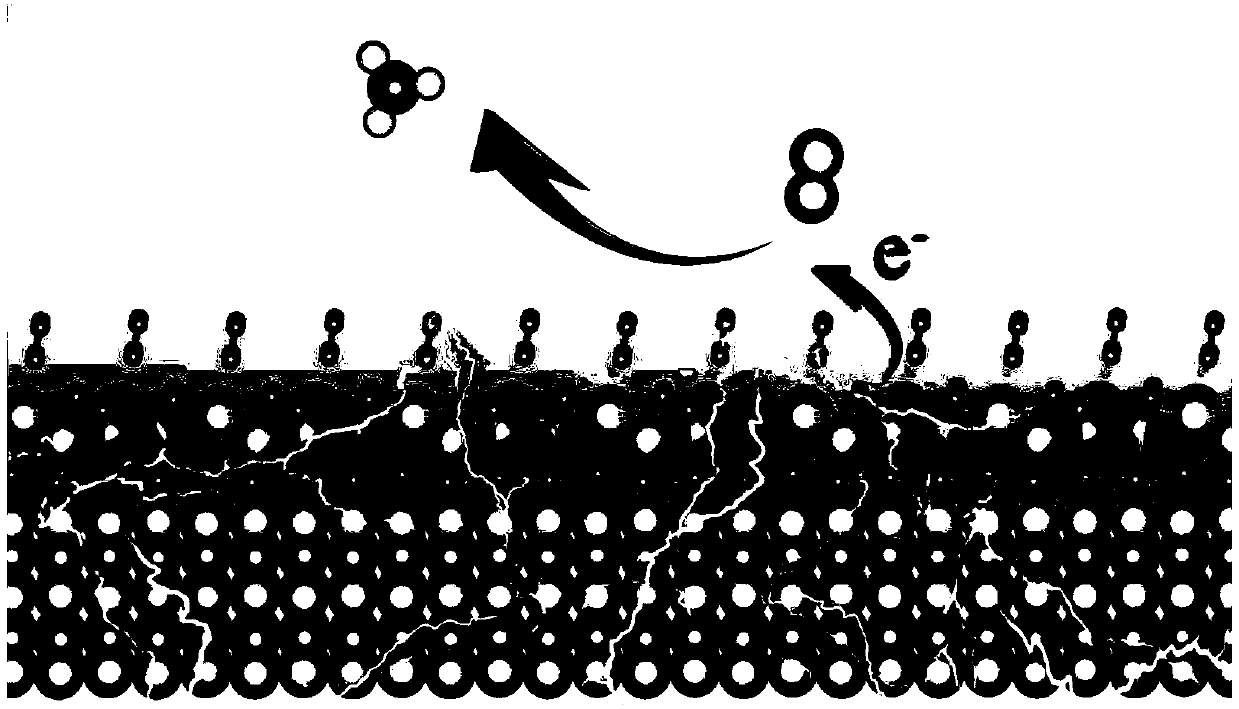

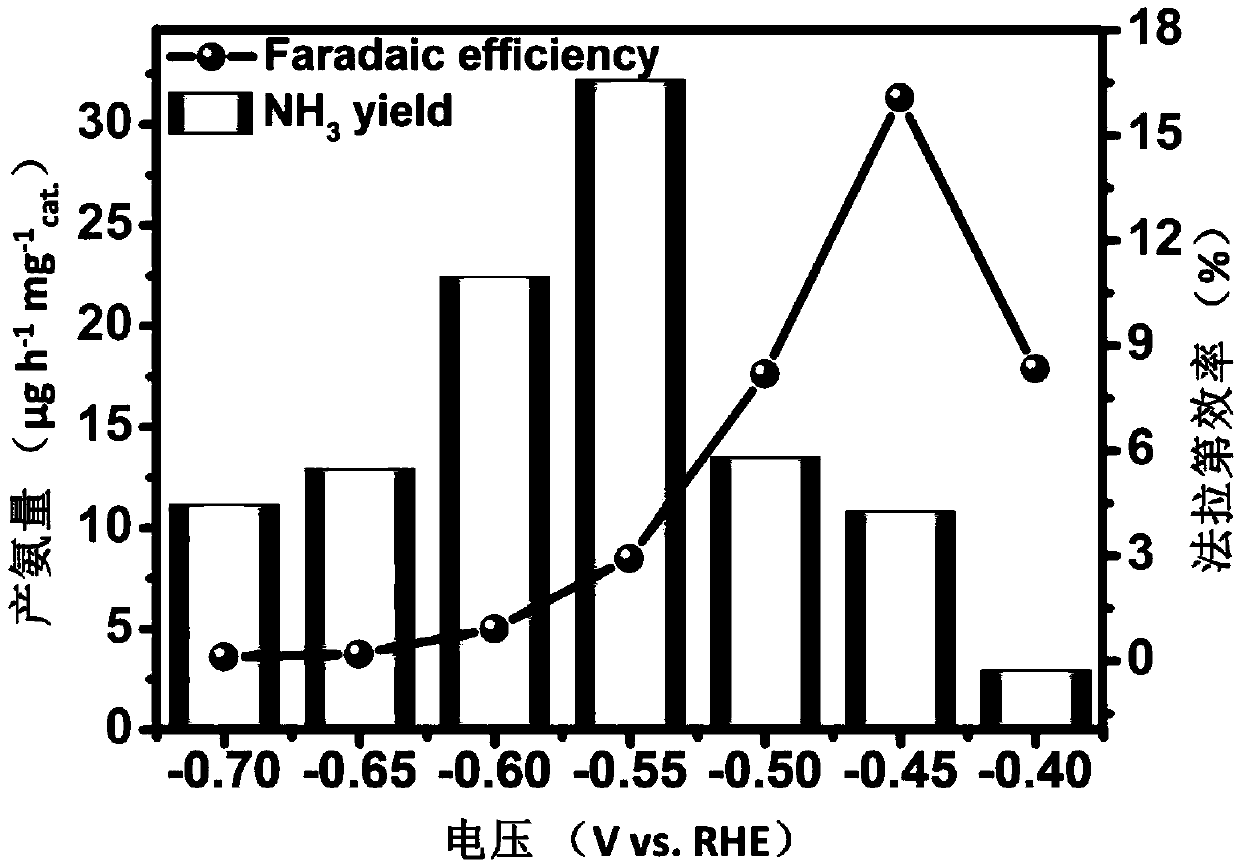

[0062] The present invention is to the pure Ti of preparation 3 C 2 T x MXene and layered Ti 3 C 2 T x / TiO 2 The nitrogen reduction properties of nanocomposites were tested and found that Ti 3 C 2 T x / TiO 2 The ammonia production of the nanocomposite can reach 32.17μg h at -0.55V -1 mg –1 cat .Its Faraday efficiency can reach 16.07% at -0.45V, which is higher than that of pure Ti 3 C 2 T x MXene and TiO 2 Ammonia production and Faraday of nanoparticles, and Ti 3 C 2 T x / TiO 2 The catalytic efficiency of the nanocomposite is higher than that of most current electrocatalysts. Show Ti 3 C 2 T x / TiO 2 The nanocomposite is a very good nitrogen reduction material, which can be applied to the field of nitrogen reduction; it shows that the layered Ti prepared in Example 1 3 C 2 T x MXene nanosheets are very good electrocatalytic materials and can be applied in the field of nitrogen reduction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com