Smoking set

A technology for smoking sets and cigarette sticks, which is applied in the field of heating equipment for low-temperature heating of cigarettes, to achieve the effect of lowering the temperature and saving heating energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

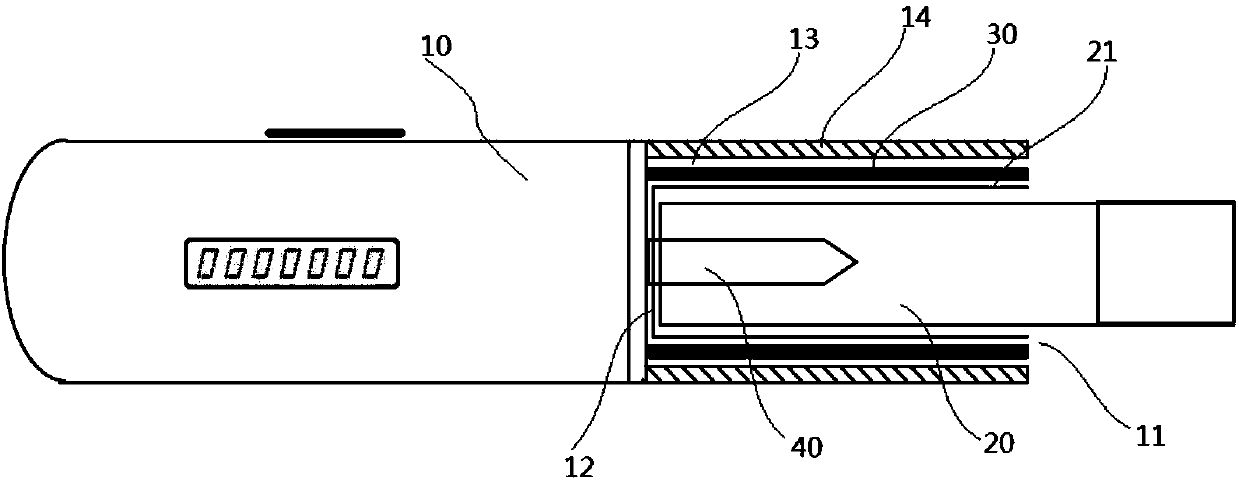

[0016] figure 1 It is a structural schematic diagram of the smoking appliance of this embodiment. The smoking appliance in this embodiment includes a casing 10 and a power supply (not shown in the figure). The housing 10 is in the shape of a strip, which can be a rectangular parallelepiped, a cylinder or other required shapes. A power supply for power supply is provided in the housing 10. Preferably, a control circuit can be added, including but not limited to over-current protection control, temperature control , charge control, discharge control, heating mode control (continuous, pulse, temperature-controlled heating, etc.), etc., and are integrated with the power supply inside the housing 10, and the positive and negative poles of the power supply are electrically connected to the positive and negative poles of the heating device 40. The housing 10 also includes an opening 11, a cavity 12, and an airflow channel 13, and the opening 11 is arranged at the proximal end of the...

Embodiment 2

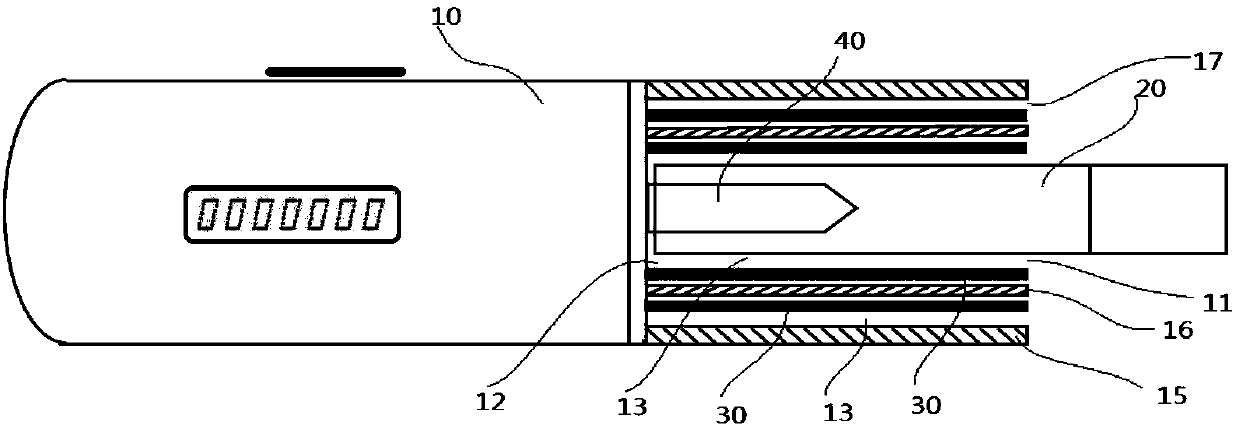

[0022] figure 2It is a structural schematic diagram of the smoking appliance of this embodiment. This embodiment is an extension of Embodiment 1. The difference between the two is that the housing 10 in this embodiment has an interlayer, and at least the tube wall of the housing 10 outside the cavity 12 has an interlayer, for example, the shell outside the cavity 12 The tube wall of the body 10 at least includes a first tube wall 15 outside the housing 10 and a second tube wall 16 inside the housing 10, so that air can flow in from the interlayer, that is, the first tube wall 15 and the second tube wall The gap between the walls 16 constitutes at least a part of said gas flow channel 13 . When the gap between the second tube wall 16 and the cigarette branch 20 is too small to allow the airflow to flow in or the influence on the temperature is negligible, it can be considered that all the airflow flows from the interlayer between the first tube wall 15 and the second tube wal...

Embodiment 3

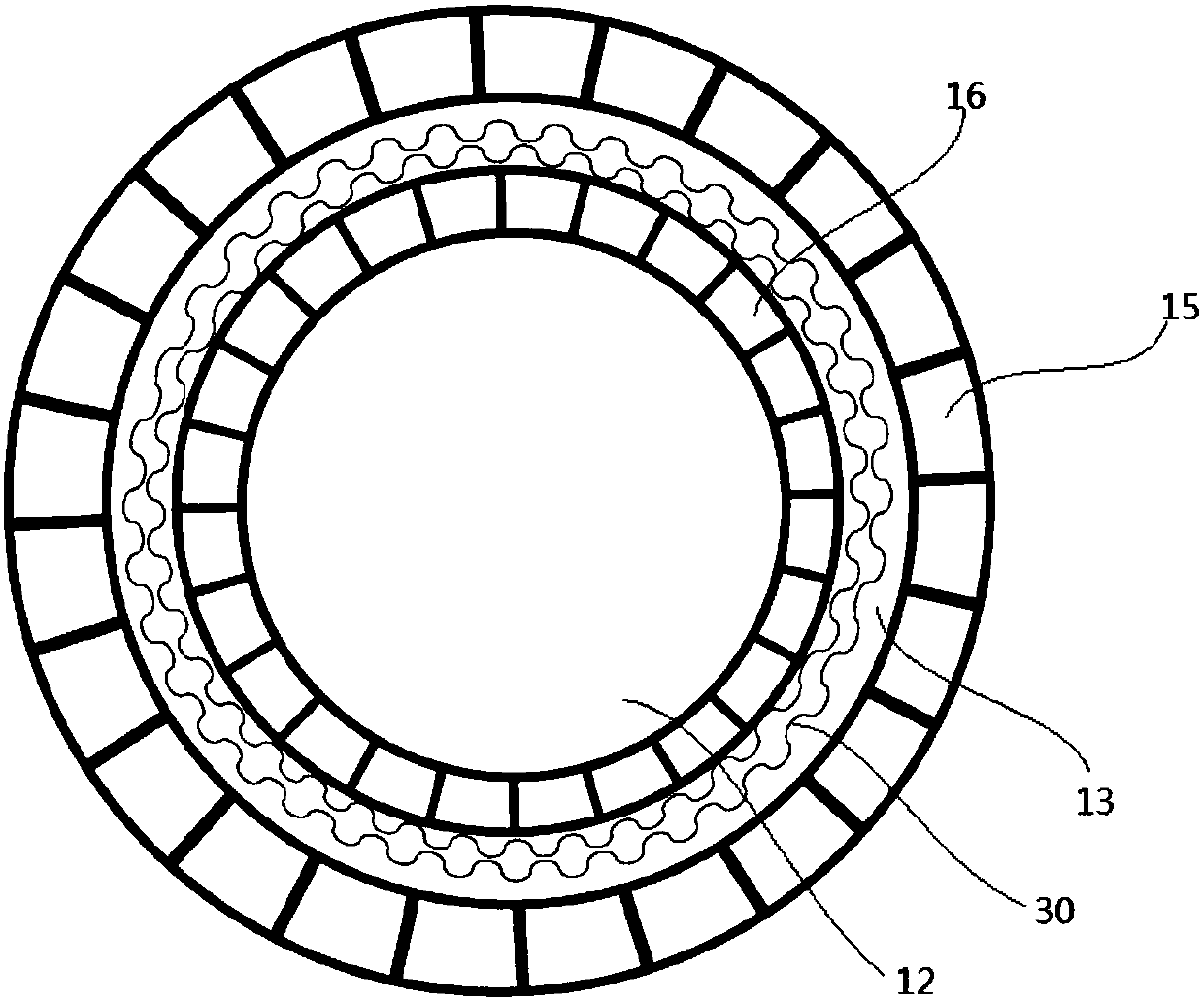

[0026] Figure 4 It is a structural schematic diagram of the smoking appliance of this embodiment. This embodiment is an extension of Embodiment 1, the difference between the two is that the smoking device in this embodiment also includes a heat sink located in the airflow channel 13 (not shown in the figure, the position coincides with the barrier layer 30) , the heat sink is made of thermally conductive material. For example, the tube wall 14 on the outside of the cavity 12 at least includes a first tube wall 15 outside the housing 10 and a second tube wall 16 inside the housing 10, so that air can flow in from the interlayer, and the cooling fins are arranged on the first tube wall 16. In the gap between the first tube wall 15 and the second tube wall 16 . Preferably, the heat sink is made of metal or ceramic material, that is, it can dissipate heat into the airflow channel 13 at a relatively fast speed in the airflow channel 13, and be taken away when smoking, or it can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com