Process for isolation of hemicelluloses from biomass pulping process waters or spent liquors

A technology of hemicellulose and process water, which is applied in the field of separating hemicellulose, can solve the problems of inability to transform into industrial applications and low product concentration, and achieve the effects of low processing cost, good separation, and easy reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

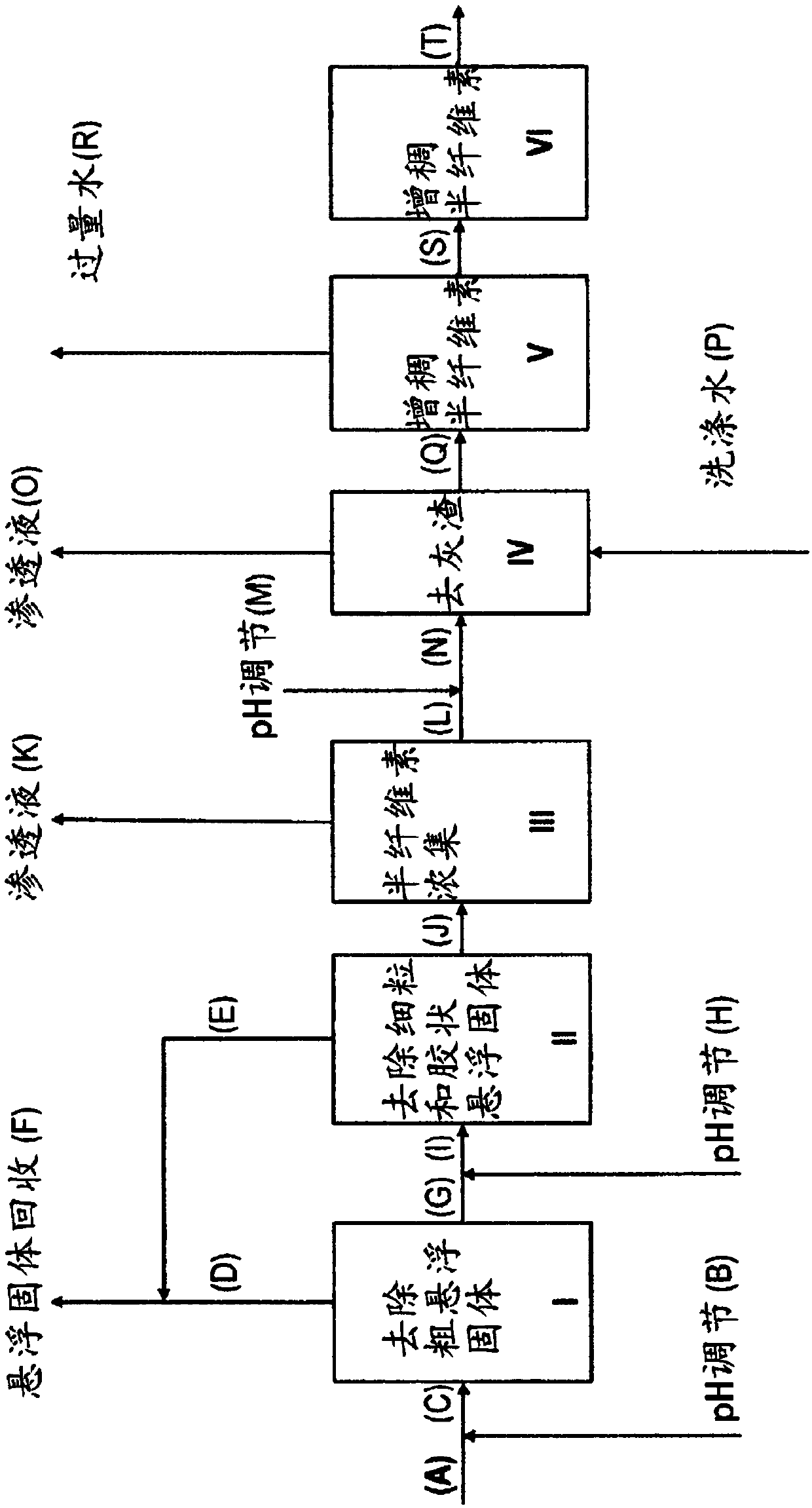

Image

Examples

Embodiment Construction

[0014] This process of separating hemicellulose can be used in mechanical pulping lines, semichemical and chemical pulping equipment. It can be implemented in existing equipment or in rebuilding projects. The process is suitable for biomass, hardwood (xylan) and softwood (polygalactose glucomannose (GGM)) pulping line process water and waste liquor treatment using high temperature water extraction or alkaline treatment of biomass.

[0015] Typical pulping lines for the separation of hemicellulose from process water, bleaching plants and waste liquors are:

[0016] - Hardwood kraft pulping plant with alkaline prehydrolysis

[0017] - Hardwood kraft pulping plants with an alkaline extraction stage before or after bleaching

[0018] -Hardwood NSSC semi-chemical pulping line

[0019] -Hardwood green liquor semi-chemical pulping production line

[0020] - Mechanical and semi-chemical pulping lines for annual plants (bagasse, kenaf, etc.)

[0021] -TMP process white water

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com