Cooling method of high-temperature metal and manufacturing method of hot-dip galvanized steel strip

A cooling method, hot-dip galvanizing technology, applied in the direction of metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of uneven cooling, insufficient improvement of cooling capacity, and inability to obtain a uniform structure, etc., to achieve a beautiful surface The effect of appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

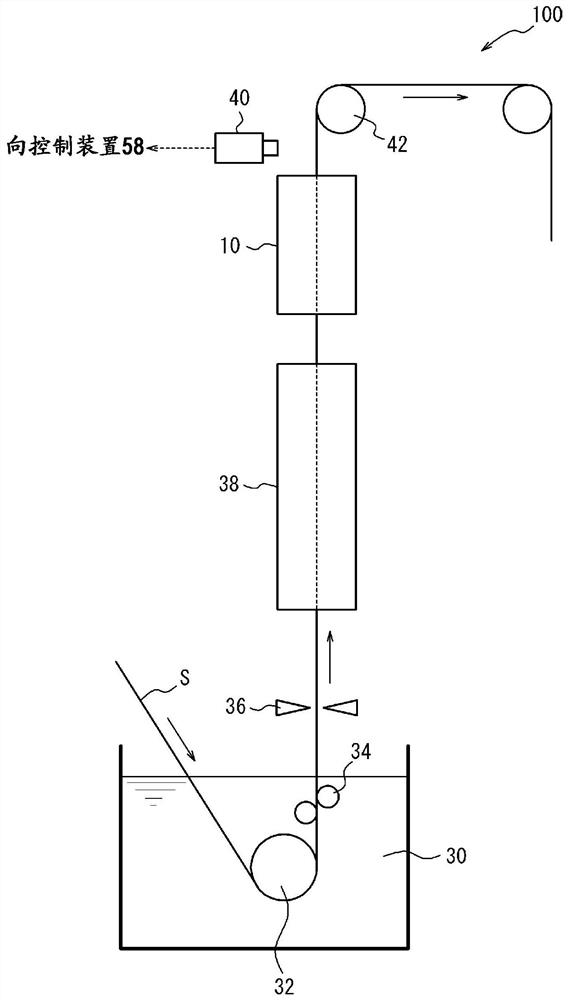

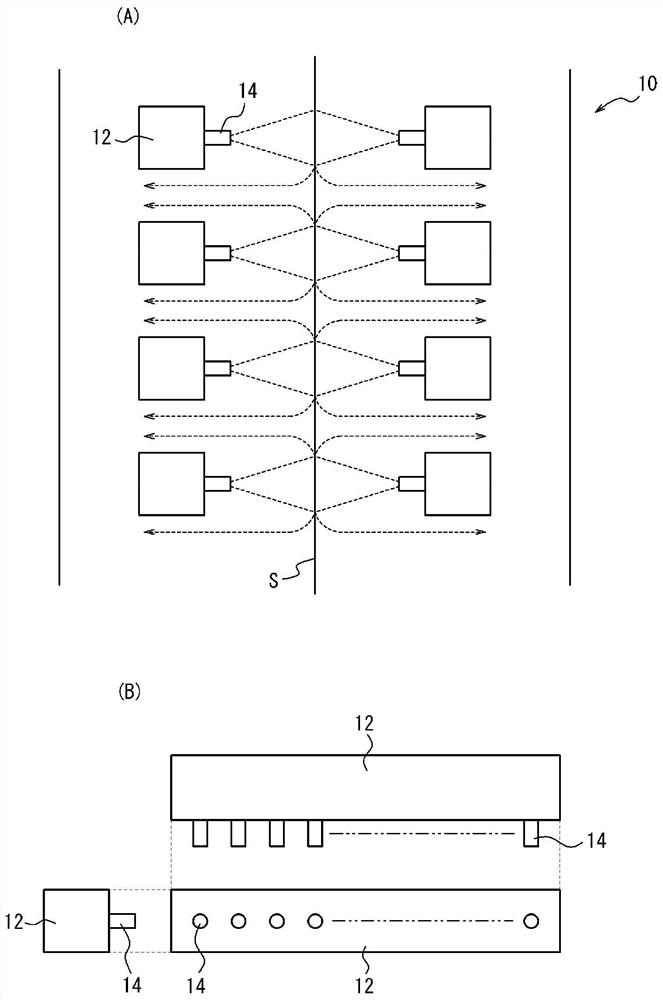

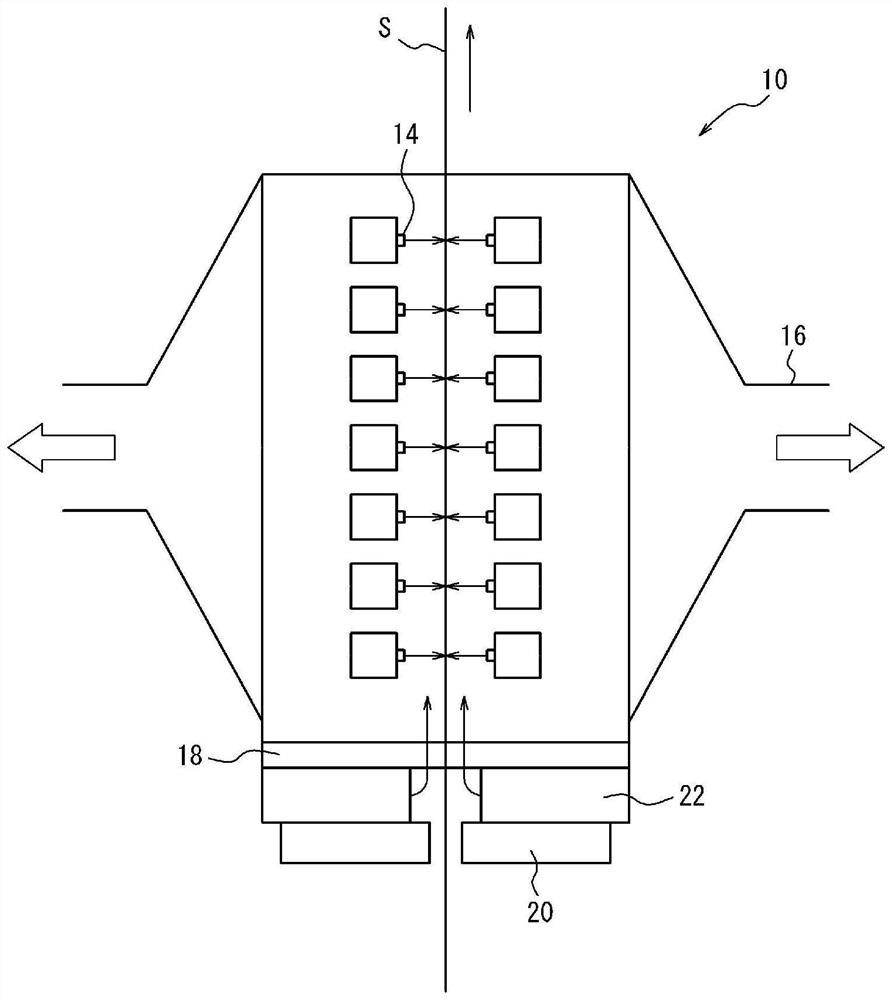

[0081] use Figure 1 ~ 4 The continuous alloying molten galvanized apparatus shown is manufactured under various conditions. The steel strip having a thickness of 1.2 mm x plate width 1000 mm after 1000 mm was passed through the apparatus with the line speed shown in Table 1. Immersion steel strips in the molten galvanized bath, adjust the zinc adult amount to 50 g / m by gas wiping 2 After the spray cooling device, the molten galvanized steel strip having a plating layer having a composition shown in Table 1 was obtained. In terms of the temperature of the plating bath, adjust to the appropriate value suitable for the composition of the coating and is shown in Table 1. Heating alloying of molten galvanized zinc is not performed in this example. Set an exhaust fan in the connecting portion of the shock absorber, with 3600m inventory 3 The fixed output power of / hr is running.

[0082] exist Figure 4 In the manufacturing system of the microbubble cooling water, a cooling water cont...

Embodiment 2

[0088] The molten galvanized steel strip is manufactured by the same conditions and method using the same conditions and method as in the present invention, in addition to the same conditions and methods as those of the inventive example NO. The coating composition and the bath temperature are set to invent No. 1, i.e., Al: 0.2% by mass, Zn: composition of the balance, and the bath temperature is 460 ° C.

[0089] In the example No. 22, use Figure 5 The manufacturing system of the microbubble cooling water is shown, and the transfer of microbubble cooling water is performed without using the pump, and supplied to the nozzle header. At this time, the pressure high pressure of the cooling water before microbubbles is 0.05 MPa to 0.3 MPa of NOPA.

[0090] In the example No. 23, a centrifugal pump (200SZM) made of a non-volumetric pump (200SZM) was used as a pump that was transferred from the reservoir to the nozzle header.

[0091] In the present embodiment, the amount of bubble aver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com