Coil current switching algorithm based on motion system of magnetic levitation planar motor of photo-etching machine

A planar motor and coil current technology, which is applied in the direction of controlling electromechanical brakes, controlling electromechanical transmission devices, control systems, etc., can solve the problems of coil big-end voltage, affecting control accuracy, and sudden change to zero, so as to reduce heat loss and avoid The effect of a sudden change in current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

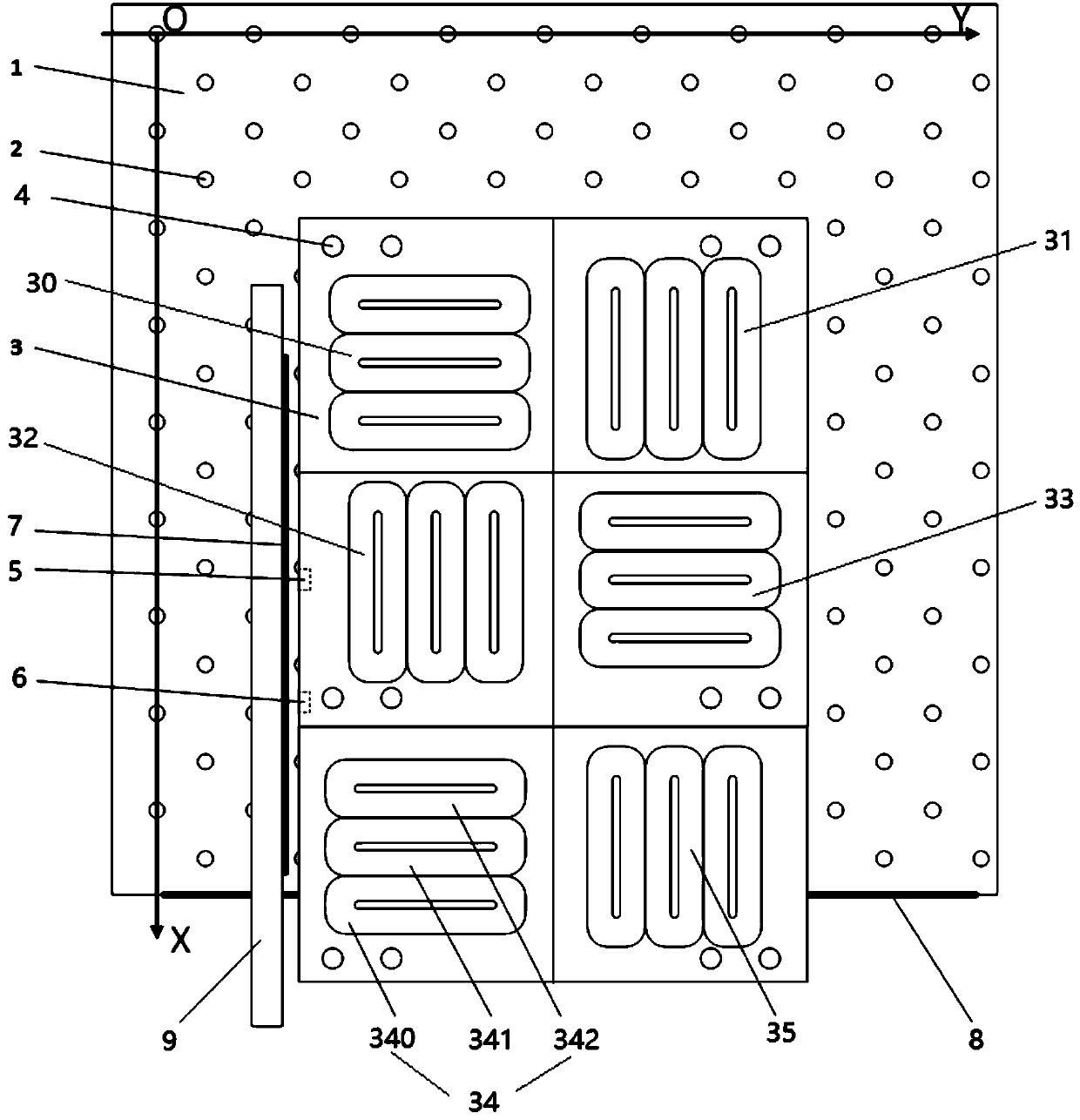

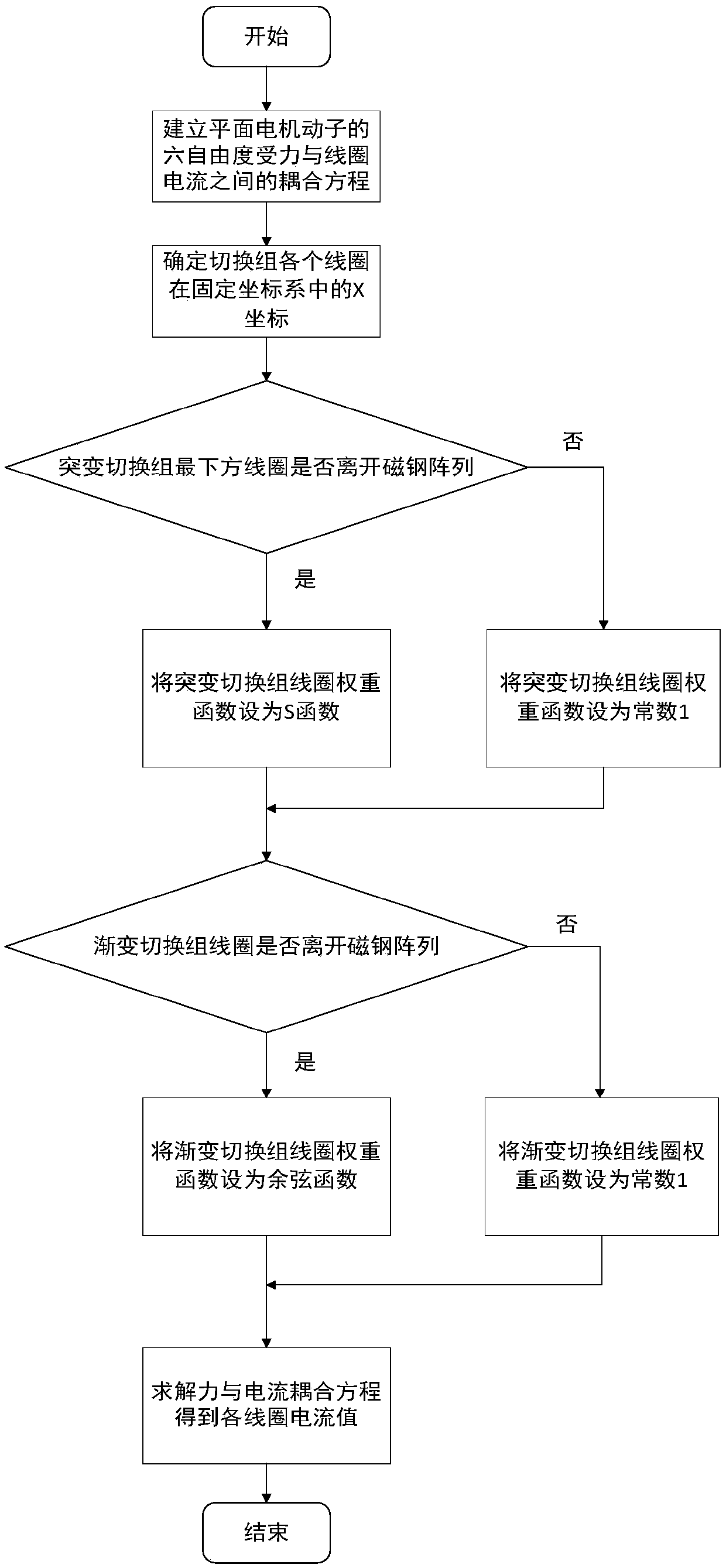

[0028] figure 1 A schematic structural diagram (top view) of the motion system adopted by the present invention is shown. figure 2 A schematic diagram (top view) of the structure of the double magnetic levitation worktable of the lithography machine adopted in the present invention is shown. The present invention provides a coil current switching algorithm based on the motion system of the maglev planar motor of a lithography machine, wherein the motion system includes a stator 1 and a planar motor mover 3, and the stator is a magnetic steel array, and its surface is processed with equidistantly arranged Cooling hole 2, planar motor mover 3 includes the first group of three-phase electrified coils 30, the second group of three-phase electrified coils 31, the third group of three-phase electrified coils 32, the fourth group of three-phase ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com