Mixed ion capacitor and preparation method thereof

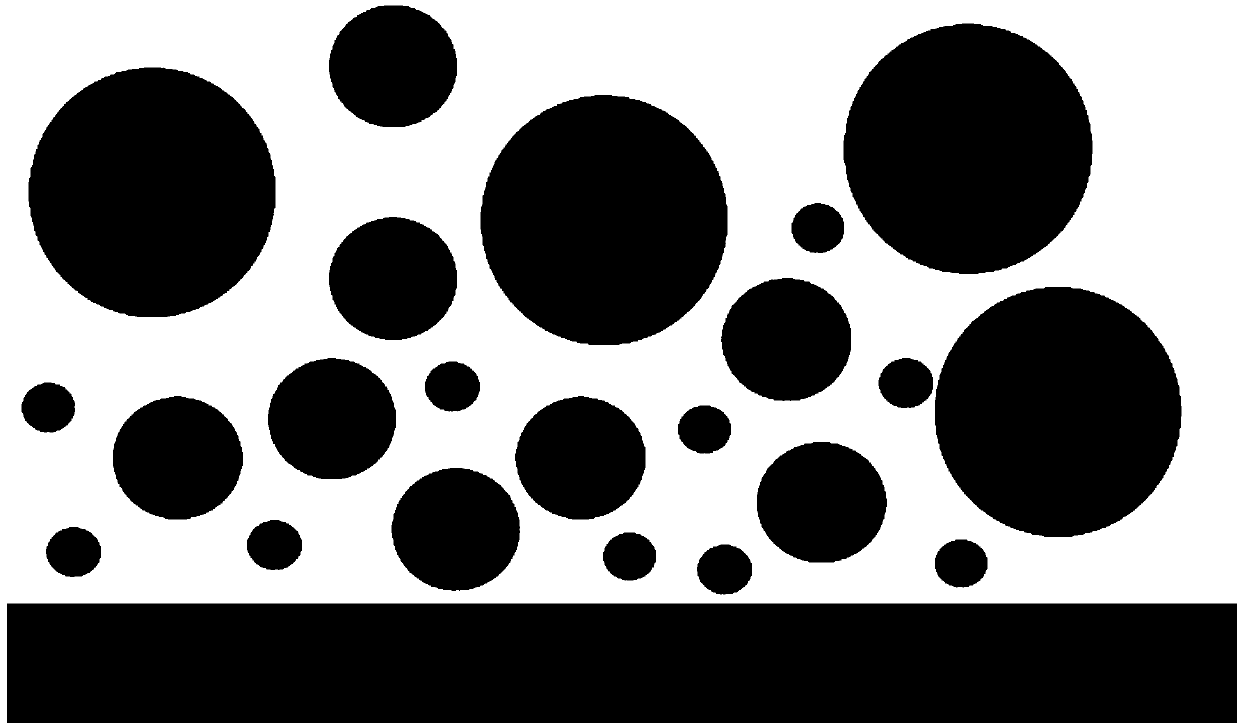

A capacitor and mixed ion technology, applied in the field of energy storage, can solve the problems of increased capacity and low energy density of supercapacitors, and achieve the effects of increasing energy density, improving the same ion effect, and reducing the cage effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment provides a preparation method of a mixed ion capacitor, using the following raw materials: lithium hexafluorophosphate, sodium perchlorate, dimethyl carbonate (DMC), vinyl ester (EC), capacitor carbon, conductive carbon black, PVDF; specific steps as follows:

[0040] First, lithium hexafluorophosphate and sodium perchlorate are dissolved in a solvent at a molar ratio of 1:1, and the solvent is configured from dimethyl carbonate (DMC) and vinyl ester (EC) at a volume ratio of 1:1. The concentration of the whole salt in the solvent is 1.2mol / L. The capacitor carbon material, conductive agent, and binder are mixed according to the mass ratio of 8:1:1 to prepare a slurry. The conductive agent is selected from conductive carbon black, and the binder is selected from PVDF. The slurry is coated on the aluminum film to prepare an electrode sheet. The prepared electrode sheet is dried in a vacuum oven to remove moisture from the electrode sheet. The drying ti...

Embodiment 2

[0043] This embodiment provides a preparation method of a mixed ion capacitor, using the following raw materials: lithium perchlorate, sodium hexafluorophosphate, potassium hexafluorophosphate, diethyl carbonate (DEC), ethylene carbonate (EC), methyl carbonate Ethyl ester (EMC), capacitor carbon, conductive agent, binder; the specific steps are as follows:

[0044] First, dissolve lithium perchlorate, sodium hexafluorophosphate, and potassium hexafluorophosphate in a solvent at a molar ratio of 1:1:1. The solvent consists of diethyl carbonate (DEC), ethylene carbonate (EC), methyl carbonate Ethyl ester (EMC) is configured according to the volume ratio of 1:1:1. The concentration of the whole salt in the solvent is 1.3 moles per liter. The capacitor carbon material, conductive agent, and binder are mixed according to the mass ratio of 8:1:1 to prepare a slurry. The conductive agent is selected from conductive carbon black, and the binder is selected from PVDF. The slurry is c...

Embodiment 3

[0052] This embodiment provides a preparation method of a mixed ion capacitor, using the following raw materials: sodium perchlorate, potassium hexafluorophosphate, propylene carbonate (PC), ethylene carbonate (EC), ethyl methyl carbonate (EMC), Capacitor carbon, conductive agent, binder; the specific steps are as follows:

[0053] First, sodium perchlorate and potassium hexafluorophosphate are dissolved in a solvent at a molar ratio of 1:1, and the solvent is composed of propylene carbonate (PC), ethylene carbonate (EC), and ethyl methyl carbonate (EMC) according to the volume ratio 1:1:1 ratio for configuration. The concentration of the whole salt in the solvent is 1.1 moles per liter. The capacitor carbon material, conductive agent, and binder are mixed according to the mass ratio of 8:1:1 to prepare a slurry. The conductive agent is selected from conductive carbon black, and the binder is selected from PVDF. The slurry is coated on the aluminum film to prepare an electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com