Capacitive magnetic field intensity sensor based on magnetic liquid drips

A magnetic liquid and sensor technology, applied in the field of sensor measurement, can solve problems such as inability to measure in real time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] to attach figure 1 The present invention will be further described for the specific embodiment:

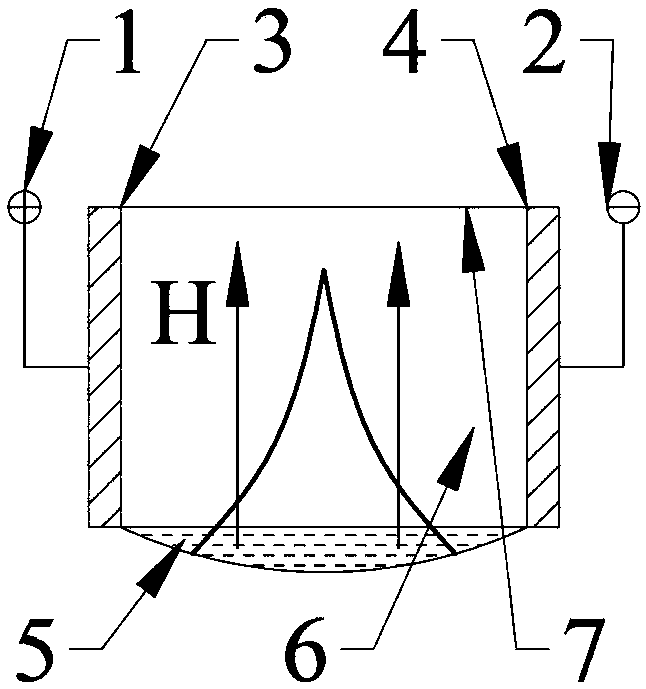

[0015] A capacitive magnetic field strength sensor based on magnetic liquid droplets, the sensor includes: a positive connection port 1, a negative connection port 2, a capacitor positive plate 3, a capacitor negative plate 4, a magnetic liquid droplet 5, and sealed air 6 , Seal the cavity 7.

[0016] The positive connection port 1 is connected to the positive electrode plate 3 of the capacitor, and the negative connection port 2 is connected to the negative electrode plate 4 of the capacitor. The positive electrode plate 3 of the capacitor and the negative electrode plate 4 of the capacitor are respectively located on both sides of the sealed cavity 6. Located at the bottom of the sealed cavity 7 , the sealed air 6 is located at the upper part of the sealed cavity 7 .

[0017] The overall size of the sensor is on the order of millimeters. When there is no external magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com