Plate glass defect rechecking system and rechecking method

A flat glass and defect technology, applied in the field of flat glass defect re-inspection system, can solve the problems of large size error of the re-inspection system and the inability to accurately detect the position of the defect, and achieve the effect of avoiding warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

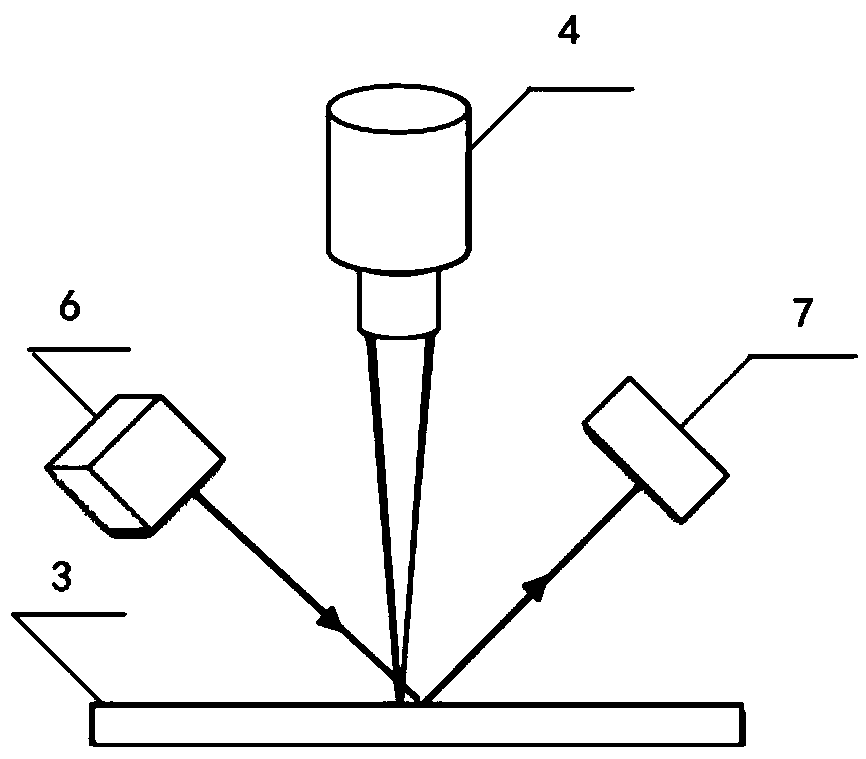

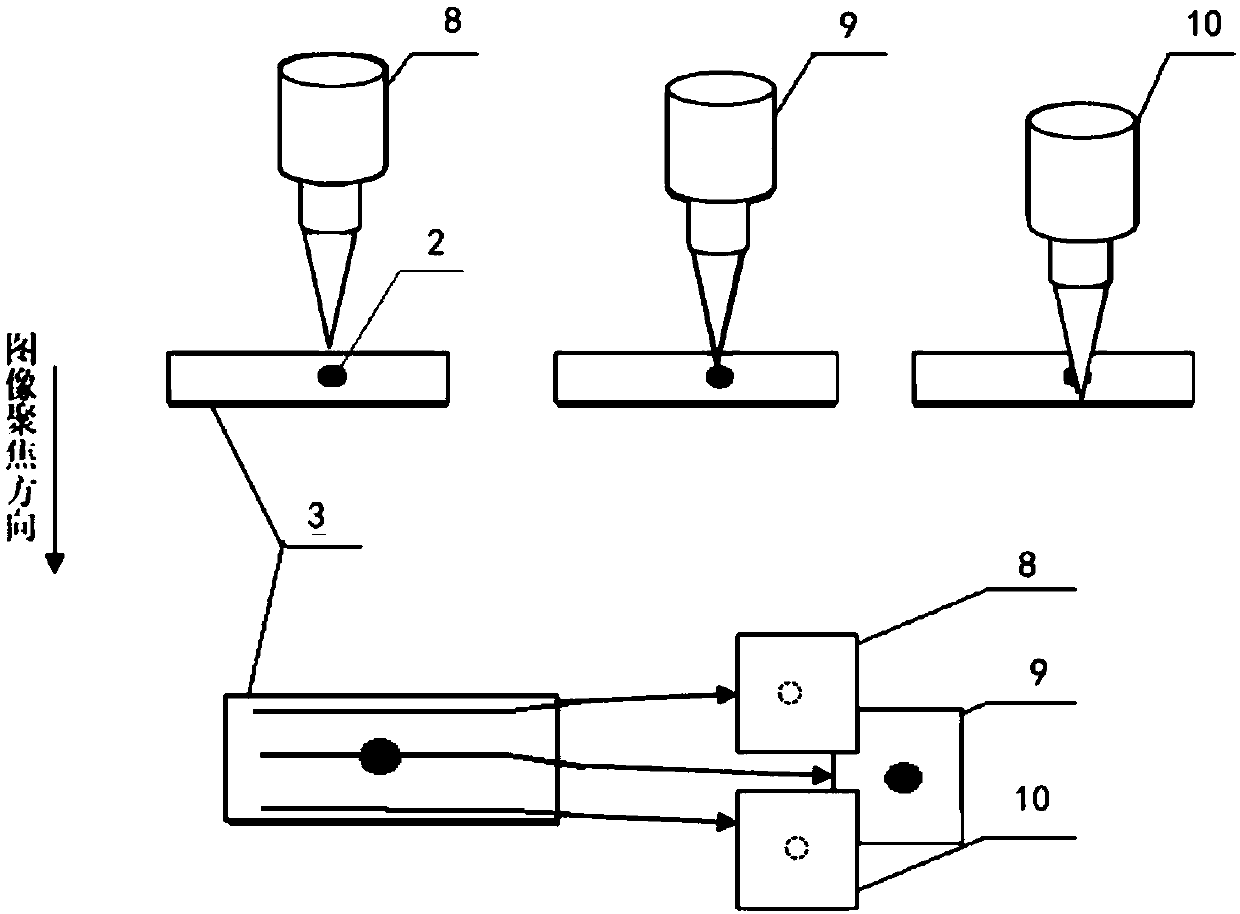

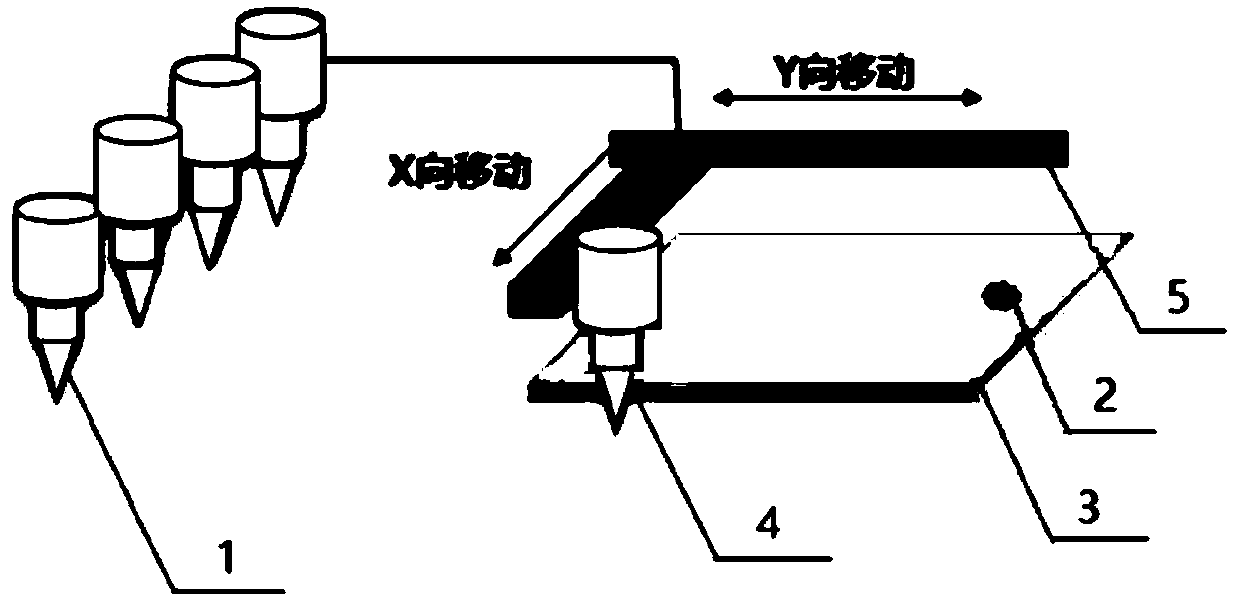

[0034] see figure 1 , the re-inspection system of the present invention is downstream of the conveyor line of the surface inspection system 1, and the re-inspection system includes a CCD probe 4, an X / Y transfer mechanism 5, a first laser sensor ranging system 11, and the first laser sensor ranging The system 11 includes a laser transmitter 6 and a photoelectric receiver 7; the X / Y direction transfer mechanism 5 is the supporting and moving driving mechanism of the entire re-inspection system, fixedly installed on the assembly line, and can move along the moving direction of the glass through the translation mechanism- The verticality of the X / Y transfer mechanism 5 is ≤2 / 10000; the X / Y transfer mechanism 5 is fixedly equipped with a CCD probe 4 and a laser emitter. The device 6 and the photoelectric receiver 7 are not in contact with each other; the CCD pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com