Thin type heat pipe, manufacturing method of thin type heat pipe and electronic equipment

A thin heat pipe and pipe body technology, applied in the field of heat pipes, can solve the problems of poor heat dissipation performance of a phase change heat dissipation structure, and achieve the effects of improving condensation effect, long circulation distance and high production yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

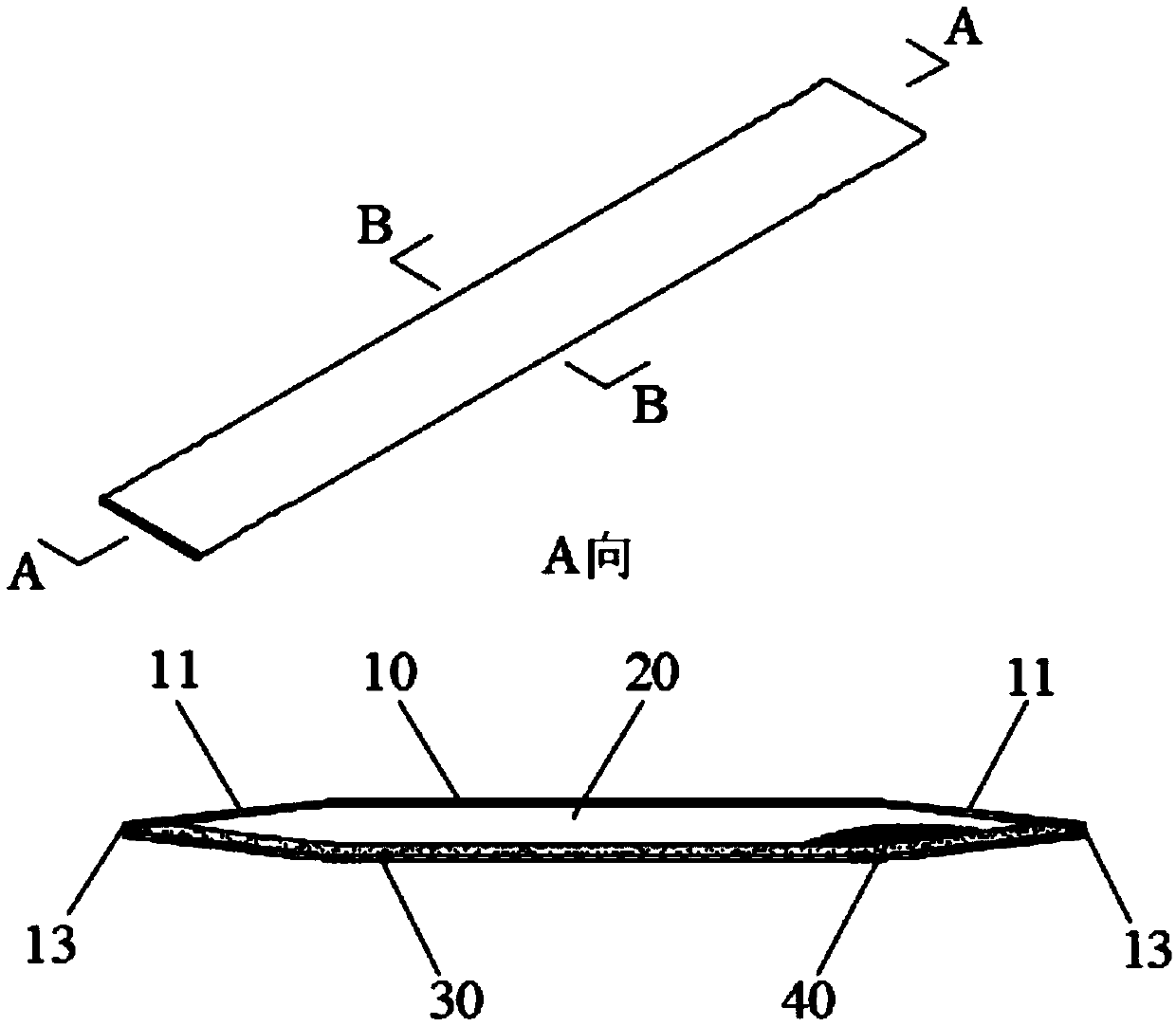

[0070] Before describing the technical solution of the embodiment of the present application, the technical scene of the embodiment of the present application will be described first with reference to the accompanying drawings.

[0071] In order to improve the cooling capacity of electronic products such as mobile phones and tablet computers, and reduce the temperature of the internal chips of electronic products when processing complex calculations or continuous high-load operation, some manufacturers use heat pipes (heat pipes, HP), vacuum chambers (vapor chambers) , VC), loop heat pipe (loop heat pipe, LHP) and other phase change heat dissipation technologies are applied in electronic products.

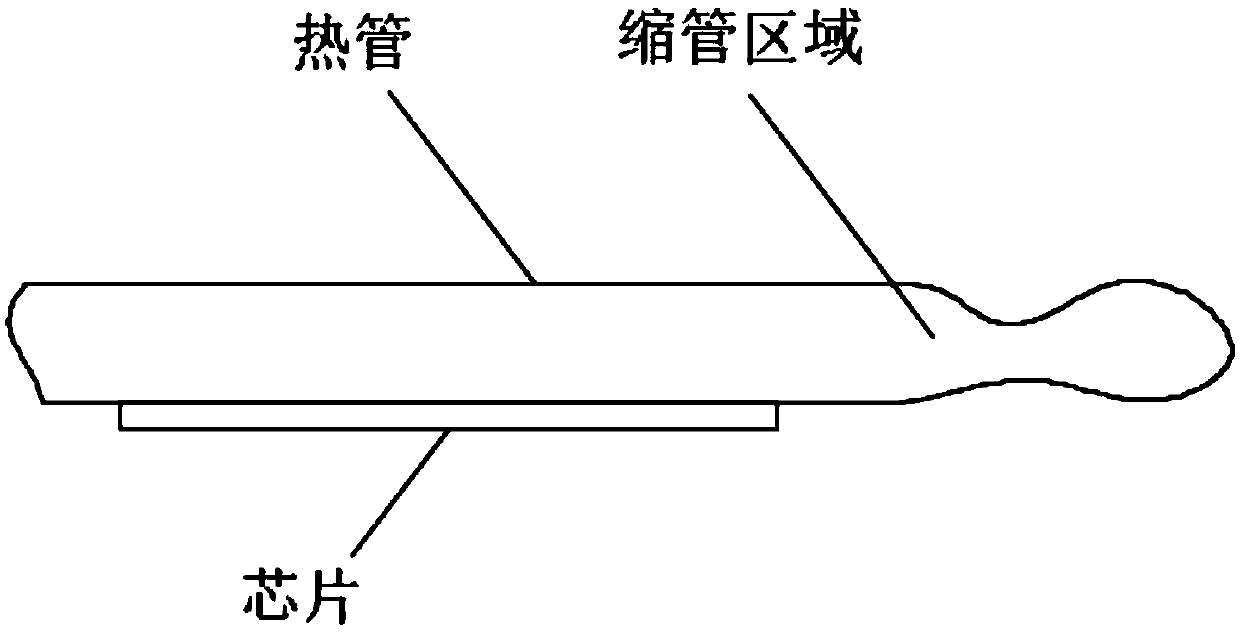

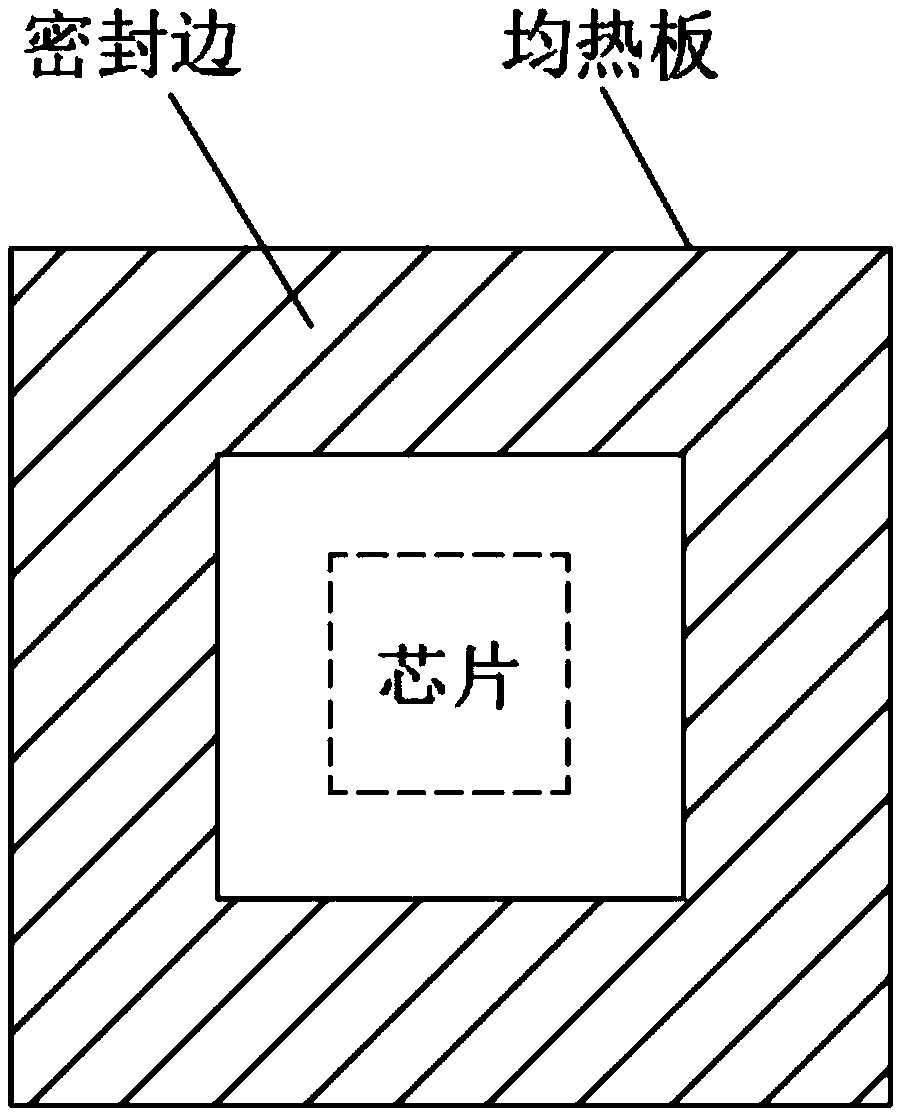

[0072] figure 1 A schematic diagram of the internal structure of an electronic device using heat pipe heat dissipation technology is shown. Such as figure 1 As shown, a heat pipe is arranged above the System on a Chip (SoC) of the mainboard of the electronic device, and the heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com