An Independent Control System of Inlet and Outlet with Pressure Compensation

A pressure compensation, independent control technology, applied in the direction of fluid pressure actuation system components, fluid pressure actuation system testing, fluid pressure actuation devices, etc. , to achieve fast response and efficient work, improve the effect of compensation pressure difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

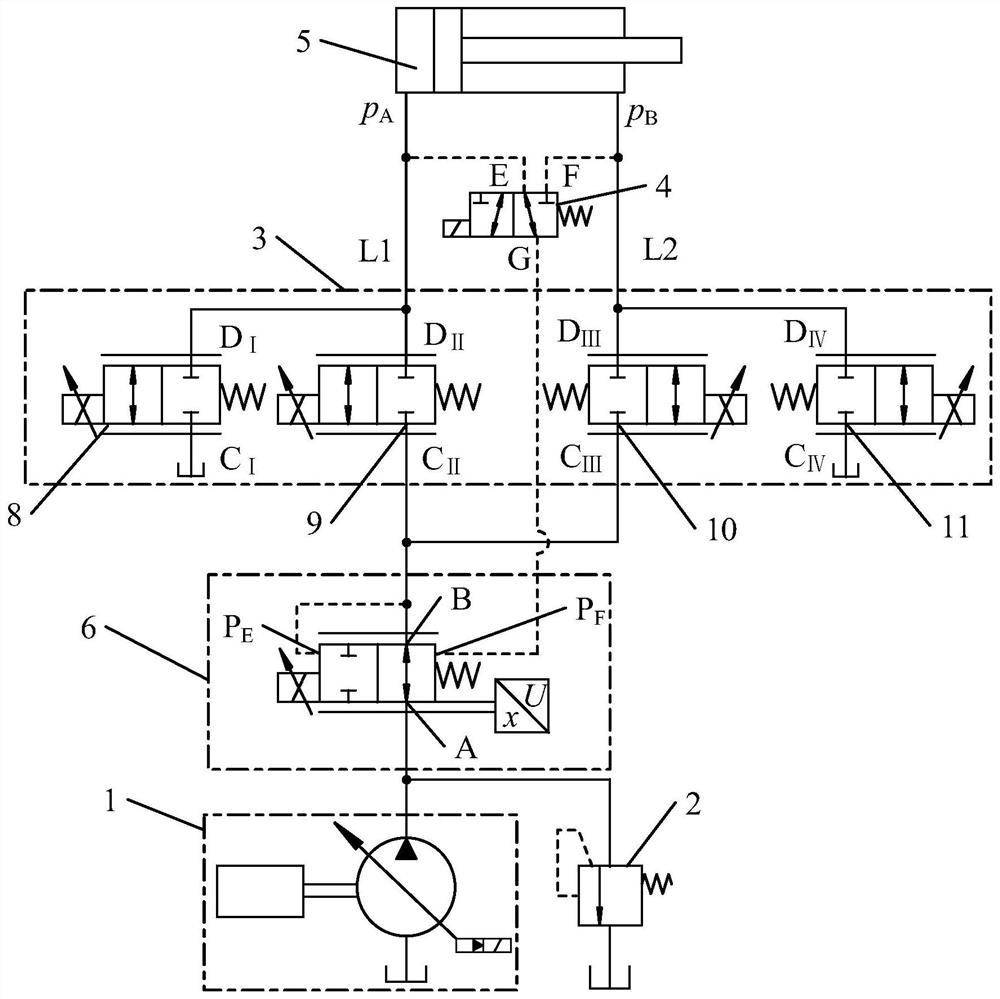

[0036] An independent control system for oil inlet and outlet with pressure compensation, including: hydraulic power source 1, overflow valve 2, independent inlet and outlet control valve group 3, hydraulic actuator 5; it is characterized in that it also includes a load selection valve 4, electronic Pressure compensation valve 6;

[0037] Such as figure 1 As shown, the import and export independent control valve group 3 is composed of the first two-position two-way proportional directional valve 8, the second two-position two-way proportional directional valve 9, the third three-position two-way proportional directional valve 10 and the fourth Two-position two-way proportional directional control valve 11;

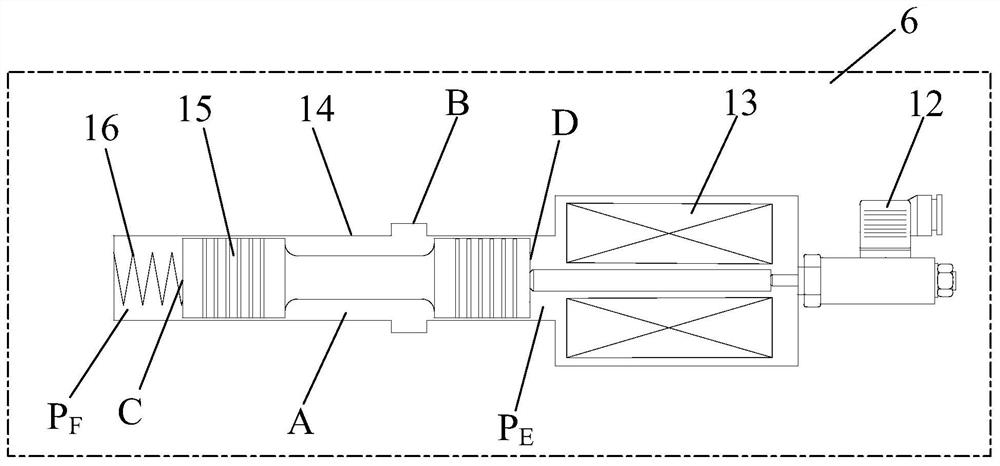

[0038] The oil inlet A of the electronic pressure compensation valve 6 is connected with the oil outlet of the hydraulic power source 1, and the oil outlet B of the electronic pressure compensation valve 6 is connected with the second control chamber P of the electronic p...

Embodiment approach

[0051] Such as Figure 5 As shown, the second embodiment of an independent control system for oil inlet and outlet with pressure compensation in the present invention differs from Embodiment 1 in that it includes an electro-hydraulic pressure compensation valve 7, and the hydraulic pump of the hydraulic power source 1 is a mechanical load sensing pump;

[0052] The LS oil circuit of the mechanical load sensing pump is connected with the first control chamber P of the electro-hydraulic pressure compensation valve 7 at the same time. F , The oil port G of the load selection valve 4 is connected. The oil inlet A of the electro-hydraulic pressure compensation valve 7 communicates with the oil outlet of the hydraulic power source 1, and the oil outlet B of the electro-hydraulic pressure compensation valve 7 communicates with the second control chamber P of the electro-hydraulic pressure compensation valve 7. E , Oil port C of the second two-position two-way proportional reversing...

Embodiment 3

[0059] Such as Figure 7 As shown, the third embodiment of a pressure-compensated oil inlet and outlet independent control system of the present invention differs from Embodiment 1 in that: the inlet and outlet independent control valve group 3 is composed of the first three-position three-way reversing valve 23 Constituted with the second three-position three-way reversing valve 24;

[0060] The oil inlet A of the electronic pressure compensation valve 6 is connected with the oil outlet of the hydraulic power source 1, and the oil outlet B of the electronic pressure compensation valve 6 is respectively connected with the oil inlet P of the first three-position three-way reversing valve 23. Ⅰ and the oil inlet P of the second three-position three-way reversing valve 24 Ⅱ Connected, the oil outlet T of the first three-position three-way reversing valve 23 Ⅰ And the oil outlet T of the second three-position three-way reversing valve 24 Ⅱ They are respectively connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com