Sealing structure and jar with sealing structure

A technology of sealing structure and jar, which is applied to engine sealing, wellbore/well parts, engine components, etc., can solve the problems of loss of sealing effect and equipment damage, etc., and achieve reasonable design of sealing structure, easy replacement and excellent performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

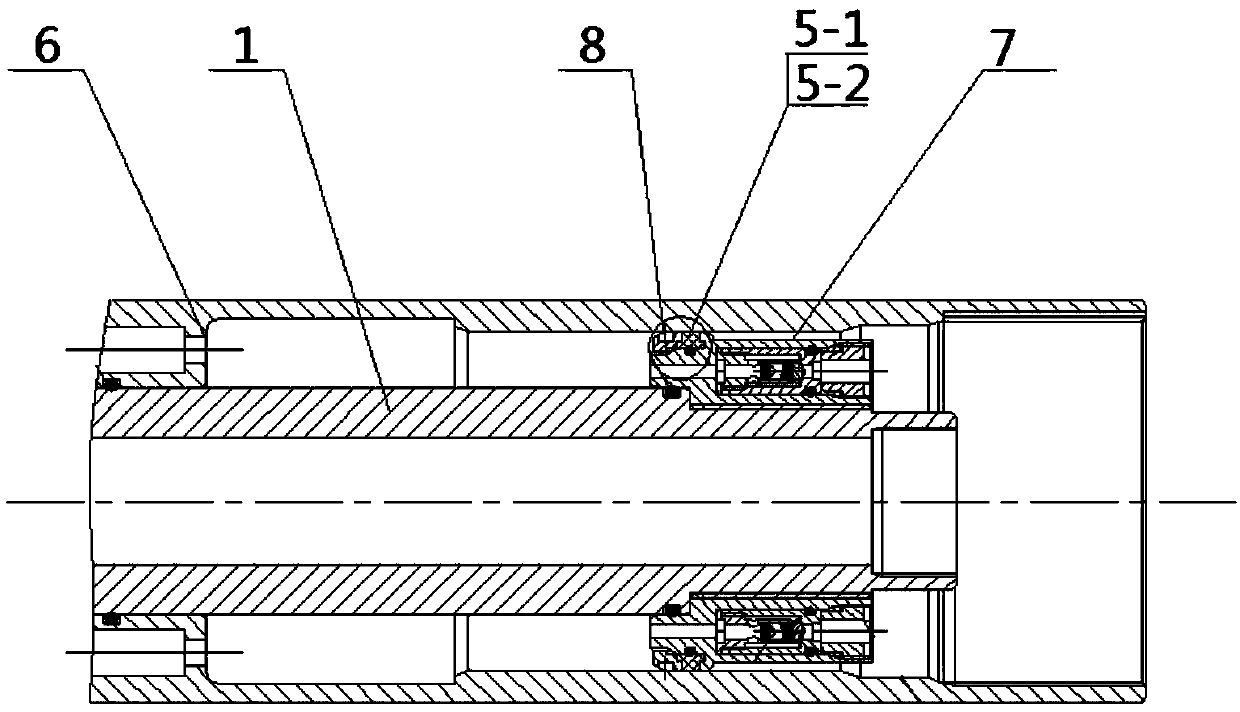

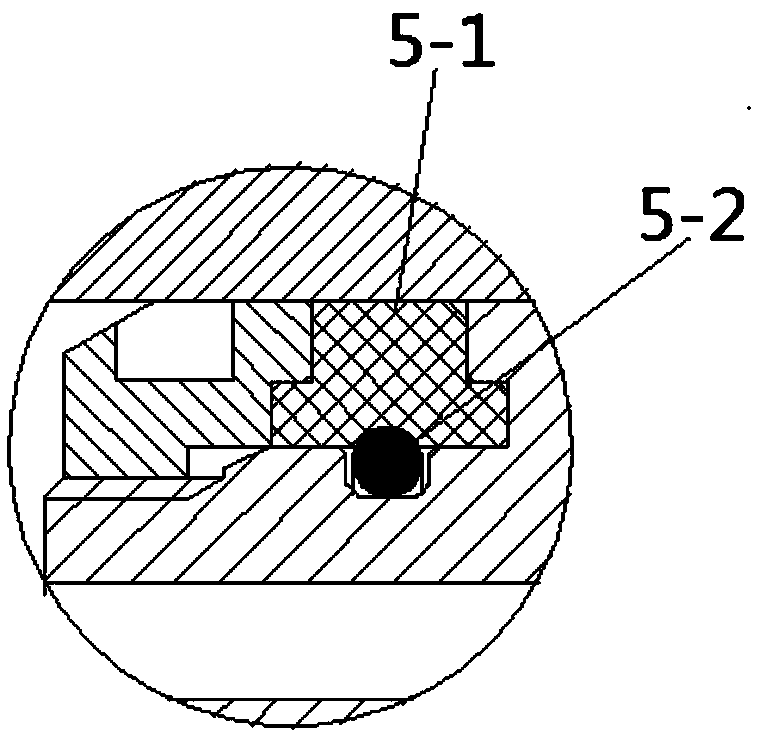

[0040] Such as figure 2 , when the shock shaft 1 is pulled up, the pressure in the high-pressure chamber rises, the hydraulic oil pushes the sealing piston 4 to move, and the sealing piston 4 pushes the push sleeve 3 to move. At this time, the push sleeve 3 is subjected to the elastic member 2 in the shock shell 6 Active force, so the greater the force of the elastic member 2, the higher the pressure in the high-pressure chamber. When the shock shaft 1 moves to a certain position, the pressure in the high-pressure chamber is released, and there is a process of pressure balance on both sides, which produces a sudden change in pressure. The vibration shaft 1 is connected with the vibration hammer 7, and the middle is sealed by a second O-ring. The shock shaft 1 and the shock housing 7 are sealed by a first O-ring. The vibration hammer 7 and the vibration shell 6 are sealed by a combined sealing ring, and the combined sealing ring is arranged between the vibration hammer 7 and...

Embodiment 2

[0043] Such as image 3, when the shock shaft 1 is pulled up, the pressure in the high-pressure chamber rises, the hydraulic oil pushes the sealing piston 4 to move, and the sealing piston 4 pushes the push sleeve 3 to move. At this time, the push sleeve 3 is subjected to the elastic member 2 in the shock shell 6 Active force, so the greater the force of the elastic member 2, the higher the pressure in the high-pressure chamber. When the shock shaft 1 moves to a certain position, the pressure in the high-pressure chamber is released, and there is a process of pressure balance on both sides, which produces a sudden change in pressure. The vibration shaft 1 is connected with the vibration hammer 7, and the middle is sealed by a second O-ring. The shock shaft 1 and the shock housing 7 are sealed by a first O-ring. The vibration hammer 7 and the vibration shell 6 are sealed by a combined sealing ring, and the combined sealing ring is arranged between the vibration hammer 7 and t...

Embodiment 3

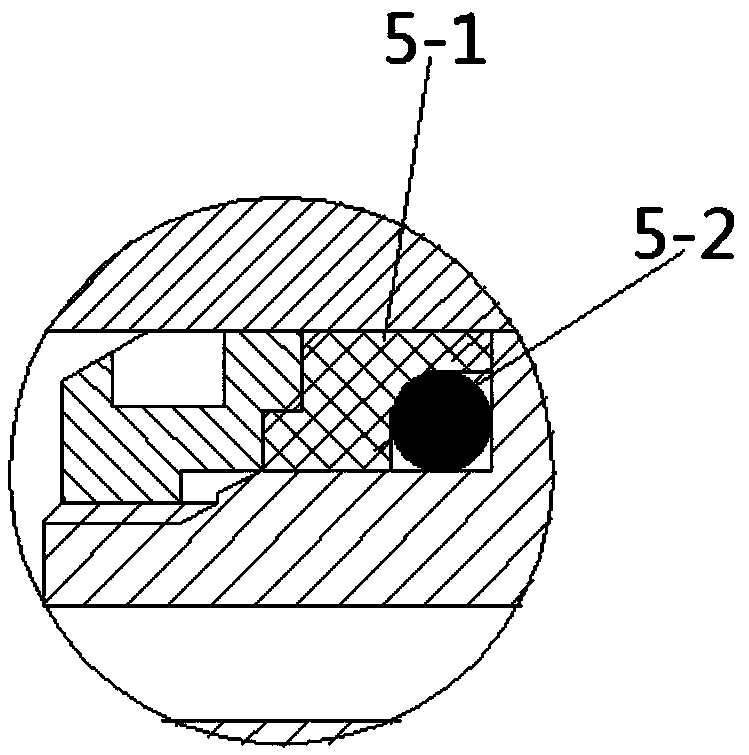

[0046] Such as Figure 4 , when the shock shaft 1 is pulled up, the pressure in the high-pressure chamber rises, the hydraulic oil pushes the sealing piston 4 to move, and the sealing piston 4 pushes the push sleeve 3 to move. At this time, the push sleeve 3 is subjected to the elastic member 2 in the shock shell 6 Active force, so the greater the force of the elastic member 2, the higher the pressure in the high-pressure chamber. When the shock shaft 1 moves to a certain position, the pressure in the high-pressure chamber is released, and there is a process of pressure balance on both sides, which produces a sudden change in pressure. The vibration shaft 1 is connected with the vibration hammer 7, and the middle is sealed by a second O-ring. The shock shaft 1 and the shock housing 7 are sealed by a first O-ring. The vibration hammer 7 and the vibration shell 6 are sealed by a combined sealing ring, and the combined sealing ring is arranged between the vibration hammer 7 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com