Process for producing bio-based nylon 56 fiber with antibacterial function

A technology of bio-based nylon and production process, which is applied in the field of fiber processing, can solve the problems of inconvenience for staff, inconvenient for staff to wear or use, and reduce the market popularity of bio-based nylon 56 fiber, so as to improve blood vessel circulation, good The effect of antibacterial ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

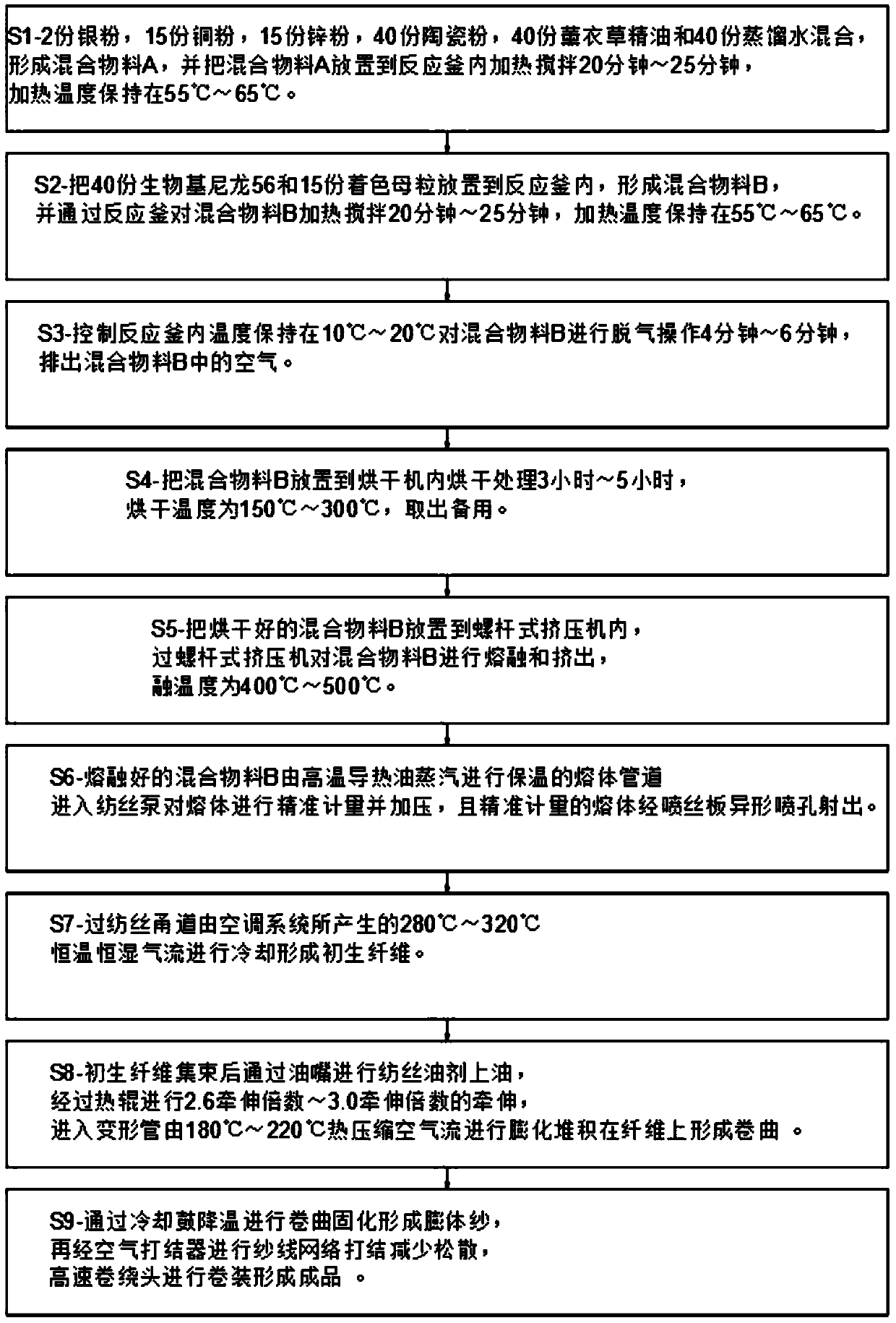

Image

Examples

Embodiment 1

[0028] A bio-based nylon 56 fiber with antibacterial function, which is composed of the following materials in proportion: 30 parts of bio-based nylon 56, 10 parts of coloring masterbatch, 30 parts of distilled water, 1 part of silver powder, 10 parts of copper powder, 10 parts Zinc powder, 30 parts ceramic powder, 30 parts lavender essential oil.

[0029] A manufacturing process, comprising the steps of:

[0030] S1-Mix 1 part of silver powder, 10 parts of copper powder, 10 parts of zinc powder, 30 parts of ceramic powder, 30 parts of lavender essential oil and 30 parts of distilled water to form a mixture A, and place the mixture A into the reactor for heating and stirring for 20 Minutes, the heating temperature is kept at 55°C;

[0031] S2-Put 30 parts of bio-based nylon 56 and 10 parts of colored masterbatch into the reactor to form a mixture B, and heat and stir the mixture B through the reactor for 20 minutes, and the heating temperature is kept at 55°C;

[0032] S3-Co...

Embodiment 2

[0042] A bio-based nylon 56 fiber with antibacterial function, which is composed of the following materials in proportion: 40 parts of bio-based nylon 56, 15 parts of coloring masterbatch, 40 parts of distilled water, 2 parts of silver powder, 15 parts of copper powder, 15 parts Zinc powder, 40 parts ceramic powder, 40 parts lavender essential oil.

[0043] A manufacturing process, comprising the steps of:

[0044] S1-Mix 2 parts of silver powder, 15 parts of copper powder, 15 parts of zinc powder, 40 parts of ceramic powder, 40 parts of lavender essential oil and 40 parts of distilled water to form a mixture A, and place the mixture A into the reactor for heating and stirring for 23 Minutes, the heating temperature is kept at 60°C;

[0045] S2- Put 40 parts of bio-based nylon 56 and 15 parts of colored masterbatch into the reactor to form a mixture B, and heat and stir the mixture B through the reactor for 23 minutes, and the heating temperature is kept at 60°C;

[0046] S3...

Embodiment 3

[0056] A bio-based nylon 56 fiber with antibacterial function, which is composed of the following materials: 50 parts of bio-based nylon 56, 20 parts of coloring masterbatch, 50 parts of distilled water, 3 parts of silver powder, 20 parts of copper powder, 20 parts Zinc powder, 50 parts ceramic powder, 50 parts lavender essential oil.

[0057] A manufacturing process, comprising the steps of:

[0058] S1-Mix 3 parts of silver powder, 20 parts of copper powder, 20 parts of zinc powder, 50 parts of ceramic powder, 50 parts of lavender essential oil and 50 parts of distilled water to form a mixture A, and place the mixture A into the reactor for heating and stirring for 25 Minutes, the heating temperature is kept at 65°C;

[0059] S2-Put 50 parts of bio-based nylon 56 and 20 parts of colored masterbatch into the reactor to form a mixture B, and heat and stir the mixture B through the reactor for 25 minutes, and the heating temperature is kept at 65°C;

[0060] S3-Control the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com