Engineering strain for producing high-molecular-weight hyaluronic acid, construction method thereof and application of engineering strain in producing high-molecular-weight hyaluronic acid

A technology of hyaluronic acid and construction methods, applied in the field of genetic engineering and microbes, can solve problems such as lack, and achieve the effect of simple composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] Example 1 BH-2 strain construction

[0102] The method of obtaining BH-2 is as follows:

[0103] 1) From the synthetic bacteria (synthesized by Genewiz) containing hyaluronan synthase (hyaluronan synthase, HAS), the hyaluronic acid was obtained by genome extraction (brand: Axygen product number: AP-MN-BT-GDNA-250G) and PCR method The acid synthase gene hasA sequence A, the sequence is shown in SEQ ID NO: 9, the PCR primer pair is hasABC-F1 / hasABC-R1, the sequence is shown in SEQ ID NO: 1 and SEQ ID NO: 2; the genome is extracted from Bacillus subtilis WB600, And the UDP-glucose dehydrogenase gene hasB sequence B is amplified by PCR method, the sequence is shown in SEQ ID NO: 14; the UDP-glucose pyrophosphorylase gene hasC sequence C is shown in SEQ ID NO: 15, and the PCR primer pairs are respectively For hasABC-F2 / hasABC-R2, see SEQ ID NO: 3 and SEQ ID NO: 4 for the sequence; for hasABC-F3 / hasABC-R3, see SEQ ID NO: 5 and SEQ ID NO: 6 for the sequence

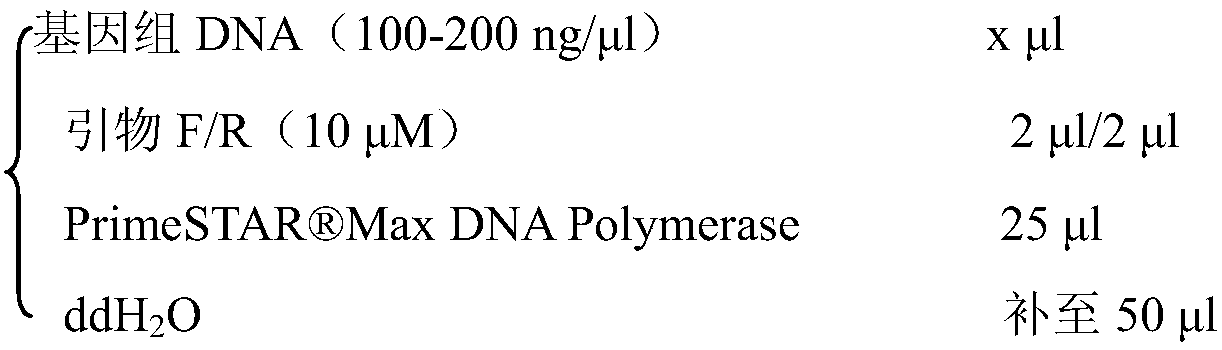

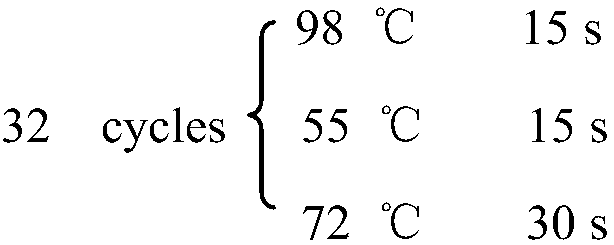

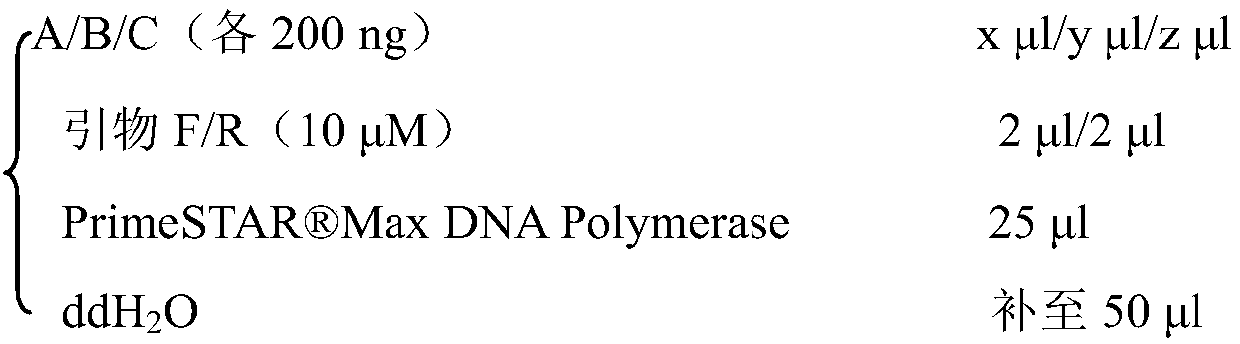

[0104] PCR reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com