BAHPFP silicon-containing adhesive and preparation method thereof

A technology of adhesives and organic solvents, applied in the direction of adhesives, etc., can solve the problems of high cost, high price, and unfavorable large-scale application of polyetherimide resins, and achieve industrial production, convenient operation, and good market application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

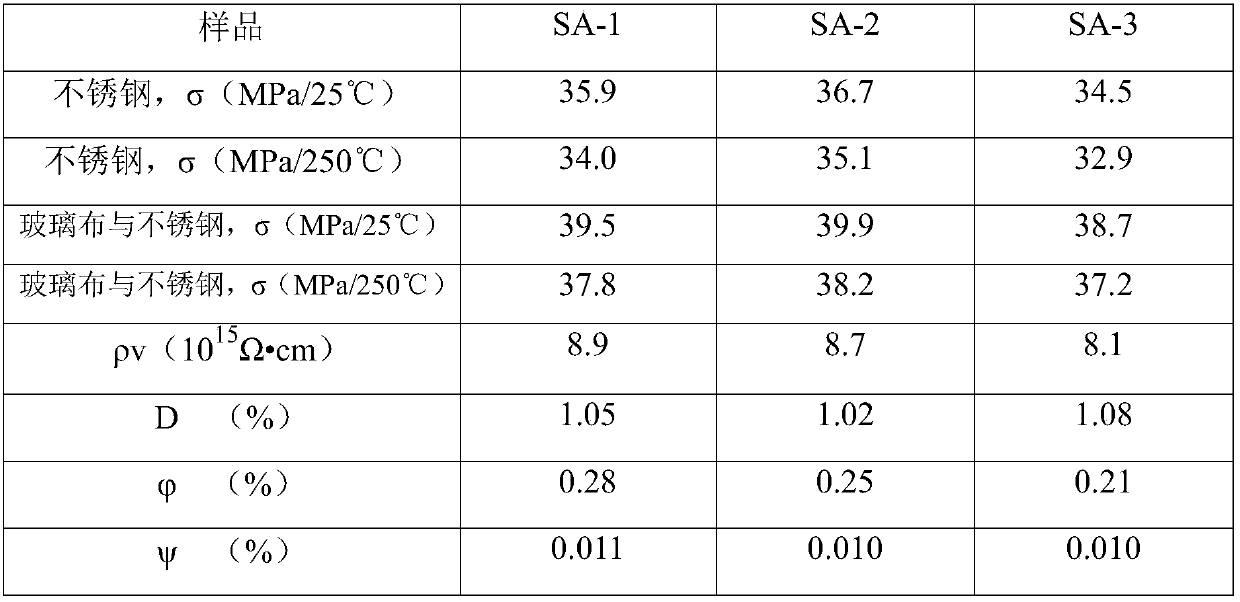

Embodiment 1

[0040] Put 36.6 grams (0.1 moles) of 2,2-bis(3-amino-4-hydroxyphenyl) hexafluoropropane (BAHPFP) and 1290 grams of N,N dimethylformamide into the reaction kettle and stir at room temperature After dissolving, add 40.0 g (0.1 mol) of 4,4'-bis(4-aminophenoxy) diphenyl sulfide, 60.0 g (0.3 mol) of 3,4'-diaminodiphenyl ether and 41.0 g (0.1 moles) 2,2-bis[4-(3-aminophenoxy)phenyl]propane, after stirring and dissolving, add 209.3 grams (0.65 moles) of 3,3',4,4'-tetracarboxybenzophenone Dianhydride, stirring and dissolving at room temperature, after stirring and reacting for 1.0 hour, add 22.1 grams (0.1 moles) of 3-aminopropyltriethoxysilane, stir and react at room temperature for 2 hours, then add 23.6 grams (0.1 moles) of γ-( 2,3-Glycidoxy)propyltrimethoxysilane was stirred and reacted at 80°C for 15 minutes to obtain 1722.6 grams of viscous, transparent and homogeneous BAHPFP-type silicone-containing adhesive, which was designated as SA-1.

Embodiment 2

[0042] 36.6 g (0.1 mol) of 2,2-bis(3-amino-4-hydroxyphenyl)hexafluoropropane (BAHPFP), 2000 g N,N dimethylacetamide and 960 g N-ethyl-2 - Pyrrolidone was put into the reaction kettle, stirred and dissolved at room temperature, 44.8 grams (0.2 moles) of 2-(4-aminophenyl)-5-aminobenzimidazole, 120.0 grams (0.6 moles) of 3,4'-bis Aminodiphenyl ether, 51.8 g (0.1 mol) 2,2-bis[4-(4-aminophenoxy)phenyl]hexafluoropropane and 40.0 g (0.1 mol) 4,4'-bis(4-amino Phenoxy) diphenyl sulfide, after stirring and dissolving, add 186.0 grams (0.6 moles) of 3,3',4,4'-tetracarboxy diphenyl ether dianhydride and 193.2 grams (0.6 moles) of 3,3',4 , 4'-tetracarboxybenzophenone dianhydride, stirring and dissolving at room temperature, after stirring for 4.0 hours, add 44.2 grams (0.2 moles) of 3-aminopropyltriethoxysilane, stirring and reacting at room temperature for 0.5 hours, then Add 23.6 grams (0.1 moles) of γ-(2,3-glycidyloxy)propyltrimethoxysilane, stir and react at 90°C for 15 minutes to obt...

Embodiment 3

[0044] 36.6 g (0.1 mole) of 2,2-bis(3-amino-4-hydroxyphenyl)hexafluoropropane (BAHPFP), 4200 g N,N dimethylformamide and 1600 g N-ethyl-2 -The organic solvent of pyrrolidone is put into the reaction kettle, after stirring and dissolving at room temperature, add 160.0 grams (0.4 moles) of 4,4'-bis(4-aminophenoxy) diphenyl sulfide and 60.0 grams (0.3 moles) of 3 ,4'-diaminodiphenyl ether, after stirring and dissolving, add 225.4 grams (0.7 moles) of 3,3',4,4'-tetracarboxybenzophenone dianhydride, 78.0 grams (0.15 moles) of 2,2- Bis[4-(3,4-dicarboxyphenoxy)phenyl]propane dianhydride was stirred and dissolved at room temperature, and after stirring for 2.0 hours, 22.1 grams (0.1 mole) of 3-aminopropyltriethoxysilane was added And 17.9 grams (0.1 moles) of 3-aminopropyltrimethoxysilane, stirred at room temperature for 1.5 hours, then added 47.2 grams (0.2 moles) of γ-(2,3-epoxypropoxy)propyltrimethoxysilane , stirred and reacted at 85°C for 15 minutes to obtain 6447.2 grams of vis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com