A kind of high temperature resistant acid and alkali resistant acrylate pressure sensitive adhesive composition and protective film

A technology of acrylate and pressure-sensitive adhesives, applied in the direction of pressure-sensitive films/sheets, ester copolymer adhesives, non-polymer adhesive additives, etc., which can solve the problems of high cost, low production efficiency, and inability to meet simultaneously , to achieve high transparency and increase the effect of cross-linking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

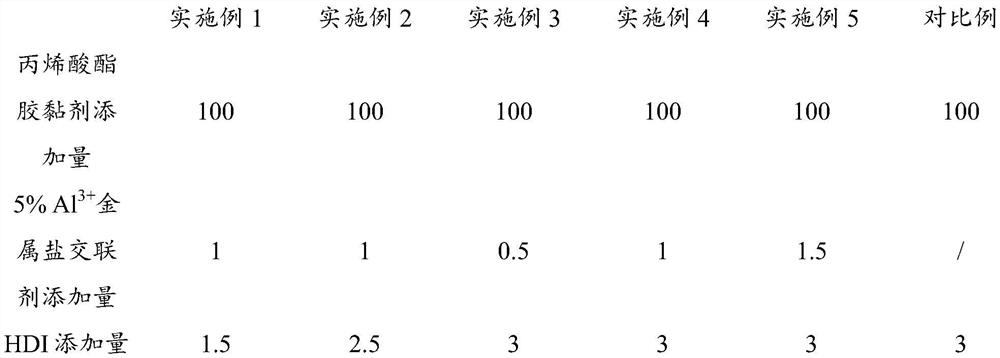

Embodiment 1

[0022] 100g of the acrylate adhesive prepared above, 1g of 5% Al 3+ Add metal salt crosslinking agent, 1.5g hexamethylene diisocyanate, 10g toluene and 90g ethyl acetate into the container with stirring device, and stir thoroughly for 30 minutes. After the bubbles disappear, filter with a filter of ≤5 μm to remove impurities to prepare an acrylate pressure-sensitive adhesive composition.

Embodiment 2

[0024] 100g of the acrylate adhesive prepared above, 1g of 5% Al 3+ Add metal salt crosslinking agent, 2.5g hexamethylene diisocyanate, 10g toluene and 90g ethyl acetate into the container with stirring device, and stir thoroughly for 30 minutes. After the bubbles disappear, filter with a filter of ≤5 μm to remove impurities to prepare an acrylate pressure-sensitive adhesive composition.

Embodiment 3

[0026] 100g of the acrylate adhesive prepared above, 0.5g of 5% Al 3+ Add metal salt crosslinking agent, 3g hexamethylene diisocyanate, 10g toluene and 90g ethyl acetate into the container with stirring device, and stir thoroughly for 30 minutes. After the bubbles disappear, filter with a filter of ≤5 μm to remove impurities to prepare an acrylate pressure-sensitive adhesive composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com