Polyurethane adhesive for high-cohesiveness popcorn sole and preparation method thereof

A technology of polyurethane adhesive and high cohesiveness, which is applied in the field of polyurethane synthesis, can solve the problems that are not related to the synthesis method, synthesis process, and performance parameters of the foaming adhesive, so as to improve chemical stability and improve Void, the effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

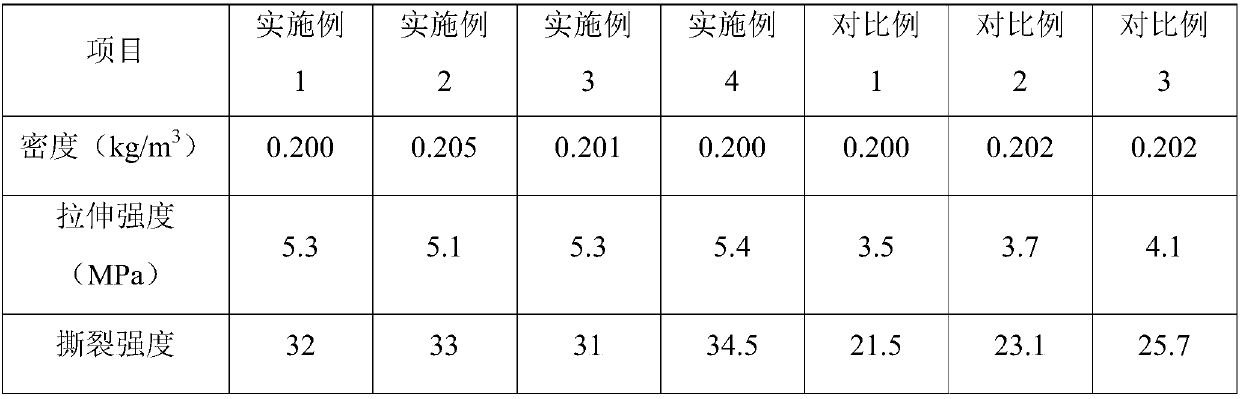

Embodiment 1

[0034] Put 70kg DL4000 into the stirring tank at room temperature, start the stirring, the speed is 100r / min, heat up to 105°C, vacuumize, the vacuum degree is lower than -0.095MPa, dehydrate and degas for 2 hours, check the moisture, lower than 5 / 10,000, cool down To 40°C, add 20kg of NDI isocyanate and 3g of phosphoric acid, heat up to 85°C, react for 2 hours, then add 0.2kg of nano-titanium dioxide, continue to keep warm for 1 hour, finally add 10kg of DOTP, stir for 30 minutes to sample, after passing the test, cool down to room temperature , Nitrogen-sealed barrels.

Embodiment 2

[0036] Add 65kgED-28 to the stirring tank at room temperature, start stirring, rotate at 80r / min, heat up to 110°C, vacuumize, the vacuum degree is lower than -0.095MPa, dehydrate and degas for 2 hours, check the moisture, it is less than 5 / 10,000, Cool down to 30°C, add 20kg of NDI isocyanate and 3g of phosphoric acid, heat up to 85°C, react for 1 hour, then add 1.0kg of nano-calcium phosphate, keep warm for 2 hours, finally add 15kg of DOP, stir for 30 minutes to sample, after passing the test, cool down To room temperature, nitrogen sealed barrels.

Embodiment 3

[0038] Put 25kgEP-3600 and 50kgDL3000 into the stirring tank at room temperature, start stirring, the speed is 90r / min, heat up to 100°C, vacuumize, the vacuum degree is lower than -0.095MPa, dehydrate and degas for 2 hours, check the moisture, it is lower than 10000 5. Cool down to 35°C, add 15kg of pure MDI, 5kg of liquefied MDI and 3g of benzoyl chloride, heat up to 70°C, react for 2 hours, then add 0.5kg of nano-dicalcium phosphate, continue to keep warm for 1 hour, and finally add 5kg of DBP, Stir for 45 minutes to take a sample. After passing the test, cool down to room temperature and pack in a nitrogen-tight barrel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com