Adjustable suspension type surface cleaning device for household appliance castings

A household appliance product and surface cleaning technology, which is applied in the direction of used abrasive processing devices, abrasives, metal processing equipment, etc., can solve problems such as troublesome, inability to clean dead corners, etc., to improve cleaning effect, improve cleaning efficiency, and increase contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

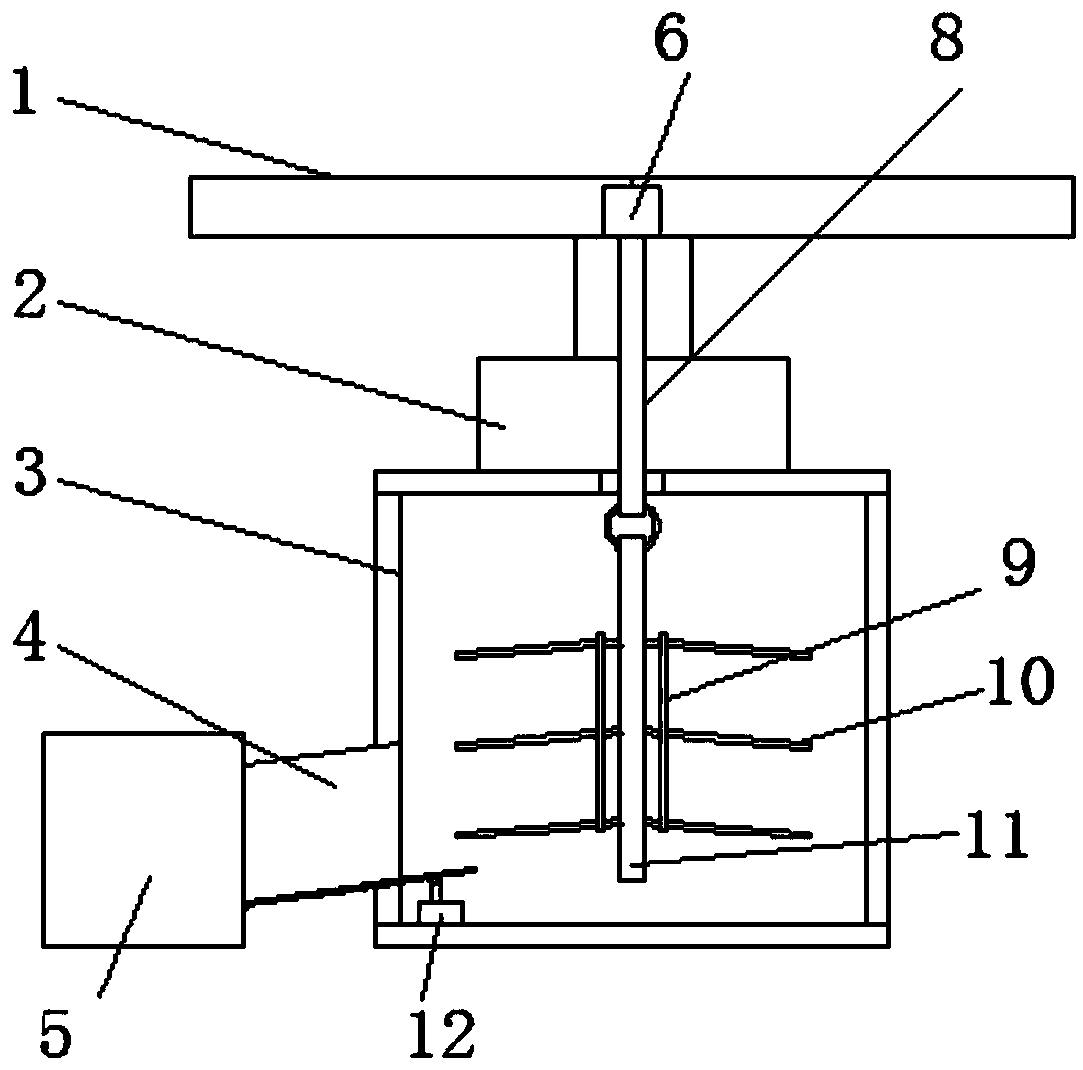

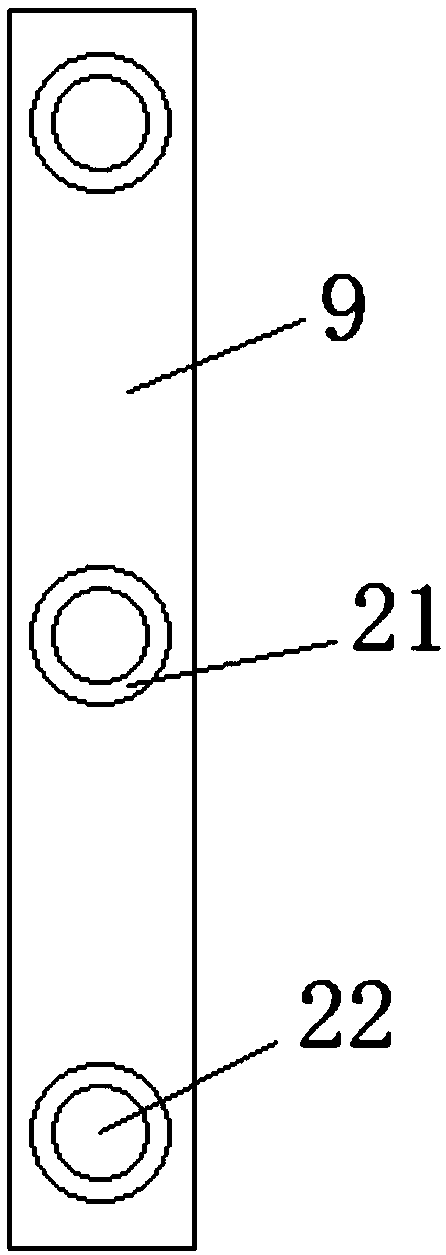

[0024] Embodiment 1, an adjustable suspension type surface cleaning device for castings of household appliances, including a shot blasting chamber 3, a conveying rail 1, a support block 2, a hook 8 and a shot blasting machine 5, and the upper end of the shot blasting chamber 3 is provided with There is a support block 2, the upper end of the support block 2 is provided with a symmetrically distributed slide rail 1, the slide rail 1 is provided with a slider 6, the bottom of the slider 6 is provided with a hook 8, and the shot blasting chamber 3 A shot blasting machine 5 is provided on one side, and the shot blasting machine 5 communicates with the shot blasting chamber 3 through the connecting pipe 4. The bottom of the hook 8 is provided with a clamping fixed column 11, and the fixed column 11 is from top to bottom A number of uniform and center-symmetrically distributed adjustment grooves 7 are provided, and the bottom of the adjustment grooves 7 is provided with a movable con...

Embodiment 2

[0027] The same as embodiment 1 is no longer repeated, and the difference with embodiment 1 is:

[0028] Preferably, the middle part of the fixed rod 11 is provided with a first adjustment hole 18, the first adjustment hole 18 is provided with a matching first adjustment rod 13, and the fixed rod 11 is provided with several sets of symmetrically distributed The second adjustment hole 27, the second adjustment hole 27 is connected with the first adjustment hole 18, the second adjustment hole 27 is provided with a matching second adjustment rod 15, and the second adjustment hole 27 is provided with There is a second connecting rod 16, the two ends of the second connecting rod 16 are provided with second living hinges 28, and the second living hinges 28 at both ends of the second connecting rod 16 are respectively connected with the corresponding first adjusting rod 13 and the first adjusting rod 13. The two adjustment rods 15 are connected, and the upper end of the first adjustm...

Embodiment 3

[0032] The same as embodiment 2 will not be repeated, and the difference with embodiment 1 is:

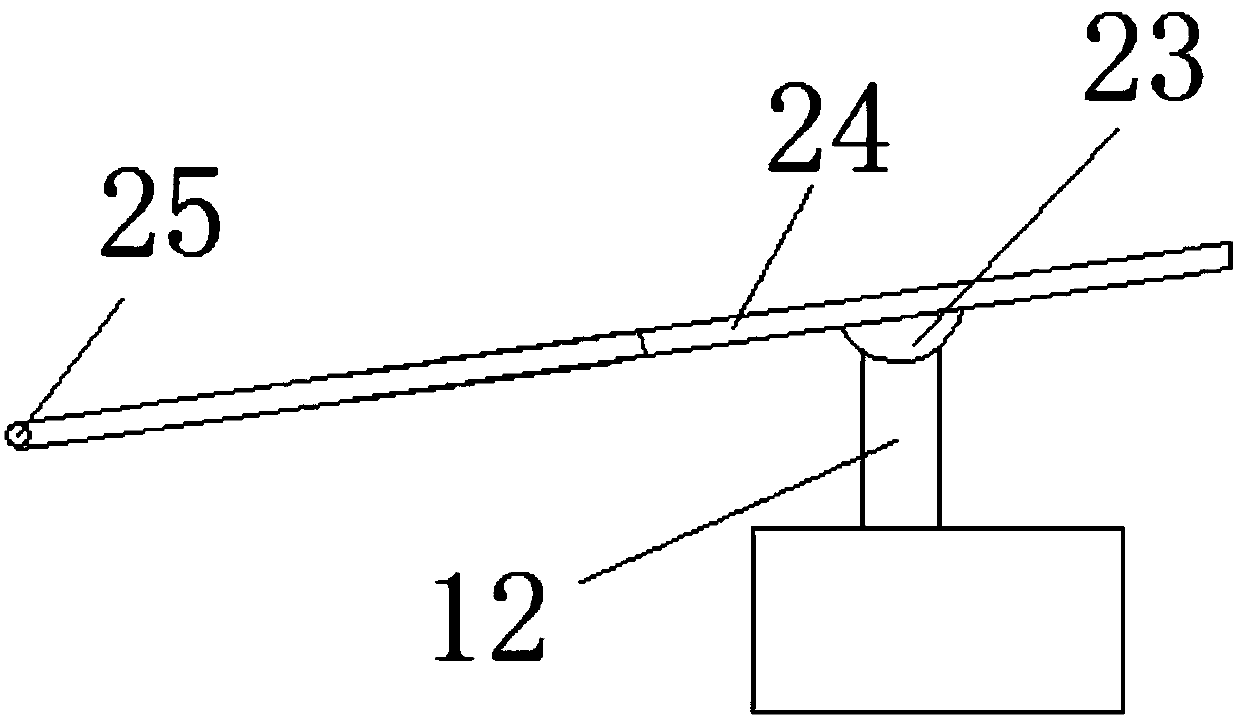

[0033] Preferably, the adjustment plate 24 is a telescopic adjustment plate, and the front end of the adjustment plate 24 is arranged at the bottom of the outer side of the fixed rod 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com