Welding method of photovoltaic assembly junction box

A welding method and technology of photovoltaic modules, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of easy occurrence of false welding and hidden safety hazards, so as to improve welding firmness and reduce false welding chance, the effect of reducing the chance of false welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] The invention provides a welding method for a junction box of a photovoltaic module, the welding method comprising the following steps:

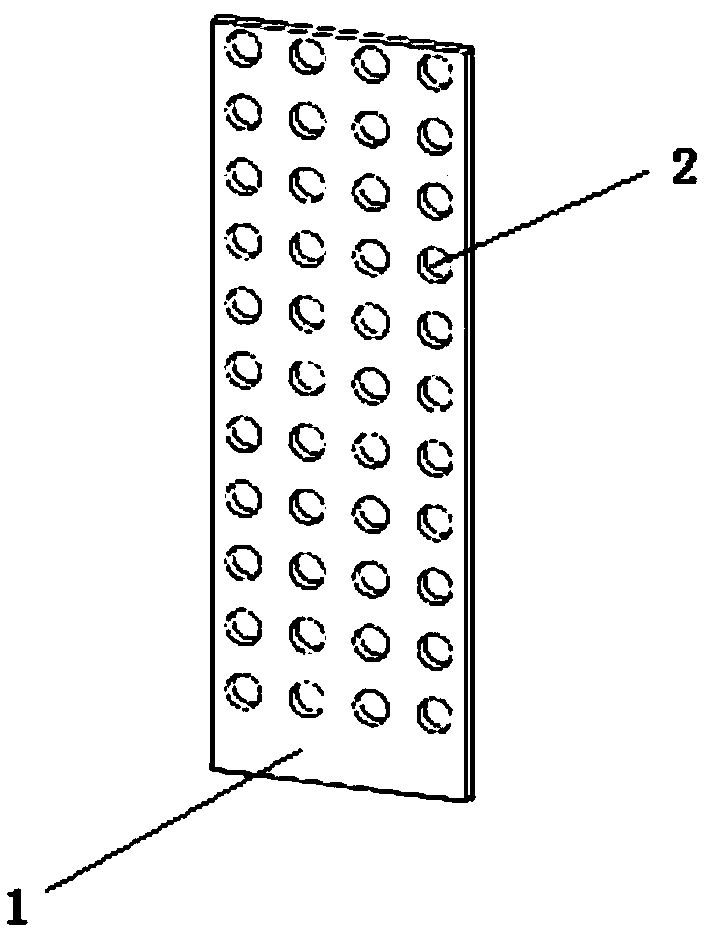

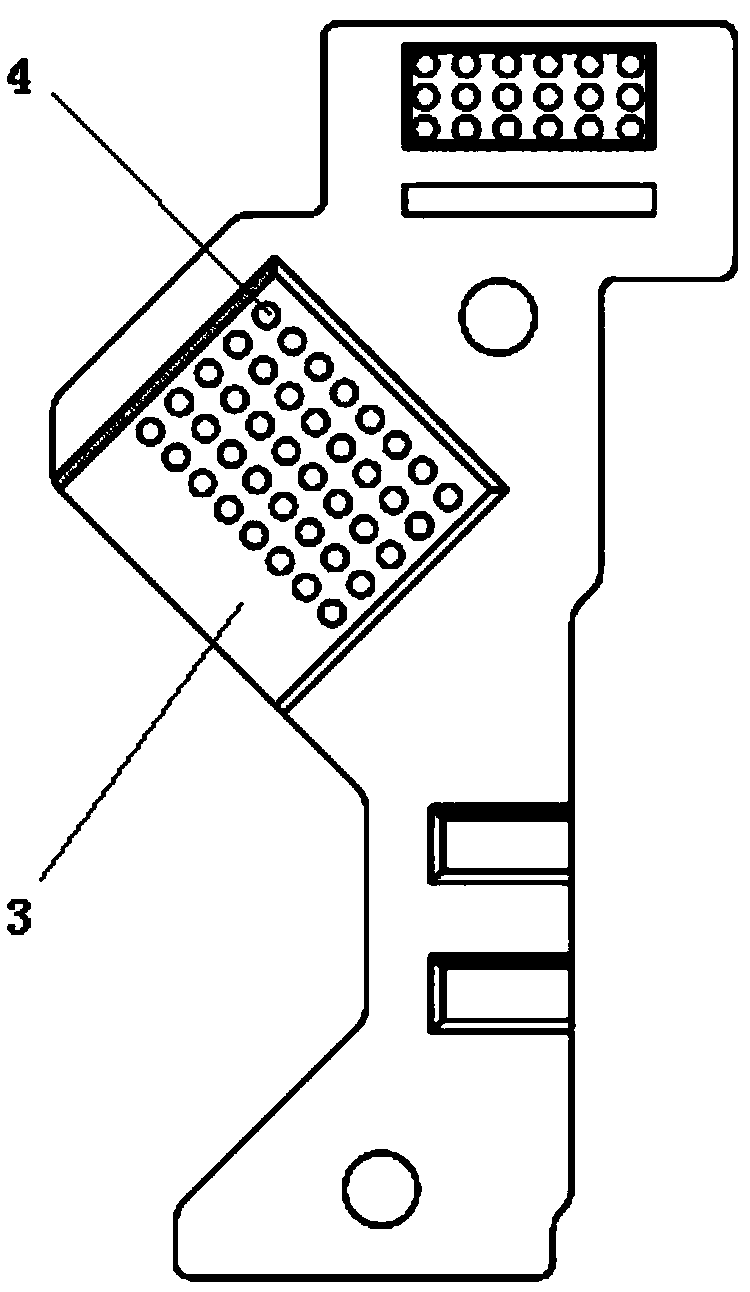

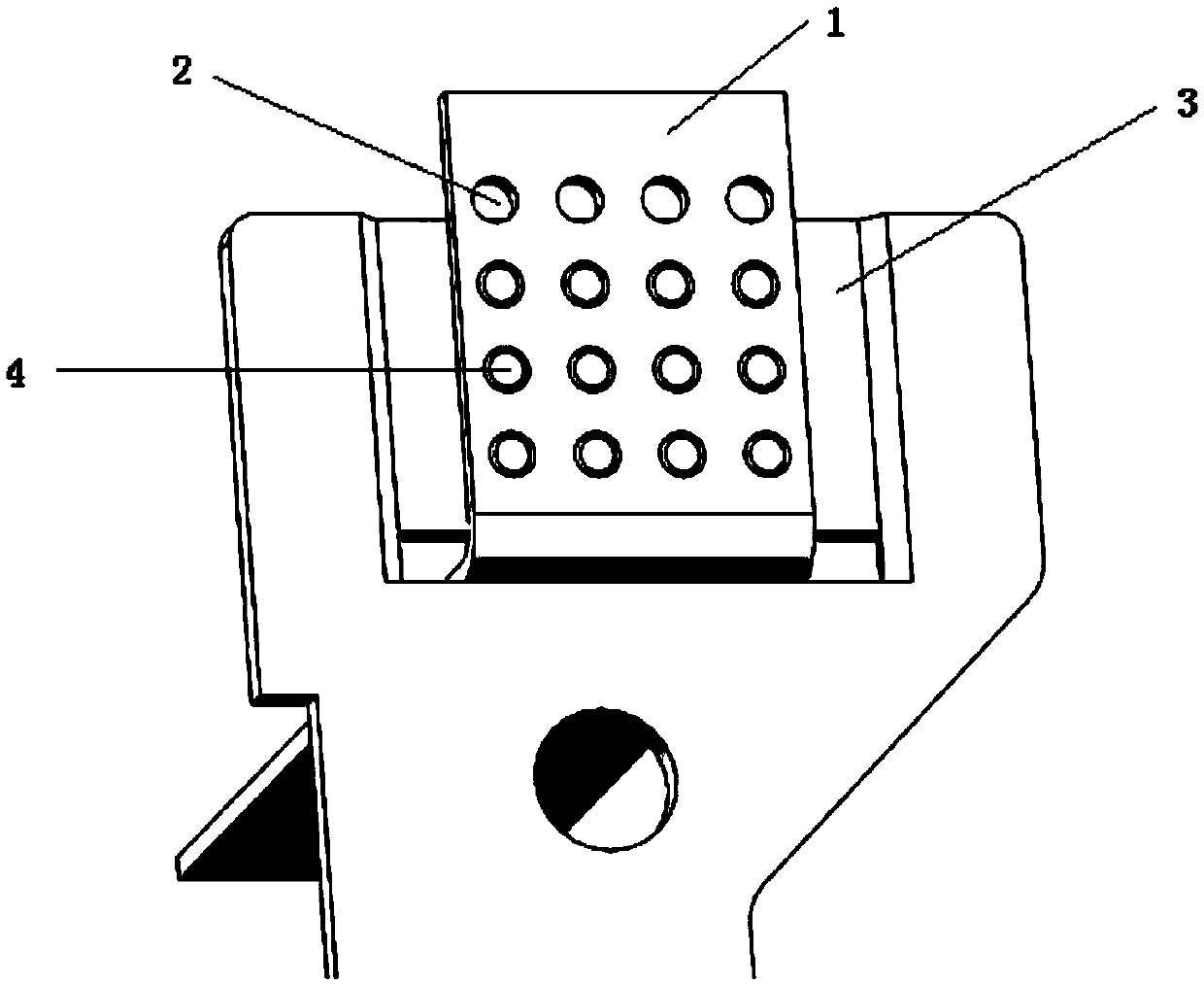

[0023] Step S1, providing a bus bar 1 with a through hole 2 and a junction box pad 3 with a columnar protrusion 4;

[0024] Step S2, insert the columnar protrusion 4 into the through hole 2 on the bus bar 1, heat the solder on the surface of the bus bar 1 to melt, and make the melted solder enter between the through hole 2 of the bus bar 1 and the columnar protrusion 4, The molten solder is then allowed to condense.

[0025] The bus bar is a metal connector that collects the current of the battery string in the photovoltaic module and connects it to the junction box of the module. There is a layer of solder (that is, solder made of tin-based alloy) on the surface of the bus bar. After the solder is heated to a certain temperature, it can molten.

[0026] In the welding method provided by the present invention, the columnar protrusio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com