Technological method for hot stamping forming manufacturing of automobile part through medium-thickness boron alloy steel sheet

A technology for hot stamping and auto parts, which is used in the field of hot stamping of medium-thick sheets to manufacture auto parts, and can solve the problems that the application is not as wide and mature as that of thin-sheet parts, the metallographic structure is difficult to obtain, and the mechanical properties of parts are deteriorated. The effect of improving rapid cooling rate, overcoming technical obstacles, and ensuring design accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

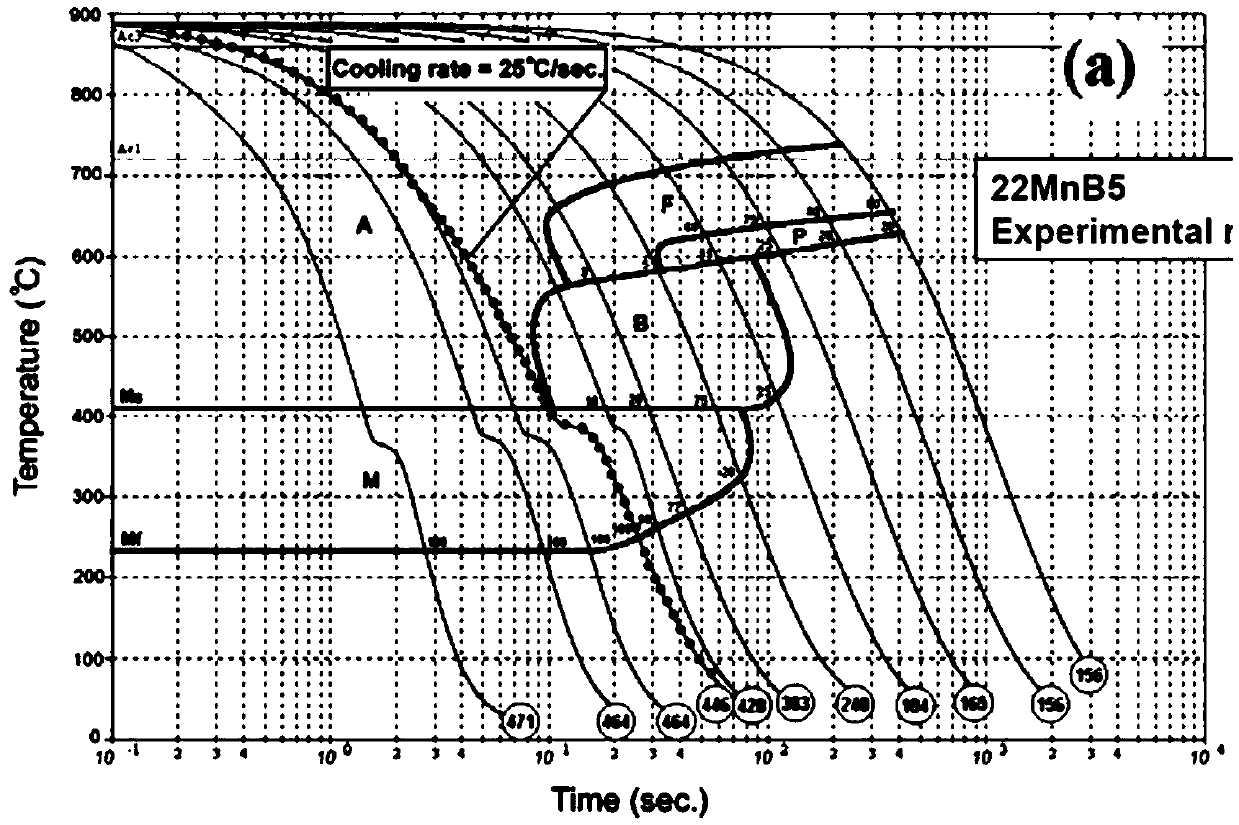

[0019] Material selection: In this embodiment, a boron alloy steel plate with a thickness of 6 mm is selected.

[0020] 1. Stamping and cutting blanks:

[0021] 2. The billet is heated in the furnace for austenitization: put the cut billet into the heating furnace with a furnace temperature of 950°C and heat it for 4 minutes to obtain a surface temperature of 950°C and a core temperature of more than 850°C. The metallographic structure is all austenitic Body blank;

[0022] The reason is as follows: For a steel plate with a thickness of 6mm, it takes 12 minutes to heat the steel plate from the inside to the outside to 950°C in the traditional process. When using this process, the 6mm thick steel plate can be heated at 950°C for 4 minutes to obtain the result that the surface is 950°C and the core is also greater than 850°C. At this time, it is guaranteed that the steel plate is completely austenitized. By this method, the temperature inside the steel plate is reduced by abou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com