Prestressed steel wire with small relaxation rate and manufacturing method of prestressed steel wire

A prestressed steel wire and manufacturing method technology, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems of inability to adjust the tension of the steel wire independently, low relaxation, etc., to achieve optimal tension effect, smooth belt line, and improve compression deformation volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

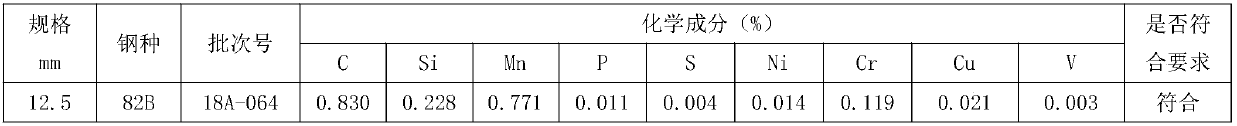

[0021] A φ7.50mm prestressed steel wire with small prestress relaxation value and stable performance. The innovation of the present invention is that the mass fractions of the main elements of the wire rod used in the production of the prestressed steel wire are: C: 0.80-0.85%, Si: 0.10- 0.30%, Mn: 0.60-0.90%, P: ≤0.025%, S: ≤0.025%, Ni: ≤0.10%, Cr: ≤0.35%, Cu: ≤0.2%, V: ≤0.15%, and the rest are Fe and Unavoidable impurity elements.

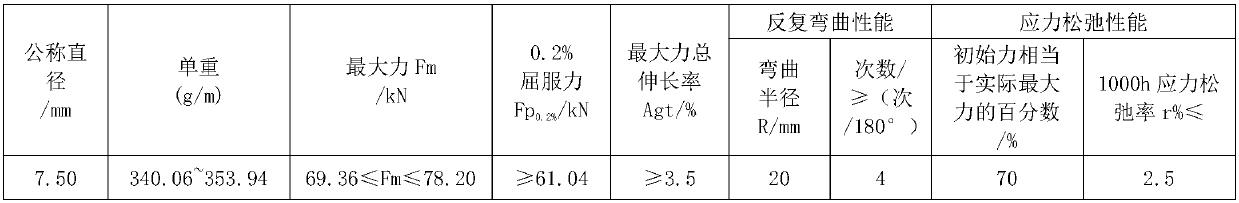

[0022] According to the requirements of the GB / T5223-2014 standard, the technical indicators of the prestressed steel wire are shown in Table 1.

[0023] Table 1 Performance requirements of φ7.50mm1570MPa grade prestressed steel wire

[0024]

[0025] Satisfying the technical indicators in Table 1 and havi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com