Device for separating waste concrete to manufacture sand, stone and silicate aluminate material

A technology for waste concrete and aluminosilicate, applied in solid waste management, sustainable waste treatment, cleaning methods and utensils, etc., can solve the problems of low energy consumption, low heat rate, emission, low efficiency, etc. Natural environment, solving the shortage of admixture sources, the effect of simple process and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

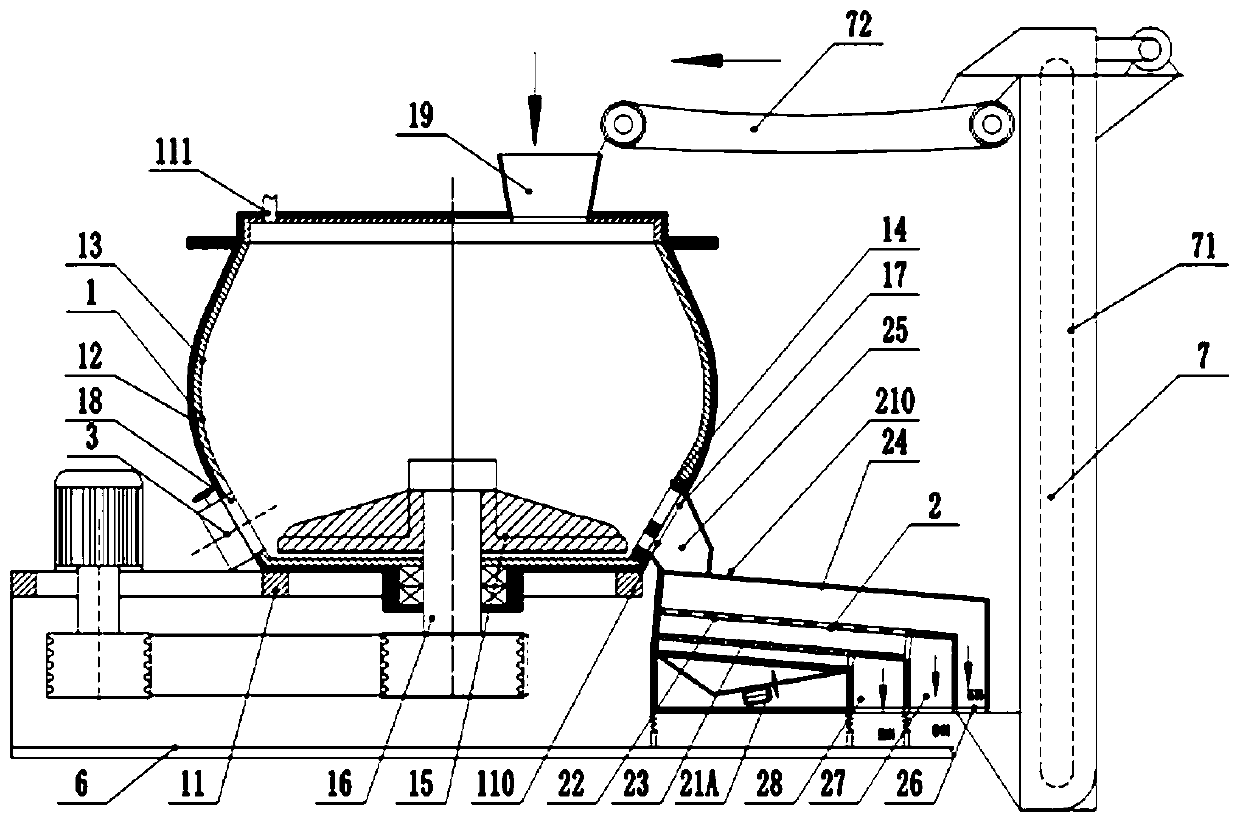

[0026] refer to figure 1 , this embodiment includes a disintegration repairing device 1, a separation device 2, an inspection and discharge mechanism 3, a high-pressure water system 5 and a bracket 6, and the mixing of the discharge port 110 of the disintegration repairing device 1 and the separation device 2 The material inlet 25 is connected, the maintenance and discharge mechanism 3 is fixed on the disintegrating material repairing device 1, the high-pressure water system 5 is connected with the disintegrating material repairing device 1 and the separation device 2 respectively, and the disintegrating repairing material The device 1 and the separation device 2 are fixed on the bracket 3 .

[0027] The disintegration and repairing device 1 described therein is a first-stage centrifugal impact grinding disintegration and repairing mechanism, and the first-stage centrifugal impact grinding disintegration and repairing mechanism mainly includes a bracket 11, a cylinder body 12,...

Embodiment 2

[0030] refer to figure 2 , this embodiment adopts the form of a dry-type primary disintegration and repairing material mechanism, mainly including a disintegration and repairing device 1, a separation device 2, an inspection and discharge mechanism 3, a power mechanism 4, a material circulation system 7 and a bracket 6, the described The discharge port 110 of the disintegrating material repairing device 1 is connected with the feed port 25 of the separation device 2, the maintenance and discharge mechanism 3 is fixed on the disintegrating material repairing device 1, and the inlet and outlet of the material circulation system 7 are respectively connected with the The stone discharge port 26 of the separation device 2 is connected to the feed port 19 of the disintegration and repair device 1; the disintegration and repair device 1, the separation device 2, and the material circulation system 7 are fixed on the support 3.

[0031] The disintegration and repairing device 1 descr...

Embodiment 3

[0033] refer to image 3 , this embodiment adopts three-stage wet disintegration and repair mechanism, including disintegration and repair mechanism 1, disintegration and repair mechanism 1IA, disintegration and repair mechanism II1B, separation device 2, maintenance and discharge mechanism 3, power mechanism 4, High pressure water system 5, support 6.

[0034] The disintegration and repairing mechanism 1, the disintegration and repairing mechanism 1IA, and the disintegration and repairing mechanism II1B constitute a disintegration and repairing device; the disintegration and repairing mechanism 1 mainly includes a bracket 11, a cylinder 12, a wear-resistant Lining plate 13, overflow grate plate 14, a wear-resistant impeller 15 throwing tray, main shaft 16, overflow hole 17, discharge port 18, feed port 19, discharge port 110, cylinder 12 is fixed on the bracket 11 Above, the wear-resistant liner 13 is fixed on the inner wall of the cylinder 12, the wall of the cylinder 12 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com