A system and method for comprehensive treatment and thermal energy utilization of coal chemical vocs

A comprehensive treatment and coal chemical technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., to achieve high energy utilization, save energy, and improve energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail through specific embodiments below in conjunction with schematic diagrams.

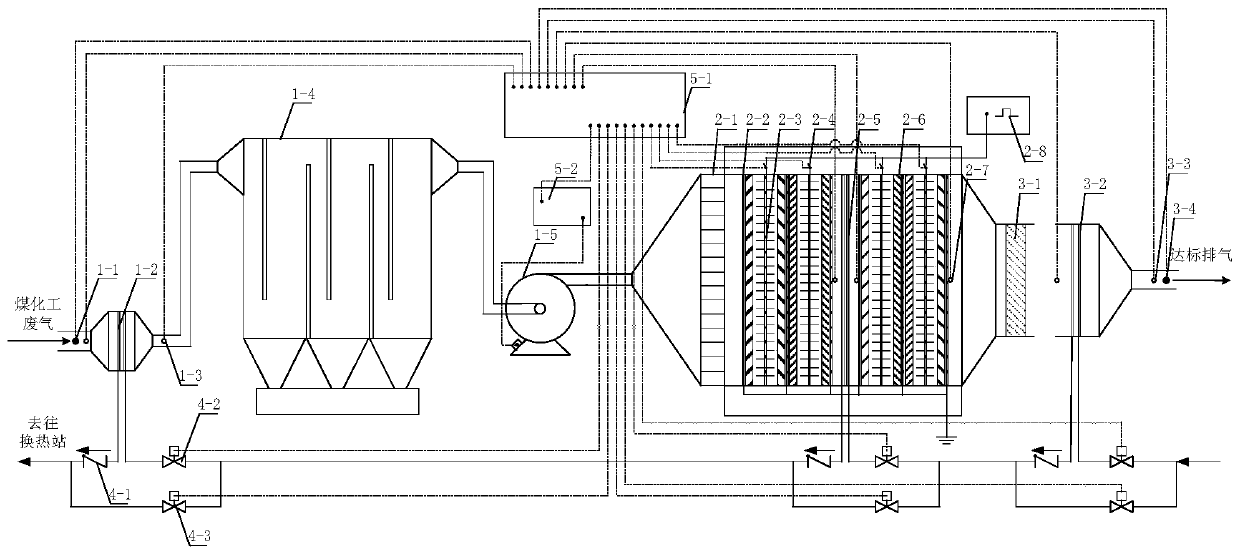

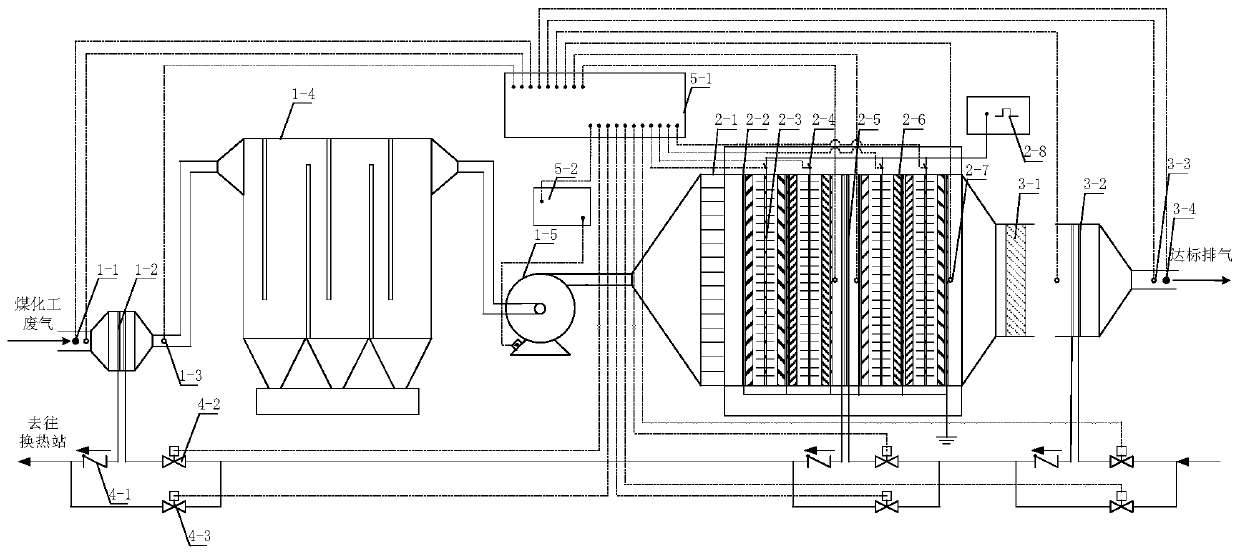

[0036] Such as figure 1 As shown, the present invention provides a coal chemical VOCs comprehensive treatment and thermal energy utilization system, including a gas pretreatment unit, a low-temperature plasma synergistic catalytic unit, an exhaust gas post-processing unit, a thermal energy recovery unit and a monitoring and control unit. Among them, the gas pretreatment unit is designed to remove the solid particles carried in the exhaust gas and pressurized by the fan; the low-temperature plasma synergistic catalytic unit uses the low-temperature plasma generated by gas discharge to activate the low-temperature catalytic oxidation reaction to oxidize and decompose VOCs into H 2 O.CO 2 and other harmless substances; the exhaust gas post-treatment unit uses a catalyst to reduce the possible O 3 Removal of harmful by-products, such as ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com