A chain energy consumption device and its control method

An energy-consuming device and a control method technology, applied in the field of chain energy-consuming devices and control, can solve the problems of equipment safety operation hazards, DC transmission line voltage rise, large voltage and current rate of change, etc., to reduce shutdown Risk of overvoltage, increased operational reliability, cost and volume reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with accompanying drawing.

[0040] In order to achieve the above object, the concrete scheme that the present invention adopts is as follows:

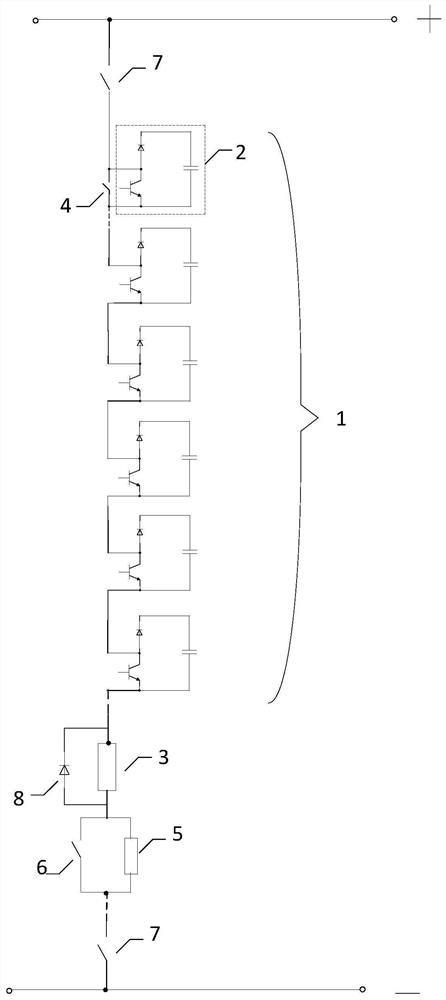

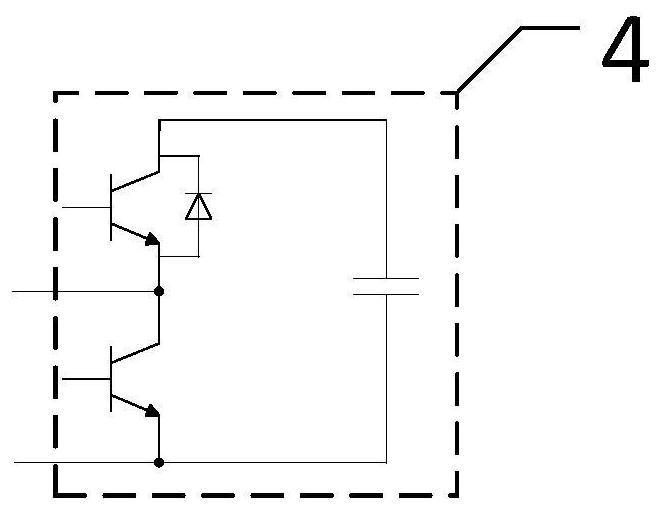

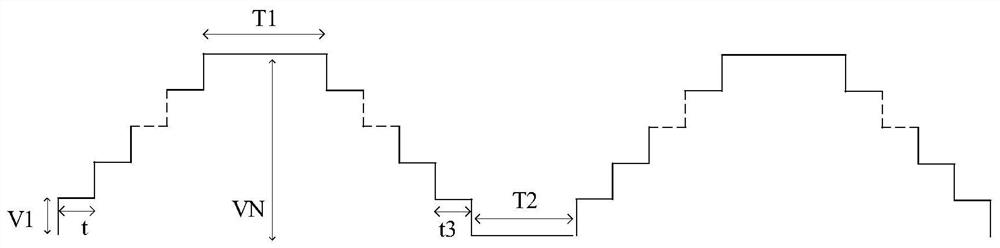

[0041] like figure 1 As shown, a chain type energy consumption device, the device is composed of an energy consumption branch 1 and an energy consumption resistor 3, the energy consumption branch is composed of at least one energy consumption sub-module 2 connected in series in the same direction, the series connection The first end of the energy dissipation resistor is connected to the high-potential electrode of the DC line; the energy dissipation resistor is centrally arranged and connected in series with the energy dissipation branch, one end of the energy dissipation resistor is connected to the tail end of the energy dissipation branch, and the other end is connected to the low potential electrode of the DC line. Electrode connection; the energy consump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com