SBH15-M sealed amorphous alloy power transformer

A technology of power transformers and amorphous alloys, which is applied in the field of power transformers, can solve the problems of speeding up the transformer oil entering the oil tank, accidental drop of the oil pot, and affecting the efficiency of oil replenishment, so as to reduce the probability of accidental spillage, easy to absorb and store, The effect of improving oil replenishment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

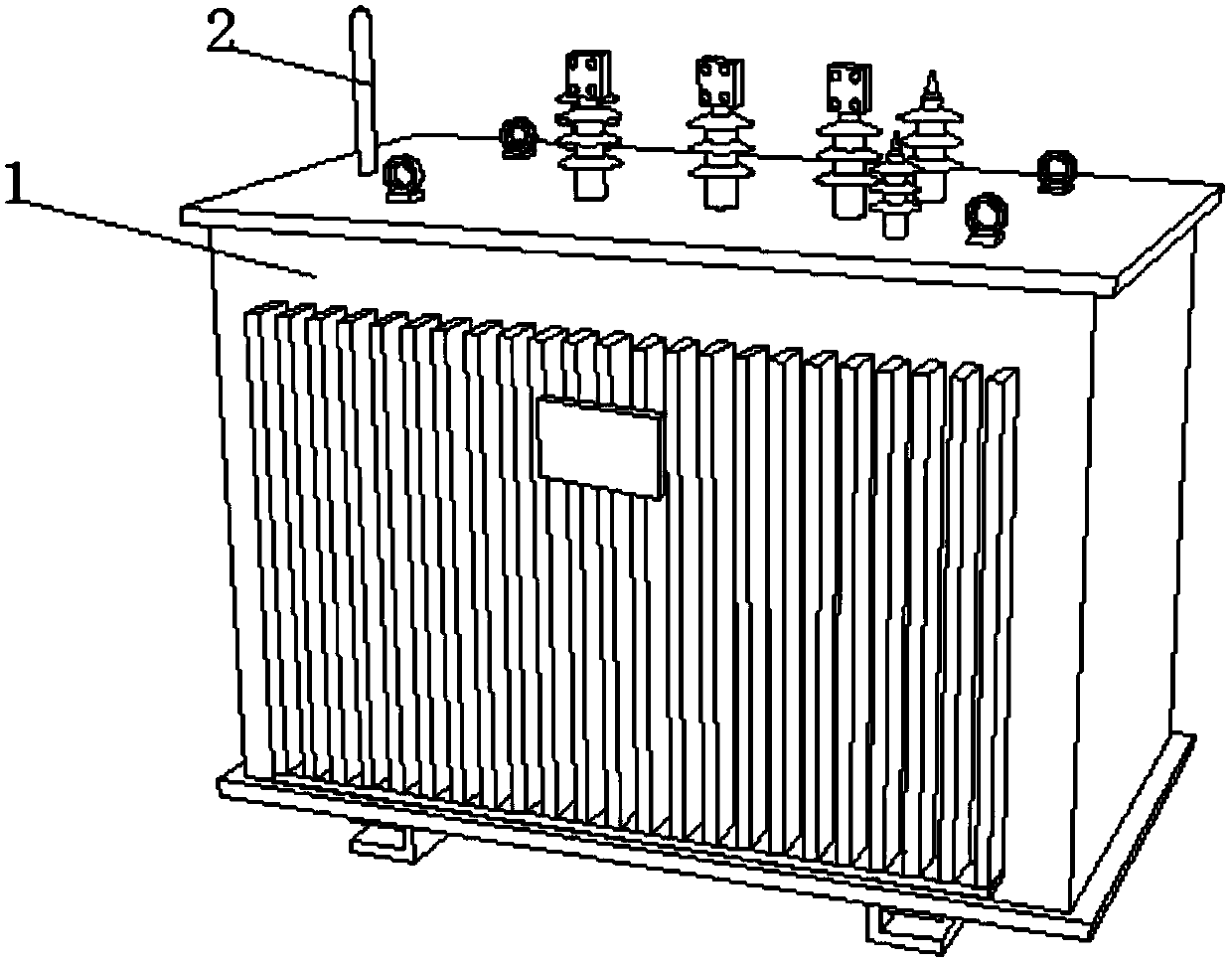

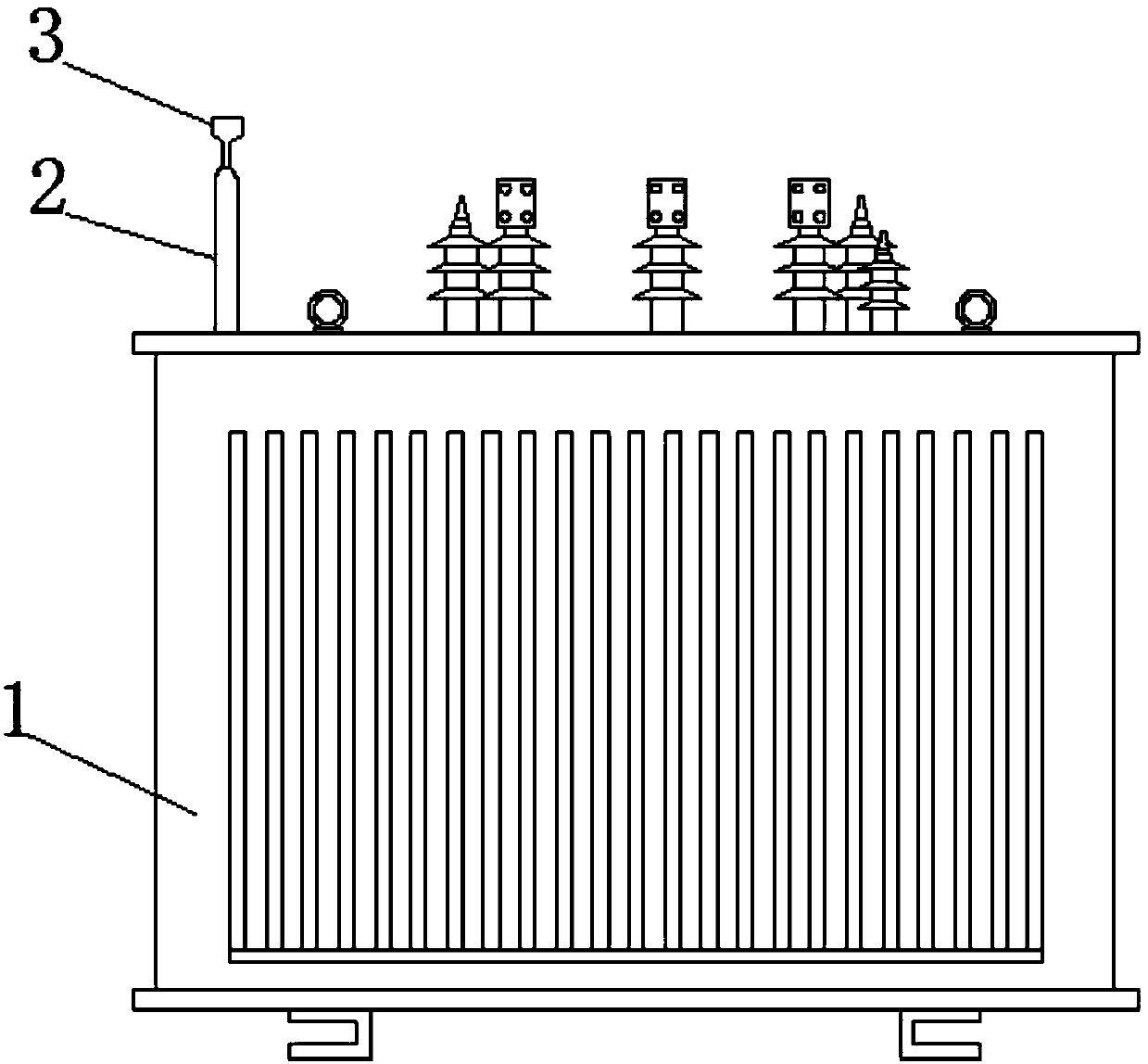

[0043] see Figure 1-2 , a SBH15-M sealed amorphous alloy power transformer, including a transformer body 1, an oil tank is installed at the inner end of the transformer body 1, an oil column 2 is installed at the upper left end of the transformer body 1, the oil column 2 communicates with the oil tank, and the inside of the oil column 2 A self-vibrating funnel 3 is inserted, and the bottom of the self-vibrating funnel 3 is flush with the oil replenishment target line on the oil column 2 .

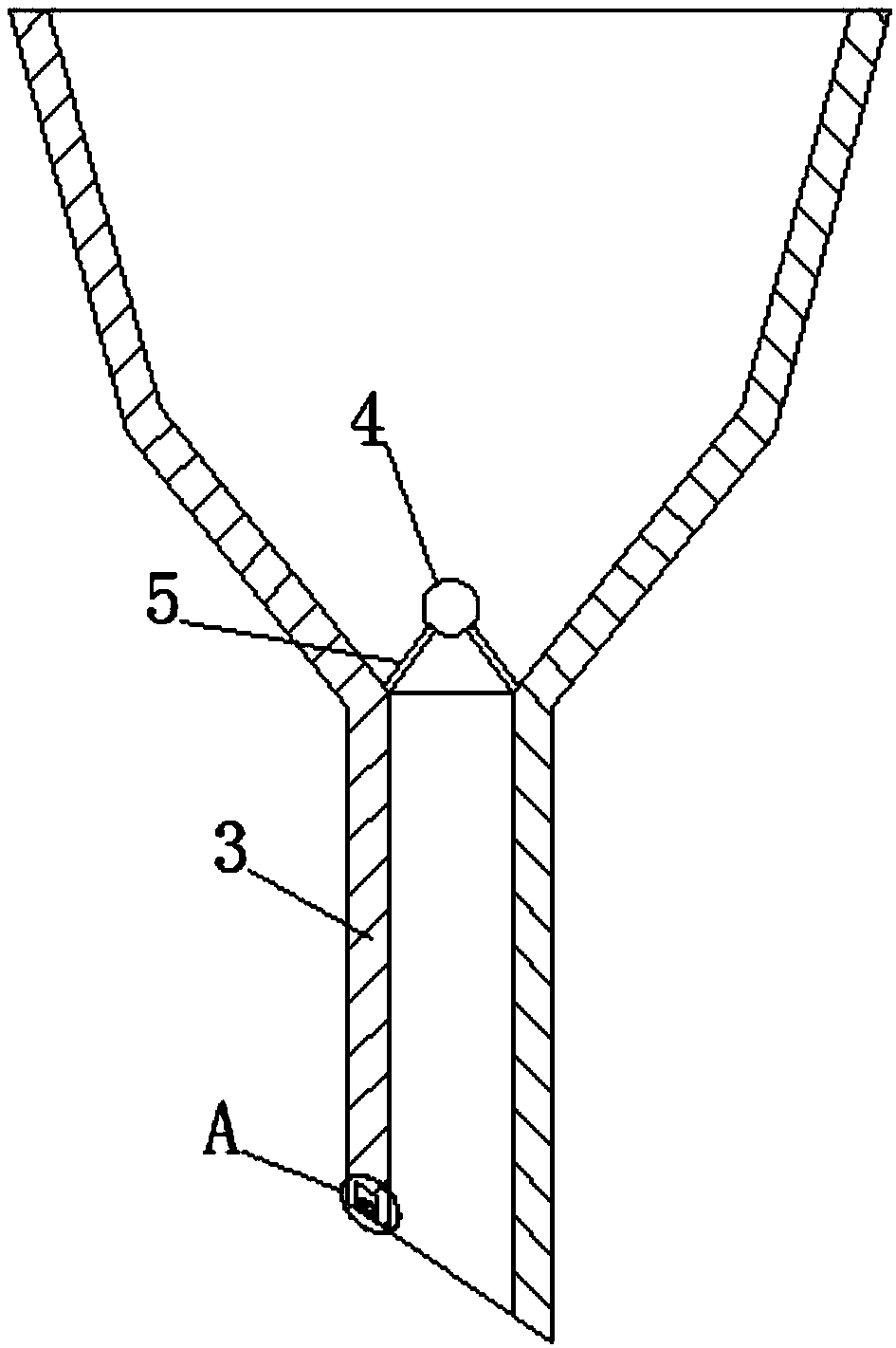

[0044] see Figure 3-4 , the self-vibrating funnel 3 includes a wide-mouth oil storage hopper and a fine-mouth oil leakage pipe, the wide-mouth oil storage hopper and the fine-mouth oil leakage pipe are fixedly connected, and the connection between the wide-mouth oil storage hopper and the fine-mouth oil leakage pipe is provided with a vibration four To the ball, there are three color inspection and sampling mechanisms at the bottom of the thin-mouth oil leakage pipe. The color inspection...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Section diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com