Biomass gas burner with adjustable flame length and using method thereof

A technology of biomass gas and flame length, which is applied in the direction of combustion method, burner, combustion type, etc., can solve the problems of poor quality of rotary flame heating, billet oxidation and burning of nitrogen oxides, flame length can not be flexibly adjusted, etc., to achieve the shape Ease of control, reduced emission, and large radiation angle coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The present invention is further described by taking wheat straw gasification gas as an example as follows:

[0046] Using wheat straw gasification gas as fuel, its component volume percentage is: H 2 19.5%, CO 19.8%, CH 4 5.2%, CO 2 12.1%, N 2 39.4%, low calorific value of 6019kJ / m 3 , The rated thermal load of a single burner is 125kW. The biomass gas burner with adjustable flame length is installed on the furnace head of the slab heating furnace. Under the condition of constant heat load, the heating process of near burning and far burning can be realized by adjusting the flame length.

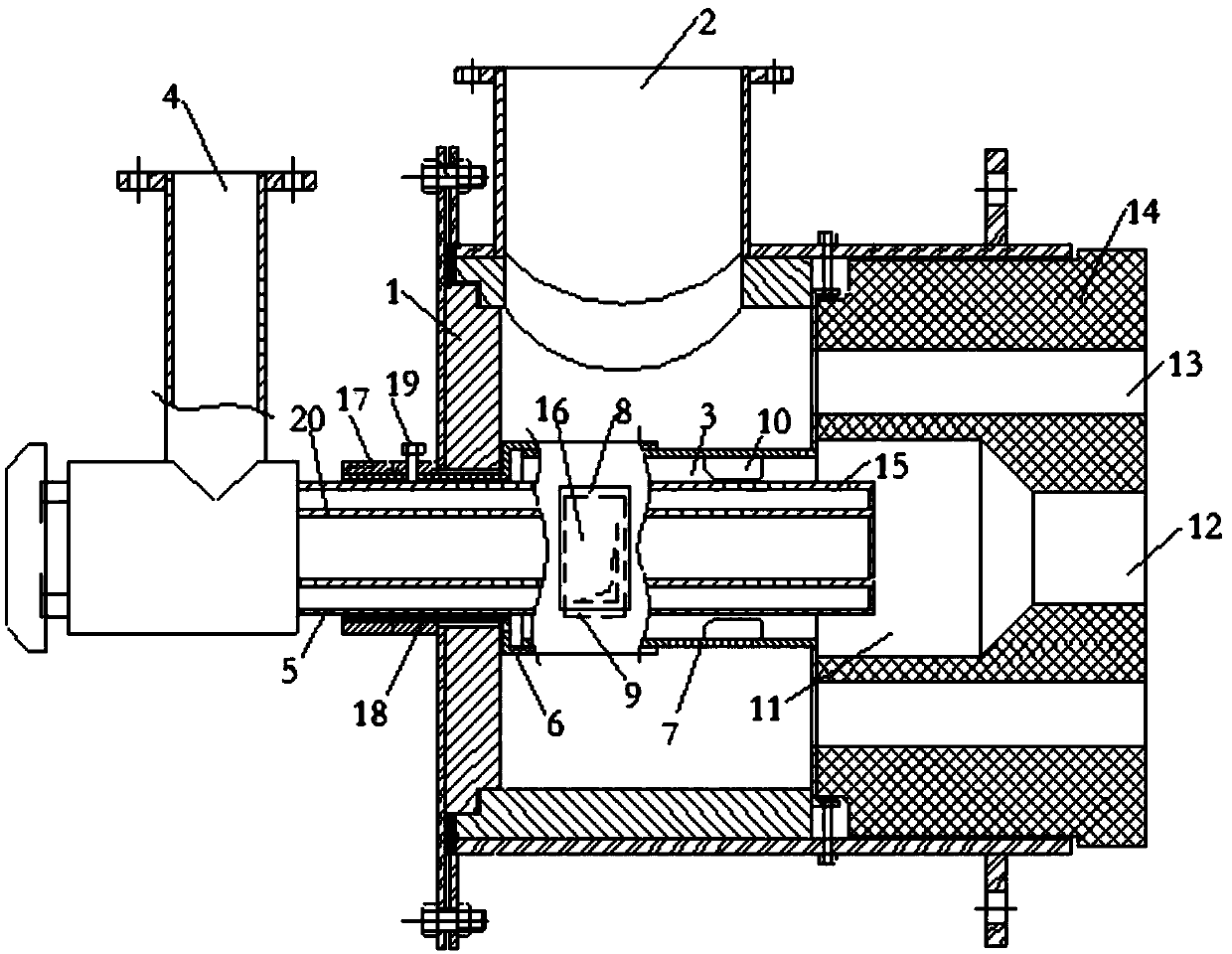

[0047] Take the air consumption coefficient as 1.02, and calculate the required flow rate of wheat straw gasification gas and combustion-supporting air through combustion calculation. Based on this, make burner shell 1, air inlet pipe 2, gas inlet pipe 4, gas nozzle 5, Movable air cover 6, fixed air cover 7, first air port 8, second air port 9, inner burner brick 14, air rin...

Embodiment 2

[0050] Take the gasification gas of dry branches as fuel as an example to further illustrate the present invention:

[0051] Using dry branch gasification gas as fuel, its component volume percentage is: H 2 22.5%, CO 18.8%, CH 4 7.2%, CO 2 14.1%, N 2 37.4%, low calorific value of 6217kJ / m 3 , The rated thermal load of a single burner is 250kW. Preparation of dry branch gasification gas burner with adjustable flame length Installed on the burner head of the billet heating furnace, under the condition of constant heat load, the heating process of near burning and far burning can be realized by adjusting the length of the flame.

[0052] Take the air consumption coefficient as 1.03, calculate the flow rate of gasification gas and combustion-supporting air required by combustion calculation, and based on this, make burner shell 1, air inlet pipe 2, gas inlet pipe 4, and gas nozzle 5 , movable wind cover 6, fixed wind cover 7, first tuyere 8, second tuyere 9, inner burner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com