Full-seam mining coal mining machine and coal mining method

A coal shearer and full-height mining technology, which is applied to cutting machinery, earth drilling, cutting machinery, etc., can solve the problems of difficult coal mining in narrow and small working faces, increased energy consumption of coal breaking, and clumsy structure, etc., and achieves significant economic benefits and social benefits, improve recovery rate, improve safety and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

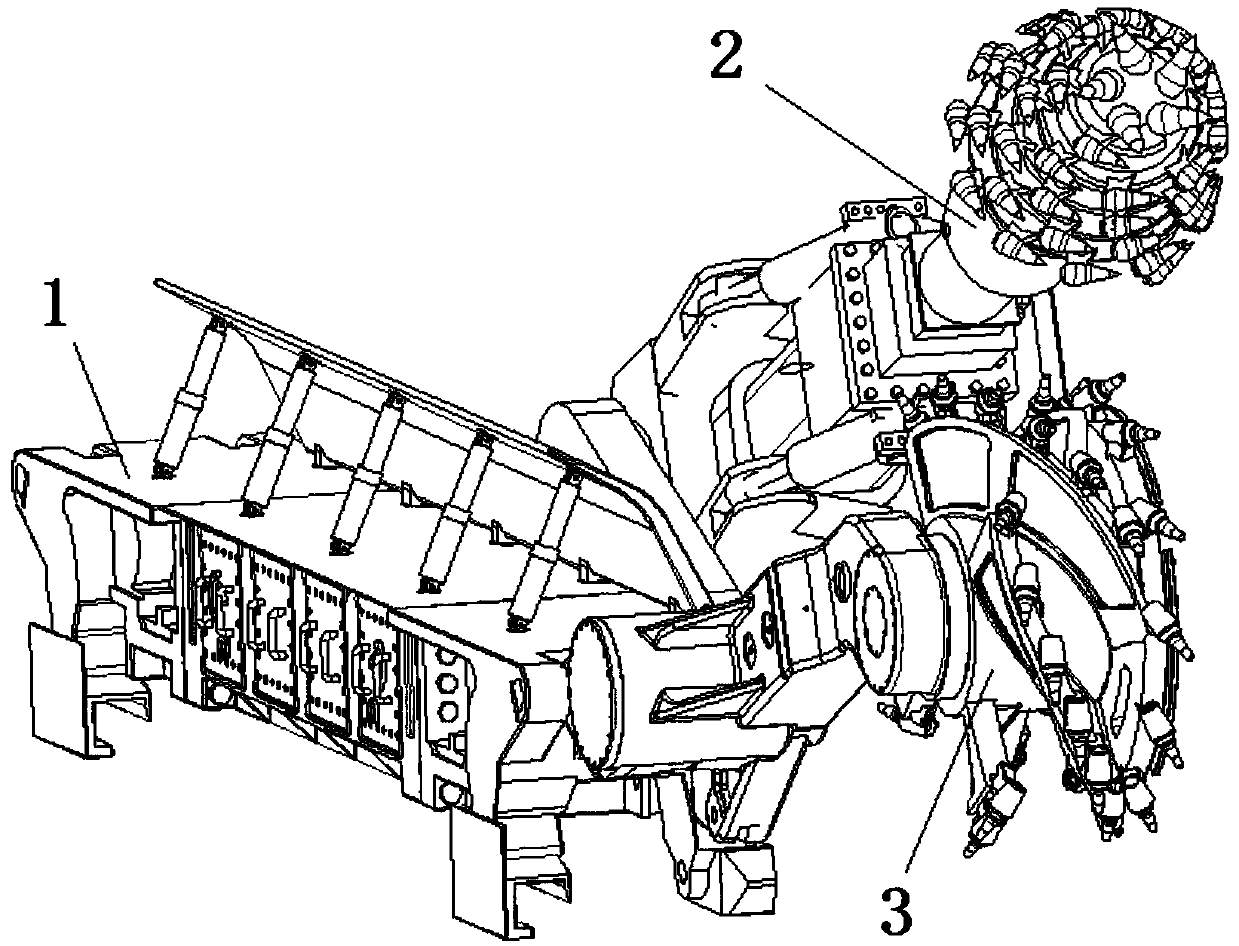

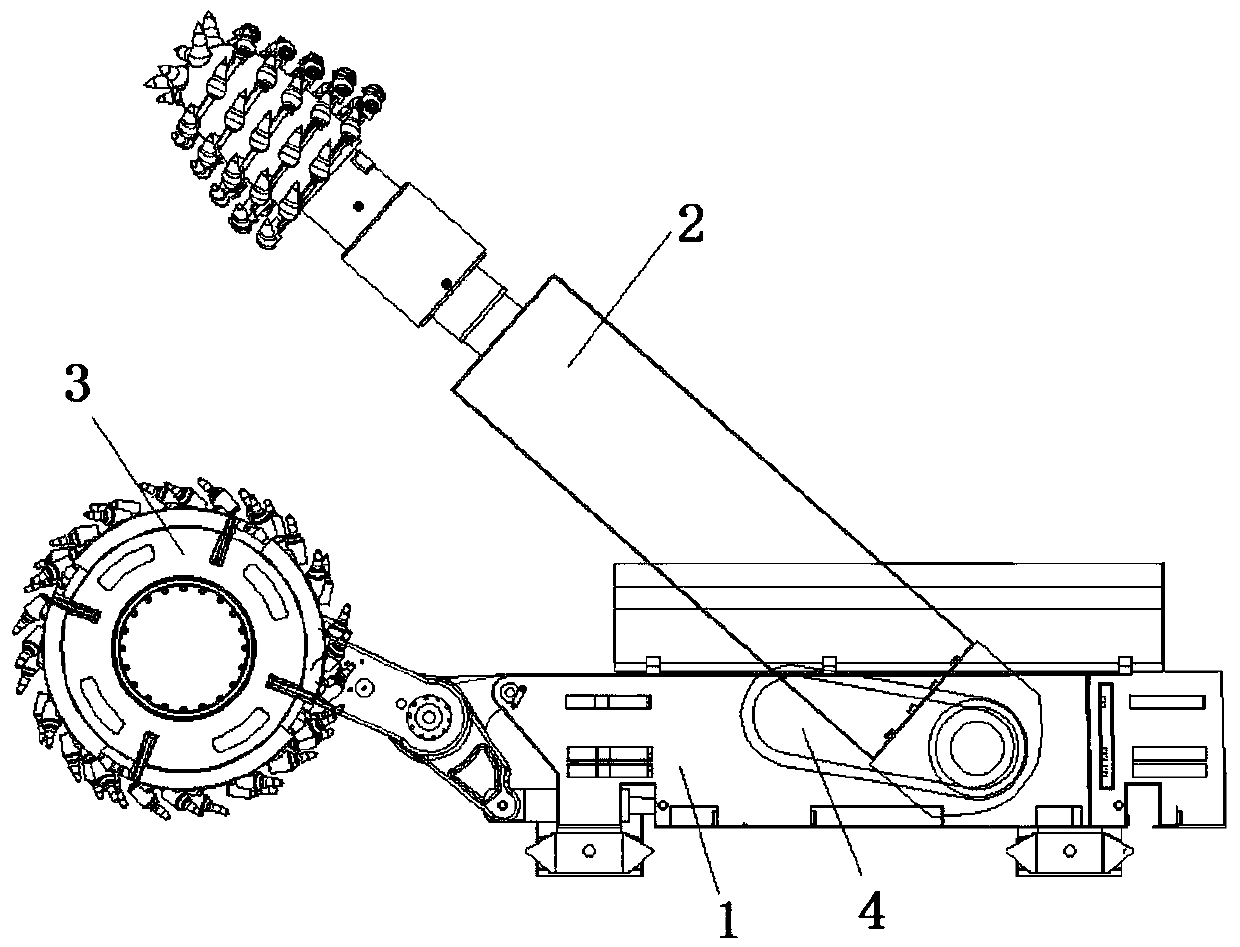

[0032] The present invention proposes a full-height coal mining machine and a coal mining method. In order to make the advantages and technical solutions of the present invention clearer and clearer, the present invention will be further described in conjunction with specific examples below.

[0033] The full-height coal mining machine and coal mining method of the present invention are proposed based on the theory of "cutting the inside and laying the outside out". Under the condition of ensuring low power, the full height of 6m can be realized at one time. It is based on tensile stress coal breaking, clever use of mine pressure, can greatly reduce energy consumption, and reciprocating two-way coal cutting, the work efficiency is significantly improved, not only can be used for conventional working face mining, but also suitable for recycling edge coal and fracture under complex geology Coal mining within the layer and ultra-short working face mining are green, environmentally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com