Distributed self-monitoring pre-stressed composite rib based on long-scale-distance fiber grating

A fiber grating and composite rib technology, applied in the field of distributed self-monitoring prestressed composite rib, can solve problems such as sensor damage, limited use scenarios, and inability to take advantage of composite material performance, reduce maintenance costs, enhance long-term durability and The effect of safety and reliability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

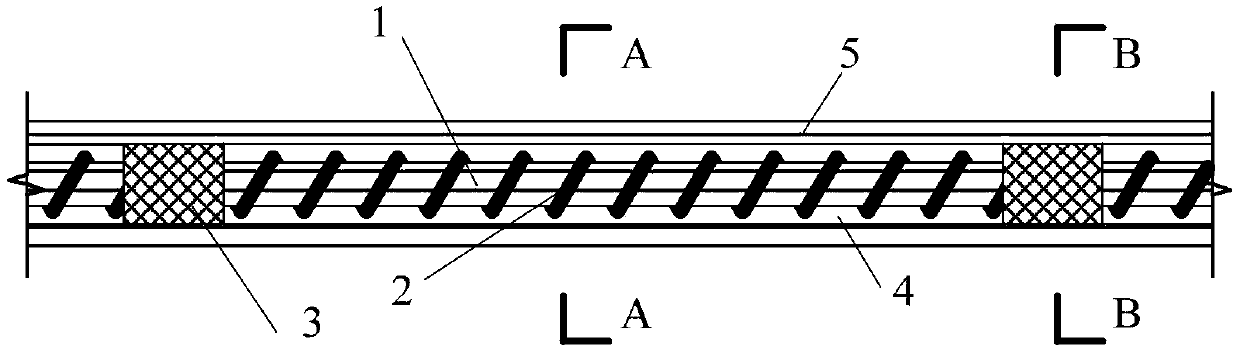

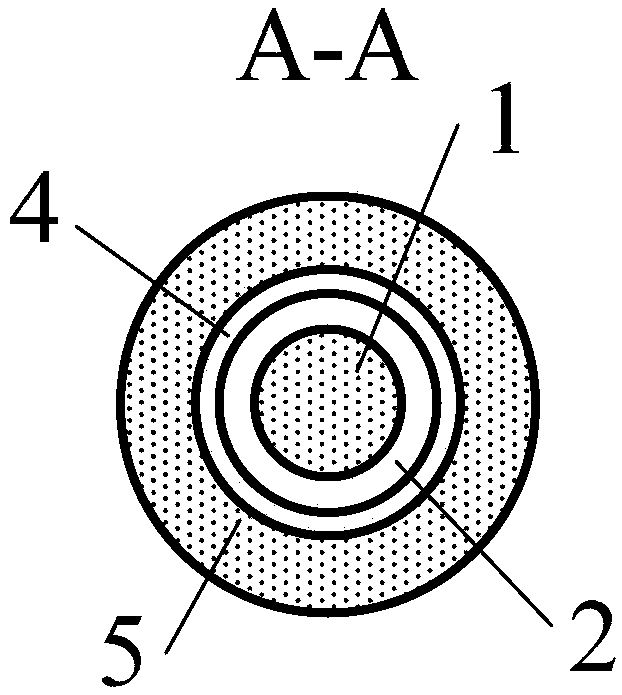

[0020] Such as figure 1 As shown, a distributed self-monitoring prestressed composite bar based on long-gauge fiber Bragg grating of the present invention includes the following parts: core composite bar 1, long-gauge fiber Bragg grating 2, resin coating 3 in anchoring area, and optical fiber protection tube 4. Composite reinforcement shell5. The core composite rib 1 is covered with multiple sections of optical fiber protection tubes 4, and the resin coating 3 in the anchoring area is arranged between each section of the fiber protection tubes 4; the core composite rib 1 is wound with a long-gauge optical fiber grating 2, and a long-gauge optical grating 2 is located between the core composite rib 1 and the optical fiber protection tube 4; a composite rib shell 5 is arranged outside the optical fiber protection tube 4, and the diameter of the core composite rib is not less...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com