Electrochromic yarn and preparation method thereof

An electrochromic and thermochromic ink technology, applied in the field of color-changing yarns, can solve the problems of complex preparation process, poor conductivity, and high polymer durability, and achieves simple preparation method, simple control method and low preparation cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A preparation method of electrochromic yarn, comprising the following steps:

[0023] S1. Utilize ethanol to clean the oil stains and impurities on the surface of the cotton fiber roving sliver, repeat the operation a 6 times to obtain the carbon nanotube / fiber roving sliver; the operation a is to immerse the fiber roving sliver in the dispersed aqueous solution of the carbon nanotube for 10 -30min, then dry; the concentration of carbon nanotubes in the dispersed aqueous solution is 0.05wt%;

[0024] S2. Spinning the carbon nanotube / fiber roving sliver to obtain the carbon nanotube / fiber composite yarn, wherein the twist of the yarn during spinning is 647T / m;

[0025] S3. wrapping ordinary white fibers on the surface of carbon nanotube / fiber composite yarn to obtain carbon nanotube wrapped yarn;

[0026] S4. Coating the thermochromic ink on the surface of the carbon nanotube-wrapped yarn, and drying at room temperature.

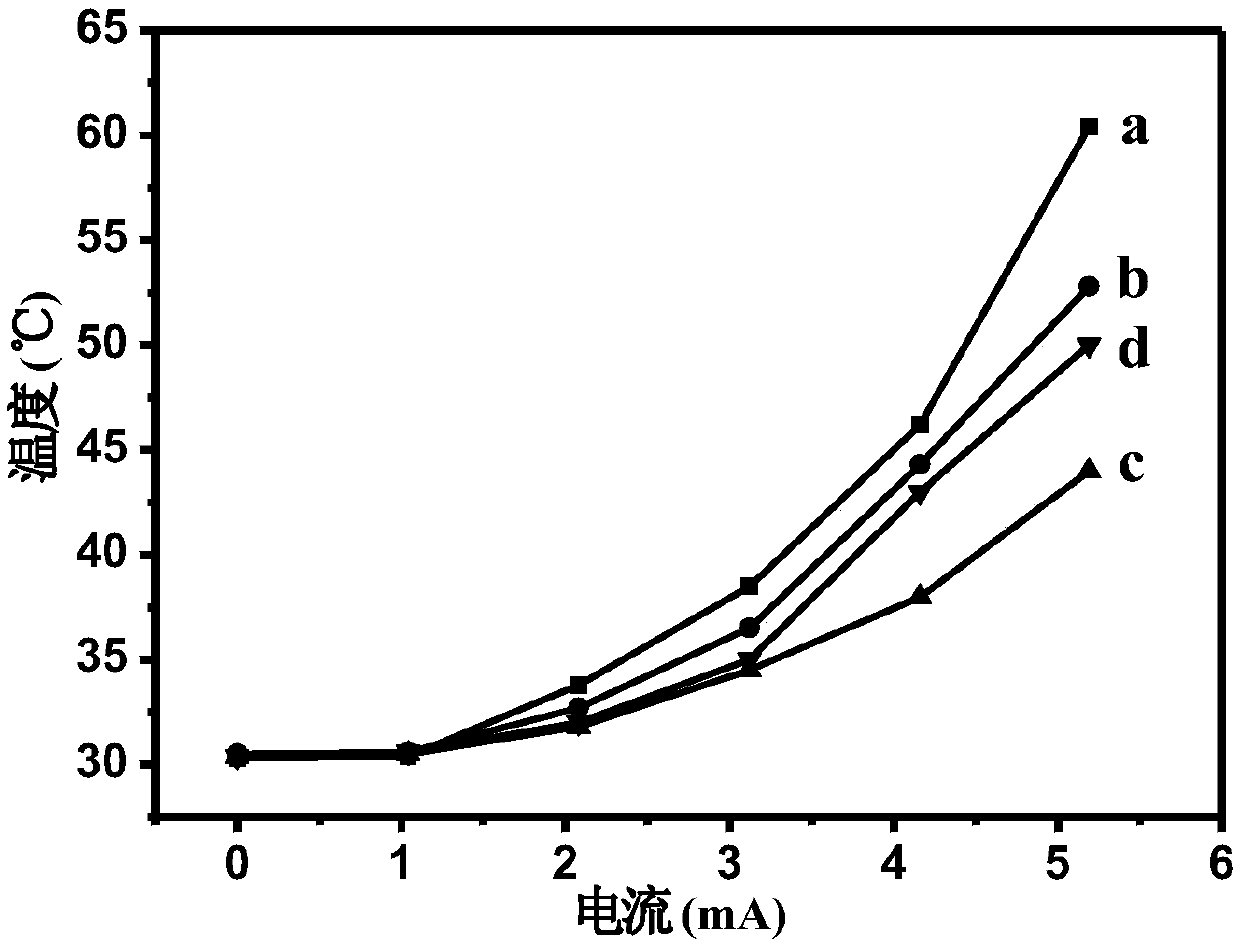

[0027] The detected resistance value of the el...

Embodiment 2

[0031] A preparation method of electrochromic yarn, comprising the following steps:

[0032] S1. Utilize ethanol to clean the oil and impurities on the surface of the cotton fiber roving sliver, repeat the operation a once to obtain the carbon nanotube / fiber roving sliver; the operation a is to immerse the fiber roving sliver in the dispersed aqueous solution of the carbon nanotube for 10 -30min, then dry; the concentration of carbon nanotubes in the dispersed aqueous solution is 0.05wt%;

[0033] S2. Spinning the carbon nanotube / fiber roving sliver to obtain a carbon nanotube / fiber composite yarn, wherein the twist of the yarn during spinning is 647T / m;

[0034] S3. wrapping ordinary white fibers on the surface of carbon nanotube / fiber composite yarn to obtain carbon nanotube wrapped yarn;

[0035] S4. Coating the thermochromic ink on the surface of the carbon nanotube-wrapped yarn, and drying at room temperature.

[0036] The resistance value of the detected electrochromic...

Embodiment 3

[0040] A preparation method of electrochromic yarn, comprising the following steps:

[0041] S1. Utilize ethanol to clean the oil stains and impurities on the surface of the cotton fiber roving sliver, repeat the operation a 6 times to obtain the carbon nanotube / fiber roving sliver; the operation a is to immerse the fiber roving sliver in the dispersed aqueous solution of the carbon nanotube for 10 -30min, then dry; the concentration of carbon nanotubes in the dispersed aqueous solution is 0.025wt%;

[0042] S2. Spinning the carbon nanotube / fiber roving sliver to obtain a carbon nanotube / fiber composite yarn, wherein the twist of the yarn during spinning is 647T / m;

[0043] S3. wrapping ordinary white fibers on the surface of carbon nanotube / fiber composite yarn to obtain carbon nanotube wrapped yarn;

[0044] S4. Coating the thermochromic ink on the surface of the carbon nanotube-wrapped yarn, and drying at room temperature.

[0045] The detected resistance value of the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com