Nitrile rubber compound and preparation method thereof

A technology of nitrile rubber and rubber compound is applied in the field of nitrile rubber compound and its preparation, which can solve the problems of lack of antibacterial properties, short service life of gloves, poor wear resistance, etc., so as to shorten the dipping time and improve the protective effect. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

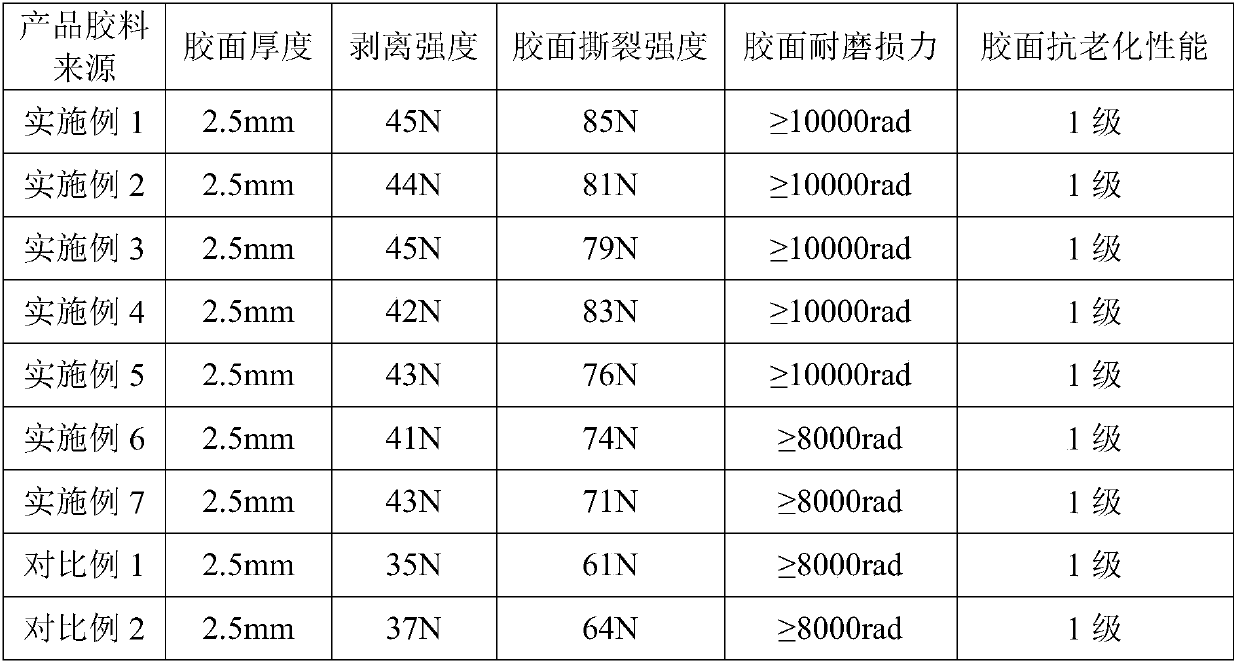

Examples

Embodiment 1

[0023] A kind of preparation method of acrylonitrile-butadiene rubber compound that present embodiment provides, comprises the steps:

[0024] (1) Dissolve the rare earth oxide and monazite powder in concentrated hydrochloric acid, acidify, dry and then mix and grind to obtain soluble anion crystals, wherein the weight ratio of monazite powder and rare earth oxide is 1:1, and the rare earth oxide is oxidized Lanthanum, yttrium oxide, and terbium oxide are mixed according to a weight ratio of 1:0.3:0.05; water-soluble anion crystals and water are mixed into an anion stock solution according to a weight ratio of 1:20; the following raw materials are weighed in parts by weight: D 100 parts of nitrile rubber, 2.8 parts of carbon black N330, 16.4 parts of azodicarbonamide, 3.2 parts of antioxidant RD, 5 parts of plasticizer DOP, 35 parts of negative ion stock solution;

[0025] (2) Mix nitrile rubber, azodicarbonamide, antioxidant RD, and plasticizer DOP according to the formula to...

Embodiment 2

[0027] A kind of preparation method of acrylonitrile-butadiene rubber compound that present embodiment provides, comprises the steps:

[0028] (1) Dissolve the rare earth oxide and monazite powder in concentrated hydrochloric acid, acidify, dry and mix and grind to obtain soluble anion crystals, wherein the weight ratio of monazite powder and rare earth oxide is 0.5:1, and the rare earth oxide is oxidized Lanthanum, yttrium oxide, and terbium oxide are mixed in a weight ratio of 1:0.2:0.01; water-soluble anion crystals and water are mixed in a weight ratio of 1:50 to form an anion stock solution; the following raw materials are weighed in parts by weight: D 80 parts of nitrile rubber, 1 part of carbon black N330, 10 parts of azodicarbonamide, 1 part of antioxidant RD, 3 parts of plasticizer DOP, 20 parts of negative ion stock solution;

[0029] (2) Mix nitrile rubber, azodicarbonamide, antioxidant RD, and plasticizer DOP according to the formula to obtain a slurry; add carbon ...

Embodiment 3

[0031] A kind of preparation method of acrylonitrile-butadiene rubber compound that present embodiment provides, comprises the steps:

[0032] (1) Dissolve rare earth oxides and monazite powder in concentrated hydrochloric acid, acidify, dry and mix and grind to obtain soluble anion crystals, wherein the weight ratio of monazite powder and rare earth oxides is 2:1, and the rare earth oxides are oxidized Lanthanum, yttrium oxide, and terbium oxide are mixed according to the weight ratio of 1:0.5:0.1; water-soluble anion crystals and water are mixed according to the weight ratio of 1:10 to form anion stock solution; the following raw materials are weighed in parts by weight: D 120 parts of nitrile rubber, 5 parts of carbon black N330, 20 parts of azodicarbonamide, 5 parts of antioxidant RD, 10 parts of plasticizer DOP, 40 parts of negative ion stock solution;

[0033] (2) Mix nitrile rubber, azodicarbonamide, antioxidant RD, and plasticizer DOP according to the formula to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com